Optimization Solutions for Irregular BGA Solder Points on PCB Boards

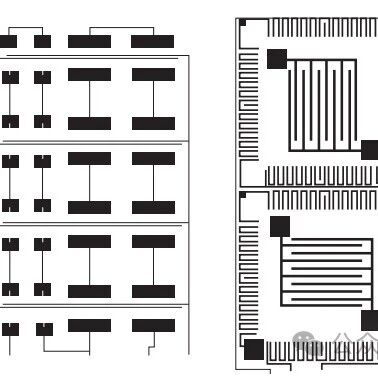

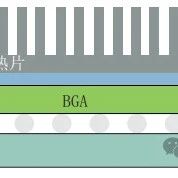

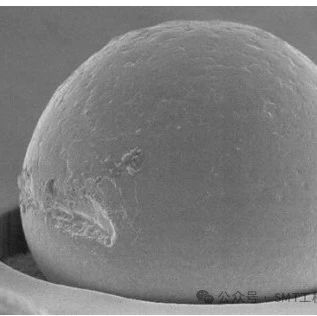

The design of BGA (Ball Grid Array) on PCB boards is very common in the industry, and the issue of irregular BGA sizes can severely affect the soldering quality and electrical performance of PCBs. To effectively improve this issue, it is necessary to address it from the aspects of design and manufacturing processes.1. Package Design1. … Read more