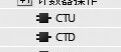

Materials as the Core Competitiveness of 3D Printing

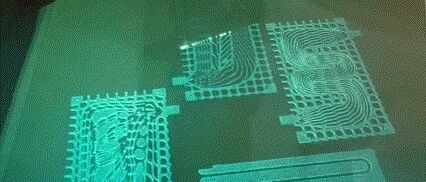

The 3D printing market has become a battleground for materials. Stratasys maintains a strong position in proprietary thermoplastic materials, while 3D Systems dominates in photopolymer resins and metal powders. HP has carved out a niche market with its specialized powders optimized for Multi-Jet Fusion technology. 3D printing companies typically sell printers and provide software and … Read more