Tap the screen with your thumb to follow and not get lost. When you see Old Chen discussing chips, the industry, and humanity, may we meet like the Dabaosod honey every day!The previous two articles “10.1-inch TFT-LCD Display Control Chip” and “3.5-inch TFT-LCD Display Chip” discussed the display control function for output, allowing TFT-LCDs to display text, images, animations, videos, and more, enhancing the beauty of life and showcasing the industrial design beauty of products through beautiful UIs. TFT-LCD is for output, while TP is for input. The TP (touch panel) is often adhered to the TFT-LCD, allowing users to input information into the machine through the panel, forming a human-machine closed-loop interaction. There are two types of TPs: resistive screens and capacitive screens. This article focuses on capacitive screens.Professional Terminology ExplanationLCM:Liquid Crystal DisplayTP:Touch ScreenFrame Adhesive: Double-sided tape attached to the TFT-LCD panelFull Adhesive: OCA glue integrates TP and LCM This is the structural classification of TP. The first letter indicates the surface material (also known as the upper layer), and the second letter indicates the touch screen material (also known as the lower layer), which are bonded together.G+G: SurfaceTempered Glass + Glass material touch screenG+P: Surface tempered glass + PC material touch screenG+F: Surface tempered glass + film material touch screen

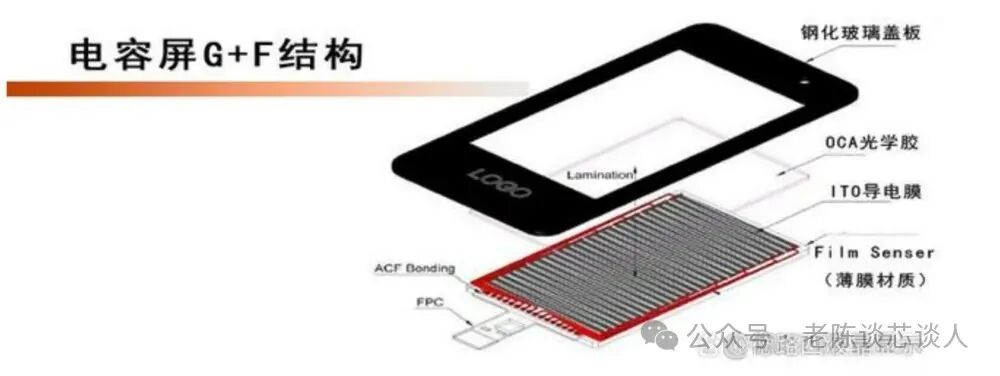

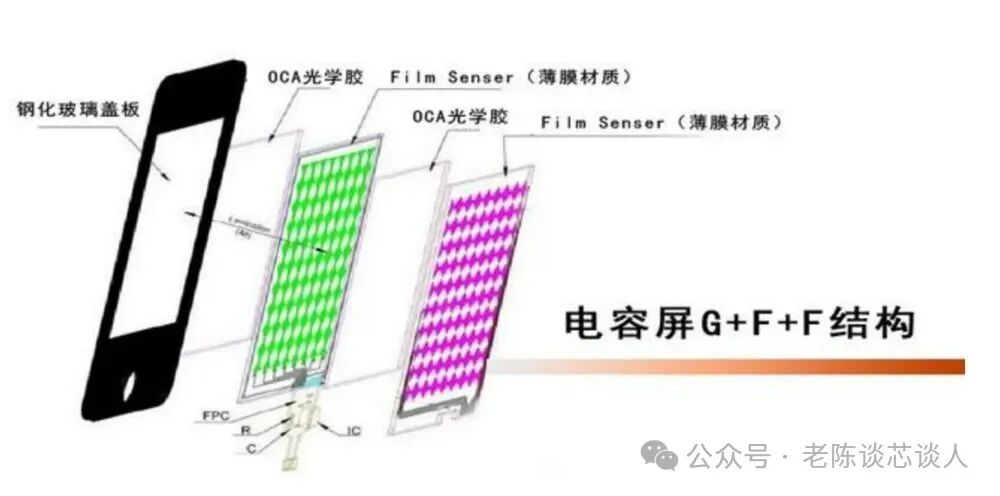

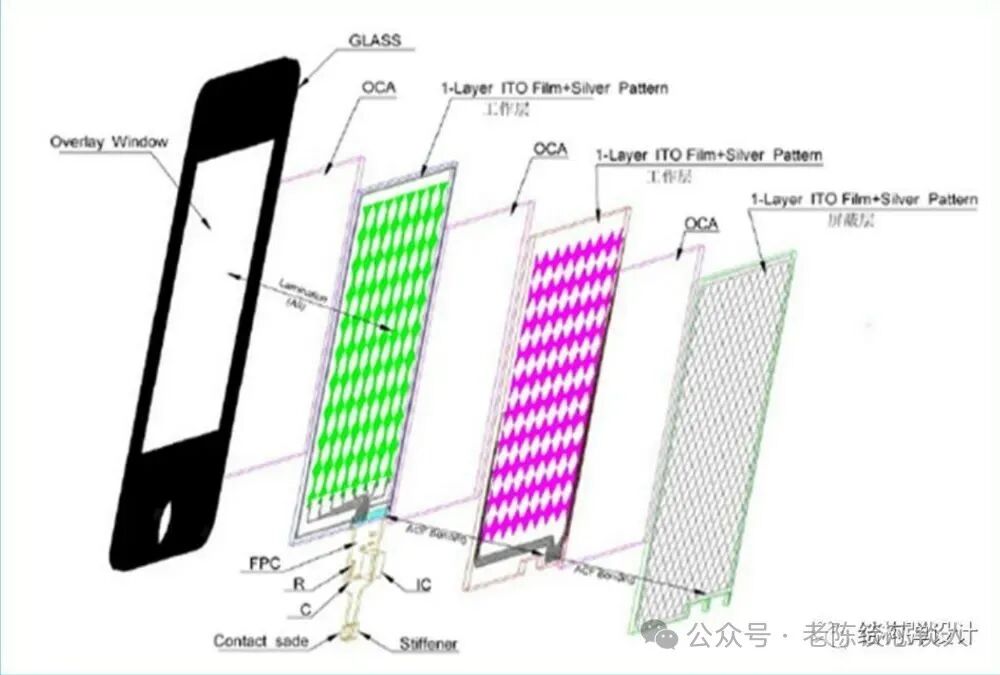

This is the structural classification of TP. The first letter indicates the surface material (also known as the upper layer), and the second letter indicates the touch screen material (also known as the lower layer), which are bonded together.G+G: SurfaceTempered Glass + Glass material touch screenG+P: Surface tempered glass + PC material touch screenG+F: Surface tempered glass + film material touch screen

