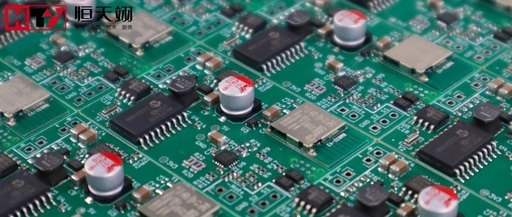

PCBA Visual AI Inspection Technology: The Intelligent Engine of Future Manufacturing

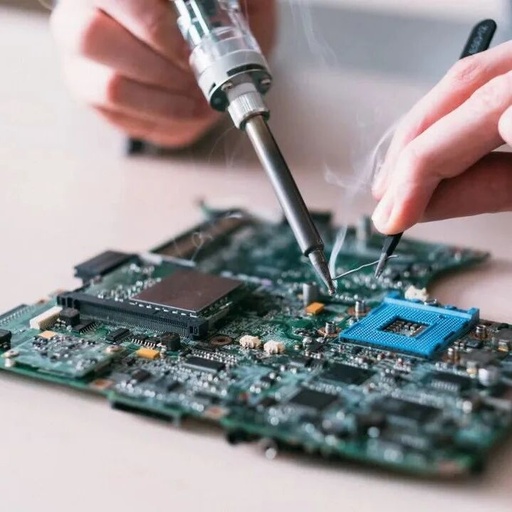

Click the blue text above to follow us With the continuous development of the electronic manufacturing industry, the requirements for production processes are becoming increasingly refined. Visual inspection, as an important part of the inspection process, traditional manual inspection methods are not only inefficient but also prone to human error. In recent years, the topic … Read more