Click the blue text

Follow us

In the wave of Industry 4.0, the electronic manufacturing industry is undergoing a profound transformation from “mass production” to “customized production.” The multi-variety small-batch PCBA production model, with its advantage of flexibly responding to market demands, is gradually becoming the standard in fields such as consumer electronics, industrial control, and medical devices. However, behind this seemingly ideal production method lie numerous industry challenges. 1. The chain reaction caused by frequent “line changes” A production supervisor from a smart wearable device manufacturer once admitted: “Our production line has to complete more than 8 product switches every day, akin to having a chef run back and forth between a Sichuan restaurant and a French bistro.” This frequent line change directly leads to three serious consequences: the production schedule becomes meaningless, overall equipment effectiveness (OEE) drops below 50%, and the on-time delivery rate hovers around 65%. More troubling is that when urgent orders coincide with equipment debugging anomalies, the production line often falls into a vicious cycle of “debugging while producing.” 2. The phenomenon of “missed quality control” The traditional electronic manufacturing industry’s “3σ” quality management system frequently fails in small-batch scenarios. A quality director from an automotive electronics company revealed: “For an order of 50 sets, the conventional sampling ratio allows for only 5 sets to be inspected, but defects in solder joints were found in the uninspected batches.” This sampling blind spot, compounded by frequent adjustments to process parameters, results in a first-piece defect rate that is 3-5 times higher than that of traditional production lines. Even more severe is that when quality traceability occurs, the process data of different batches of products is often mixed and indistinguishable. 3. The “tightrope walking” dilemma of the supply chain Material management is evolving into a high-difficulty balancing act: an industrial control board manufacturer’s inventory list shows that 120 specifications of 0402 packaged resistors are needed, but the single purchase quantity is less than a thousand pieces. This “ant搬家” style of procurement leads to three major contradictions: low willingness of suppliers to cooperate, over 30% of stagnant materials, and frequent line stoppages due to material shortages. Even more concerning is that the supply cycle for certain specialized chips has extended to 52 weeks, directly threatening the feasibility of production plans. 4. The “metamorphosis” challenge of process adaptation When the same production line needs to accommodate products ranging from consumer-grade to automotive-grade, process control faces severe tests. Records from a medical device PCBA workshop show that switching production from a ventilator control board to a blood glucose meter mainboard requires adjustments to 37 process parameters and the replacement of 15 types of fixtures. This high frequency of process changes not only reduces equipment stability but also makes it difficult for process knowledge to be effectively retained, creating a vicious cycle of “producing while forgetting.” 5. The “iceberg effect” of hidden costs Beyond the visible direct costs, three major hidden costs are eroding corporate profits: personnel skill reshaping costs (approximately 200 hours/person per year for training), trial-and-error costs (with a new product introduction scrap rate as high as 12%), and opportunity costs (potential orders lost due to capacity fluctuations). A financial report from a listed EMS company shows that its small-batch business gross margin is 8-10 percentage points lower than that of large-batch business, with the main losses stemming from these hidden costs. In the face of these industry challenges, leading companies are exploring solutions: implementing digital scheduling systems for “minute-level” line changes, adopting AOI+AI full inspection solutions, building supplier collaboration cloud platforms, and developing intelligent process decision systems. Practices from a smart home PCBA factory have demonstrated that by implementing flexible intelligent manufacturing solutions, product switching time was reduced by 70%, quality costs decreased by 40%, and inventory turnover rate increased threefold. These breakthrough advancements herald the arrival of an efficiency revolution in multi-variety small-batch production.

In this “flexible breakthrough battle” of manufacturing, companies need to establish four core capabilities: agile response capability (from market demand to production delivery), process stability capability (balancing quality and efficiency), knowledge management capability (digitizing process experience), and ecological collaboration capability (deep integration of the supply chain). Only by overcoming these key bottlenecks can the true commercial value of small-batch production be unleashed, gaining a differentiated competitive advantage in the intelligent era.

Jiangxi Intelli Electronics Technology Co., Ltd.

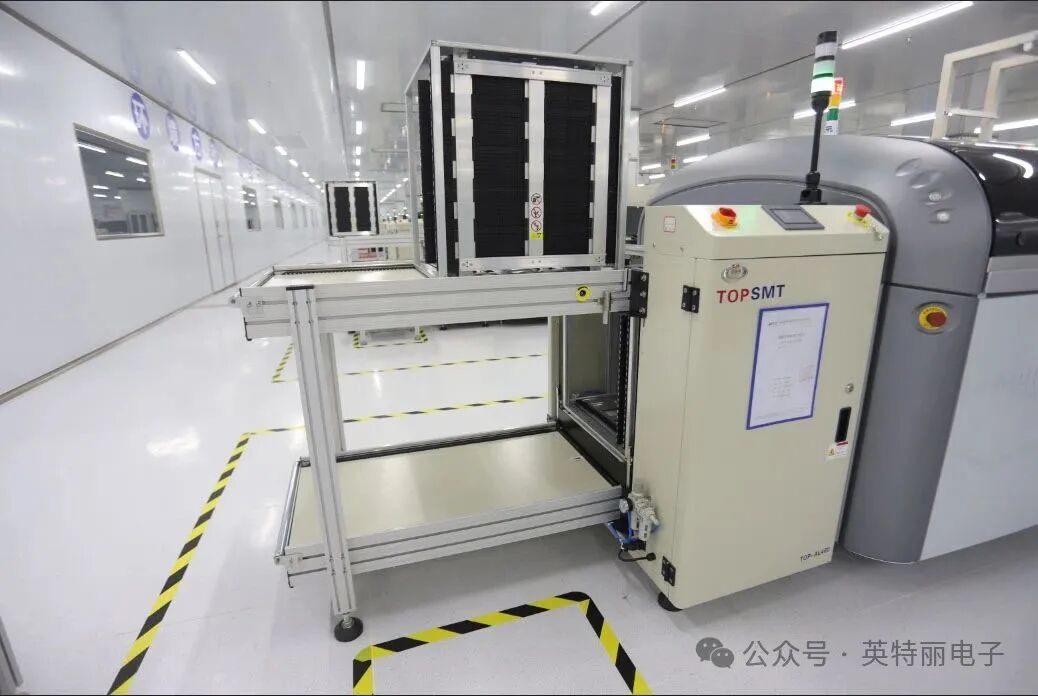

Jiangxi Intelli Electronics Technology Co., Ltd. was established in May 2016, located in the talented and beautiful land of Jiangxi Province, Fuzhou City, Linchuan District. Jiangxi Intelli Electronics Technology Co., Ltd. currently has a factory area of 30,000 square meters, 24 SMT production lines, 8 plug-in lines, 4 wave soldering lines, 8 assembly lines, 4 packaging lines, with a total investment of 1 billion yuan, equipped with an advanced and complete digital management system, dedicated to building an Industry 4.0 smart factory.

Business inquiries: Mr. Li 17870016160

Company phone: 0794-7878288Company fax: 0794-7878288Email: [email protected]

Company website: www.intelli40.comAddress: Building 8-9, Linchuan High-tech Industrial Park, Fuzhou City, Jiangxi Province

Intelli Electronics

Scan the QR code | Follow us

WeChat ID | intelli40