Surface Capacitive TouchWorking Principle

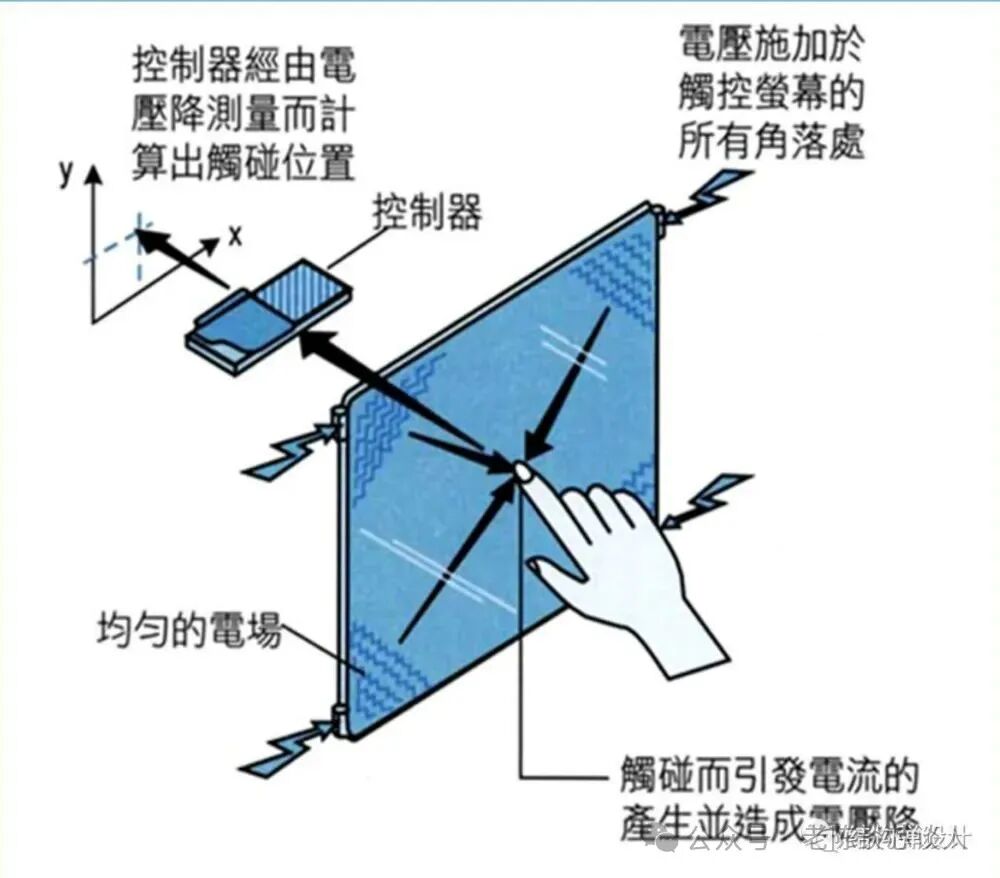

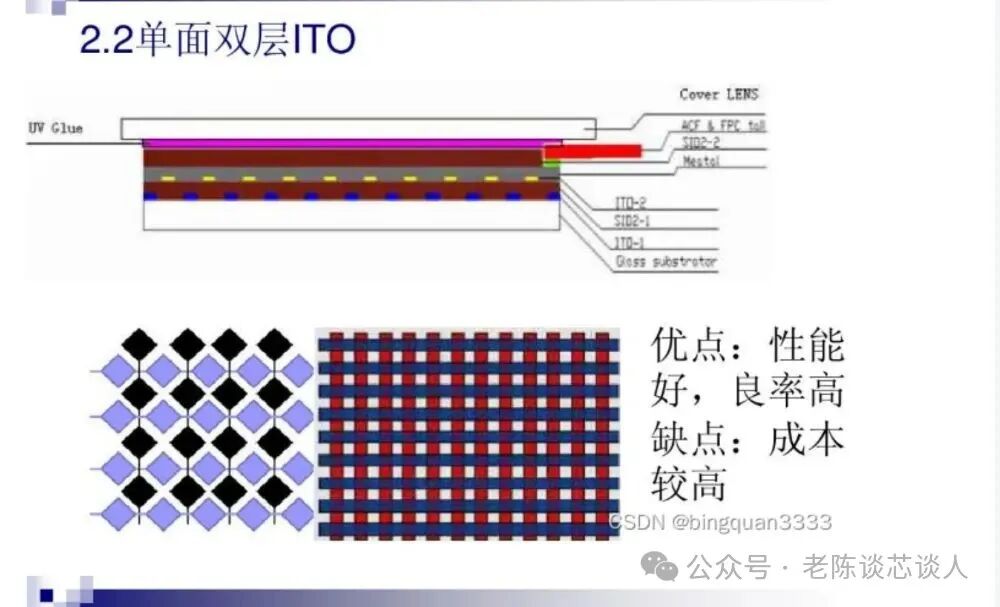

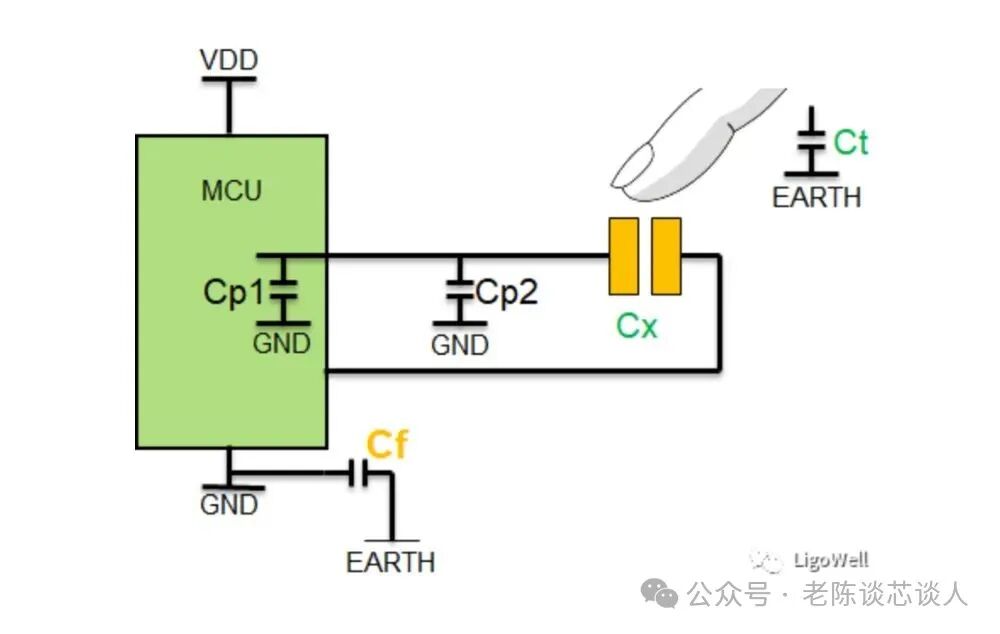

Surface Capacitive TouchWorking Principle When a user touches the screen, due to the human body’s electric field, a coupling capacitance is formed between the finger and the conductor layer. The four edge electrodes generate current that flows to the touch point, and the strength of the current is proportional to the distance between the finger and the electrode. A significant issue with this principle is that it suffers from severe drift; any external interference can cause the touch screen to malfunction. I have not seen this principle applied in any field.Projected Capacitive Touch