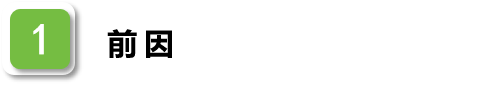

Recently, the project I am responsible for has started mass production, with the first batch planned to produce two hundred sets. During the production testing phase, it was found that seven PCBA boards had issues, with symptoms including: the boards not powering on, no signal on the acquisition channels, and programs unable to download…Upon hearing this news, I felt somewhat nervous. Although small batches had undergone various tests, I was still concerned that if it were a design flaw, the losses could be significant…Fortunately, these were all production issues. Embracing the mindset of summarizing hardware experiences, I compiled these PCBA fault repair strategies.

Recently, the project I am responsible for has started mass production, with the first batch planned to produce two hundred sets. During the production testing phase, it was found that seven PCBA boards had issues, with symptoms including: the boards not powering on, no signal on the acquisition channels, and programs unable to download…Upon hearing this news, I felt somewhat nervous. Although small batches had undergone various tests, I was still concerned that if it were a design flaw, the losses could be significant…Fortunately, these were all production issues. Embracing the mindset of summarizing hardware experiences, I compiled these PCBA fault repair strategies.

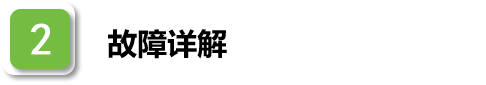

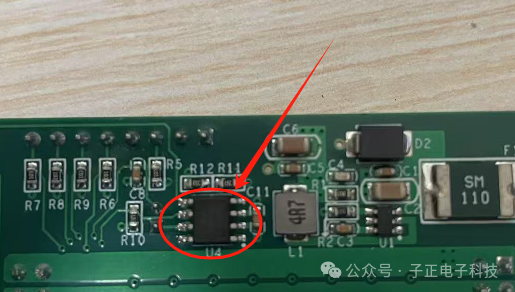

· Fault Analysis (1)Symptoms: Single channel acquisition has no signal;Thought Process: The function of this module is to provide multi-channel current signal acquisition; if other channel signal acquisitions are normal, it is very likely that the signal is not being transmitted to the ADC acquisition chip;Of course, another possibility is that the AD channel corresponding to the IC chip is damaged, leading to no recognition;(In this case, prioritize checking the conditioning circuit for any circuit breakpoints, as the likelihood of a single channel of the AD chip being damaged is low. When encountering packages like QFN that require high manual soldering skills, it is possible that the problem was not resolved and new soldering issues were introduced.)

· Fault Analysis (1)Symptoms: Single channel acquisition has no signal;Thought Process: The function of this module is to provide multi-channel current signal acquisition; if other channel signal acquisitions are normal, it is very likely that the signal is not being transmitted to the ADC acquisition chip;Of course, another possibility is that the AD channel corresponding to the IC chip is damaged, leading to no recognition;(In this case, prioritize checking the conditioning circuit for any circuit breakpoints, as the likelihood of a single channel of the AD chip being damaged is low. When encountering packages like QFN that require high manual soldering skills, it is possible that the problem was not resolved and new soldering issues were introduced.) Conclusion: Following the thought process, I checked from the signal entry point step by step and found that a self-resetting fuse had shifted, with one end not on the pad, causing the signal interruption;Mitigation Plan: In the future, consider increasing the pad size and reducing the center spacing of the pads to avoid the self-resetting fuse shifting due to the tension caused by the solder melting during the reflow process, which could lead to poor soldering.· Fault Analysis (2)Symptoms: The single board does not power on, and the indicator light is off;Thought Process: Based on the design of the power circuit, the external 24V-DC power supply first inputs to the DC-DC isolation power chip on the board, which then outputs to power the various ICs on the board; given this, it can be inferred that the possible reasons are that the DC-DC power supply has no input; or the DC-DC power supply is damaged, having input but no output;Therefore, we first measure whether there is a short circuit at the input of the isolation power supply and whether the input voltage is normal; then measure whether there is a short circuit at the output of the isolation power supply and whether the output voltage is normal;

Conclusion: Following the thought process, I checked from the signal entry point step by step and found that a self-resetting fuse had shifted, with one end not on the pad, causing the signal interruption;Mitigation Plan: In the future, consider increasing the pad size and reducing the center spacing of the pads to avoid the self-resetting fuse shifting due to the tension caused by the solder melting during the reflow process, which could lead to poor soldering.· Fault Analysis (2)Symptoms: The single board does not power on, and the indicator light is off;Thought Process: Based on the design of the power circuit, the external 24V-DC power supply first inputs to the DC-DC isolation power chip on the board, which then outputs to power the various ICs on the board; given this, it can be inferred that the possible reasons are that the DC-DC power supply has no input; or the DC-DC power supply is damaged, having input but no output;Therefore, we first measure whether there is a short circuit at the input of the isolation power supply and whether the input voltage is normal; then measure whether there is a short circuit at the output of the isolation power supply and whether the output voltage is normal; Conclusion: Following the thought process step by step, it was ultimately confirmed that this DC-DC isolation power chip had abnormal output but no short circuit; after repeated study, it was found that this power chip was soldered incorrectly…

