In-Depth Analysis of Chip Decapsulation Technology

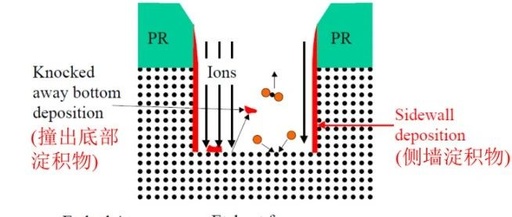

😶🌫️ Always staring at the phone So dizzy! 😇 Click 🎧 to listen and let’s sharpen our ears together 👂 How to unveil the “black box” of a chip without damaging the silicon wafer? Chip decapsulation is a critical step in failure analysis, requiring precise removal of packaging materials at the micron scale while protecting … Read more