ScreenWorking PrincipleBasic Principle: The touch screen uses multiple layers of ITO to form a matrix distribution, intersecting along the X and Y axes, functioning as a capacitive matrix. When a finger touches the screen, the change in capacitance at the touch point can be detected through scanning the X and Y axes, allowing the calculation of the finger’s position. Based on this architecture, projected capacitive touch can achieve multi-touch operations.

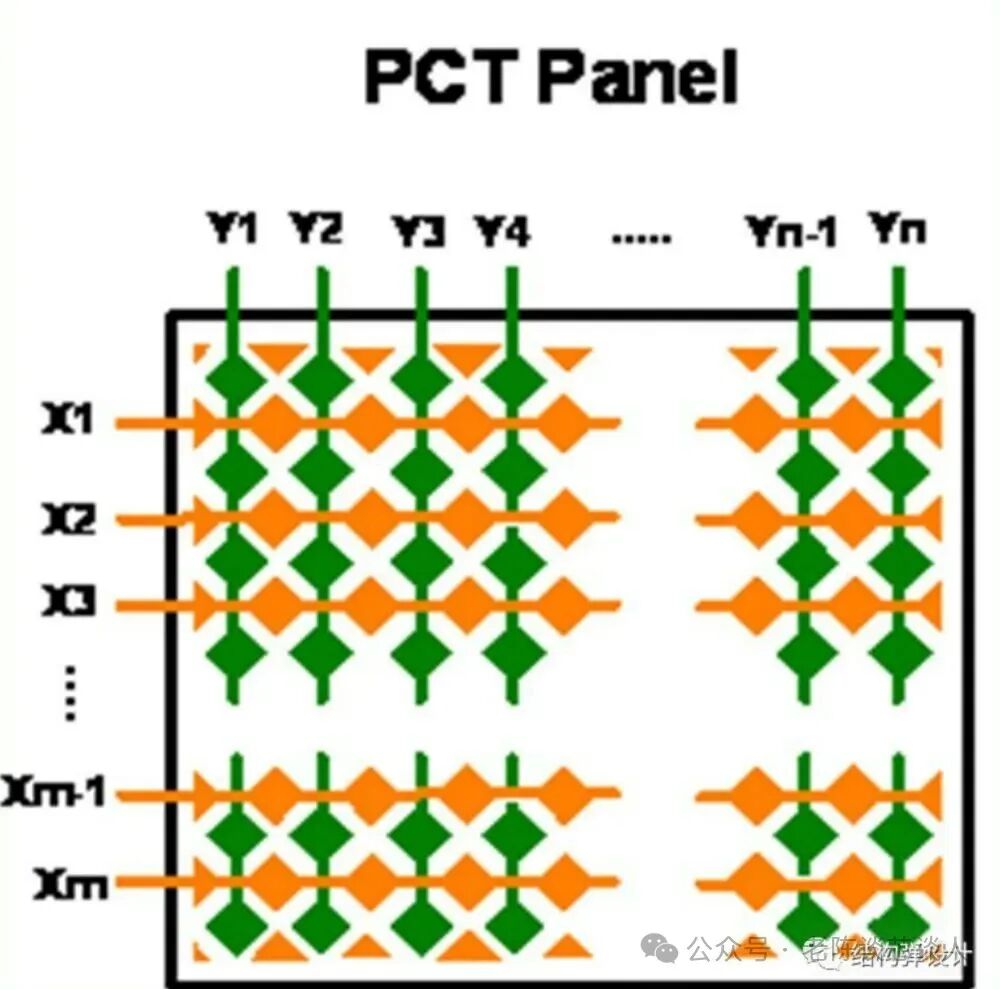

When a user touches the screen, due to the human body’s electric field, a coupling capacitance is formed between the finger and the conductor layer. The four edge electrodes generate current that flows to the touch point, and the strength of the current is proportional to the distance between the finger and the electrode. A significant issue with this principle is that it suffers from severe drift; any external interference can cause the touch screen to malfunction. I have not seen this principle applied in any field.Projected Capacitive Touch ScreenWorking PrincipleBasic Principle: The touch screen uses multiple layers of ITO to form a matrix distribution, intersecting along the X and Y axes, functioning as a capacitive matrix. When a finger touches the screen, the change in capacitance at the touch point can be detected through scanning the X and Y axes, allowing the calculation of the finger’s position. Based on this architecture, projected capacitive touch can achieve multi-touch operations.

