Traditional thermal sink materials (such as W/Cu, Mo/Cu, and SiC/Al) generally have thermal conductivities below 200 W/(m·K), making it difficult to meet the heat dissipation requirements of high-power devices (such as GaN and SiC).

Carbon materials represented by diamond and graphene, with their ultra-high thermal conductivity (diamond reaches 2200 W/(m·K)) and low thermal expansion coefficient (diamond is only 1.2×10-6/K), have become the core breakthrough for the fourth generation of thermal sink materials.

However, single carbon materials have shortcomings: graphite has low compressive strength and is prone to powdering, while diamond films are limited in size and are expensive. By using metal matrix composite technology (such as diamond-copper and graphite-aluminum), these carbon materials can be combined with metals to integrate high thermal conductivity and adjustable low thermal expansion coefficients, potentially meeting the urgent demand for fourth-generation carbon/metal thermal sink composite materials for high-power semiconductors.

Thermal sinks are a necessity for electronic devices and are key to supporting performance improvements. For every 10 degrees Celsius increase in temperature, the lifespan decreases by 50%, and the performance of thermal sink materials determines the performance and reliability of devices.

With the increasing power and integration of devices such as drones, robots, and AI computing, the demand for high-performance thermal sink materials is becoming increasingly urgent.

The main cooling methods for semiconductor laser packaging include natural convection thermal sink cooling, microchannels, thermoelectric cooling, spray cooling, and heat pipe cooling. Among these, for single-tube semiconductor lasers, natural convection thermal sink cooling is easy to process and assemble, making it the most economical and commonly used cooling method. High thermal conductivity materials are generally used for thermal sinks to expand the natural convection heat dissipation area, thereby increasing the heat dissipation and lowering the temperature of the laser chip.

The majority of heat generated by semiconductor lasers occurs in the active region of the chip, which is conducted through the solder layer, insulation layer, and interface layer to the transition thermal sink and conventional thermal sink, where the conventional thermal sink contacts the cooling medium to form convective heat transfer and dissipate heat.

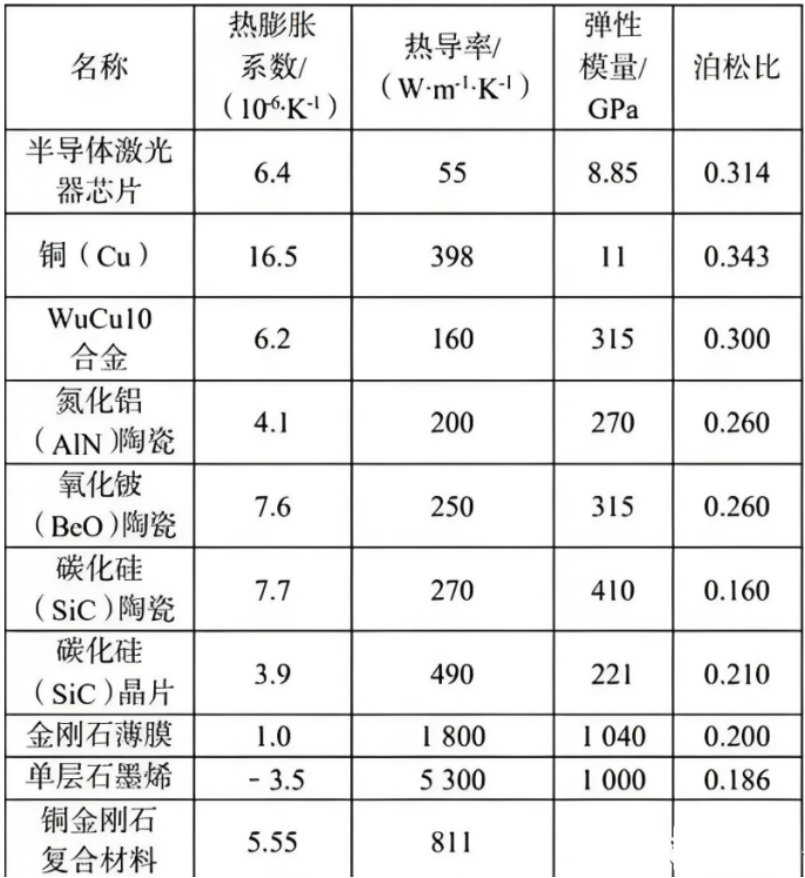

The ideal transition thermal sink material should have high thermal conductivity while matching the thermal expansion coefficient of the laser chip. Copper, known for its high thermal conductivity and electrical conductivity, is commonly used as a thermal sink in semiconductor laser packaging. However, the thermal expansion coefficient of copper differs significantly from that of the chip, which can easily lead to thermal stress and affect the output performance of the laser.

Inserting a transition thermal sink with high thermal conductivity and a thermal expansion coefficient close to that of the chip between the chip and the conventional thermal sink can effectively solve this problem. Commonly used transition thermal sink materials include aluminum nitride ceramics, beryllium oxide ceramics, silicon carbide ceramics, tungsten-copper alloys, silicon carbide wafers, diamond films, and monolayer graphene.

Among these, natural diamond materials have a thermal conductivity of up to 2000 W/(m·K), about five times that of copper, and a small thermal expansion coefficient. Therefore, using diamond, which is both electrically insulating and highly thermally conductive, as a thermal sink for high-power semiconductor lasers is quite ideal. However, due to cost issues, natural diamond cannot be used in semiconductor laser packaging. Currently, diamond is mainly used as thermal sink material in two forms: diamond films (CVD diamond films) and composites of diamond with metals such as copper and aluminum.

Further Reading:

Source: Weihao Chuangxin; Edited by: small J

Disclaimer: The text is intended solely for technical exchange within the industry, aimed at promoting industry development!