Conclusion: Following the thought process step by step, it was ultimately confirmed that this DC-DC isolation power chip had abnormal output but no short circuit; after repeated study, it was found that this power chip was soldered incorrectly… Conclusion: This module’s power input and output were all normal; upon careful observation, it was found that the LED indicator for power in the upper right corner had been knocked off, making it appear as if it was not powered on…(This was the first time encountering such an issue, quite amusing.)Mitigation Plan: Both of these errors were caused by human factors, so feedback needs to be given to the soldering factory to inform them to improve their production processes.· Fault Analysis (3)Symptoms: The MCU cannot download the program;Thought Process: This issue is the most common, but the reasons are also the hardest to pinpoint. One must not assume that the MCU is damaged right away; first, check whether there are any short circuits in all power supply circuits, then check whether the output status of each power supply system is normal, and only then proceed to replace the MCU;

Conclusion: This module’s power input and output were all normal; upon careful observation, it was found that the LED indicator for power in the upper right corner had been knocked off, making it appear as if it was not powered on…(This was the first time encountering such an issue, quite amusing.)Mitigation Plan: Both of these errors were caused by human factors, so feedback needs to be given to the soldering factory to inform them to improve their production processes.· Fault Analysis (3)Symptoms: The MCU cannot download the program;Thought Process: This issue is the most common, but the reasons are also the hardest to pinpoint. One must not assume that the MCU is damaged right away; first, check whether there are any short circuits in all power supply circuits, then check whether the output status of each power supply system is normal, and only then proceed to replace the MCU; Conclusion: Following the thought process step by step, it was discovered that the 3.3V power supply system had a short circuit. Using the elimination method, it was found that a 0.1uF filter capacitor from 3.3V to GND had been damaged.Mitigation Plan: The component damage was most likely due to static electricity, so feedback needs to be given to the production department to ensure compliance with regulations and strict adherence to wearing anti-static wristbands during the production process.

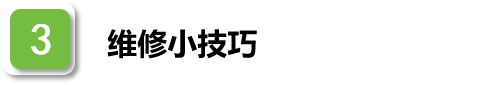

Conclusion: Following the thought process step by step, it was discovered that the 3.3V power supply system had a short circuit. Using the elimination method, it was found that a 0.1uF filter capacitor from 3.3V to GND had been damaged.Mitigation Plan: The component damage was most likely due to static electricity, so feedback needs to be given to the production department to ensure compliance with regulations and strict adherence to wearing anti-static wristbands during the production process. Excluding design defect issues, the PCBA faults encountered during production are relatively easy to handle; the thought process is as follows:· Confirm whether there are short circuits at each level of power supply;· Confirm whether the input and output of each level of power supply are normal;After these two steps, most power-on abnormal issues can be determined;· Use the symptom-based disassembly method;For external input issues, prioritize considering the external input circuit;For IC anomalies, prioritize considering the peripheral circuit of that IC;If it is still difficult to pinpoint the problem based on the above thought process, the last resort is to start from the suspicious points and extend to the overall system, disassembling one by one to determine the problematic components using the elimination method;For power circuit issues, an adjustable power supply can be used for preliminary diagnosis;

Excluding design defect issues, the PCBA faults encountered during production are relatively easy to handle; the thought process is as follows:· Confirm whether there are short circuits at each level of power supply;· Confirm whether the input and output of each level of power supply are normal;After these two steps, most power-on abnormal issues can be determined;· Use the symptom-based disassembly method;For external input issues, prioritize considering the external input circuit;For IC anomalies, prioritize considering the peripheral circuit of that IC;If it is still difficult to pinpoint the problem based on the above thought process, the last resort is to start from the suspicious points and extend to the overall system, disassembling one by one to determine the problematic components using the elimination method;For power circuit issues, an adjustable power supply can be used for preliminary diagnosis;

Set the power supply voltage to the working voltage of the single board and connect it to the single board;

If there is no current, it indicates that the power input circuit of the single board is open;

If the current is abnormally high, it indicates that there is a short circuit in the subsequent stage of the single board;

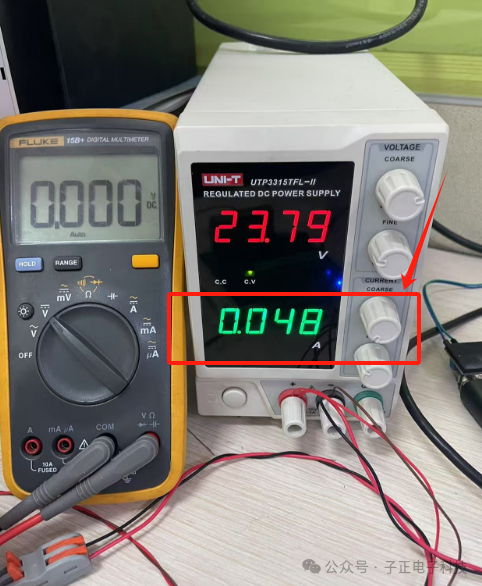

Regarding the disassembly elimination method, the most troublesome issue is how to record the disassembled components; marking each one individually is too cumbersome and time-consuming…

My method is:

First, print out the assembly silkscreen, and during the disassembly process, place the removed components on the silkscreen. Once the damaged components are confirmed, the removed components can still be restored;

Repairing PCBA is not difficult; the core is to remain calm when encountering problems, then think of possible causes based on the symptoms, and finally take action;One must avoid acting blindly without thought or direction, as this may complicate the faults.

Repairing PCBA is not difficult; the core is to remain calm when encountering problems, then think of possible causes based on the symptoms, and finally take action;One must avoid acting blindly without thought or direction, as this may complicate the faults.