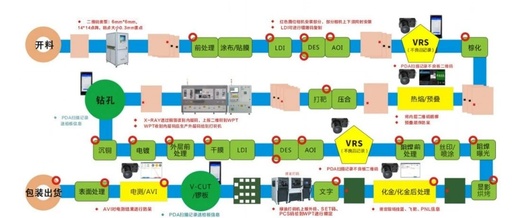

Analysis of Three Major PCBA Process Steps

ABC Sharing Session No. 96Sharing Topic: Analysis of PCBA Process StepsSharing Time: 2020.10.14 Speaker: ABC Xiao VRecorder: ABCTinaEditor: Xiao GangTotal Word Count: 5626 words / Reading Time 6 minutesThis is the first session of the ABC electronic product cost analysis series:1. Analysis of PCBA Process Steps (This Sharing)2. Analysis of PCBA Processing Cost Factors3. Classification … Read more