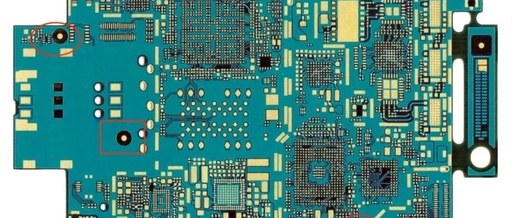

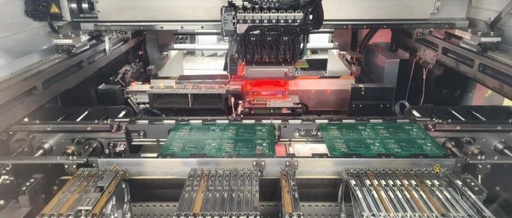

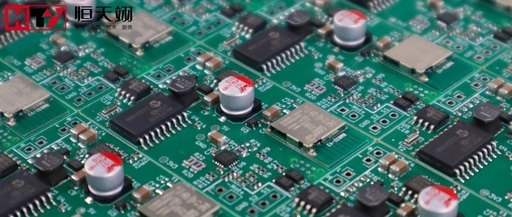

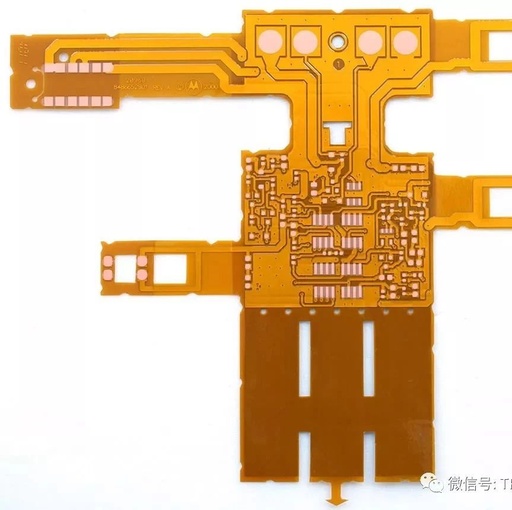

Modern SMT PCB and SMT Assembly Technology

The “Electronic Training Technology Tutorial: Modern SMT PCB and SMT Assembly Technology” includes basic practical skills training, radio practice training, analog circuit practice training, digital circuit practice training, and microcontroller practice training. It emphasizes the cultivation of practical skills, combining theory with practice, such as knowledge of common electronic components and measurement, design and drawing … Read more