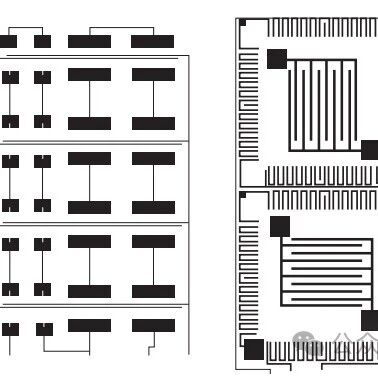

Achieving Assembly of Over 60 Unconventional Through-Hole Components on Server Circuit Boards? FuzionOF Can Do It.

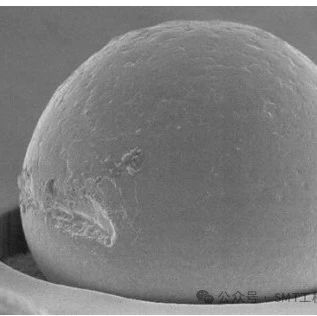

Click the blue text to follow us When manufacturers face the production of blade servers, the numerous unconventional components on the PCB often prevent full automation, with some components still requiring manual operation, resulting in a yield rate below 98%. To find a comprehensive automation solution, while improving product yield, the following requirements must be … Read more