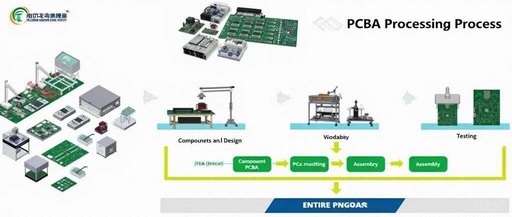

Methods for Estimating PCBA Costs

When designing electronic products, it is often necessary to evaluate hardware costs. What components make up hardware costs? They mainly consist of the prices of components, PCBs, and SMT, which together constitute the cost of PCBA. In other words, calculating hardware costs primarily involves calculating the cost of PCBA. Let’s learn about the methods for … Read more