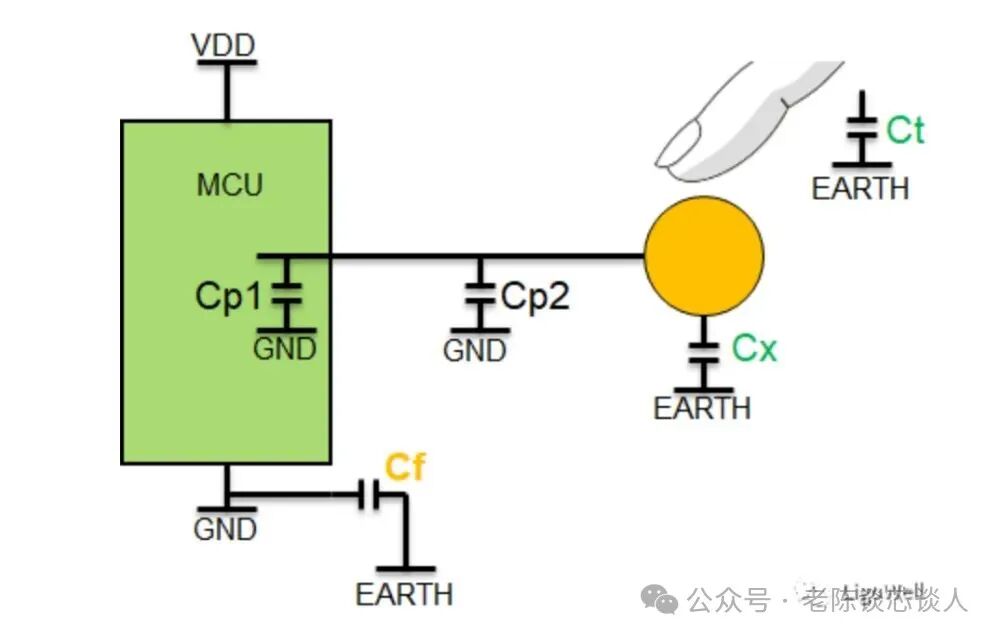

There are two types of projected capacitive touch: the self-capacitance principle and the mutual capacitance principle. These two principles are widely used in consumer electronics, industrial applications, and automotive fields.Self-Capacitance Principle

There are two types of projected capacitive touch: the self-capacitance principle and the mutual capacitance principle. These two principles are widely used in consumer electronics, industrial applications, and automotive fields.Self-Capacitance Principle

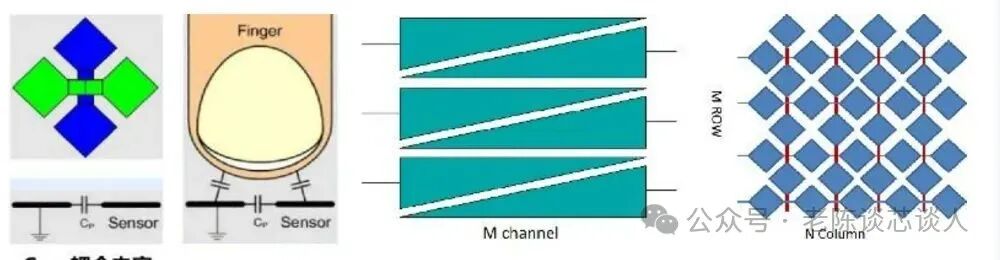

Measures the capacitance change between a single electrode and ground.The scanning method for capacitance is done row by row, where all channels serve as both sensing channels and driving signal channels. By comparing the capacitance changes before and after touch, the X and Y coordinates can be determined, which are then combined to form the touch point coordinates.Mutual Capacitance Principle

Measures the capacitance change between a single electrode and ground.The scanning method for capacitance is done row by row, where all channels serve as both sensing channels and driving signal channels. By comparing the capacitance changes before and after touch, the X and Y coordinates can be determined, which are then combined to form the touch point coordinates.Mutual Capacitance Principle

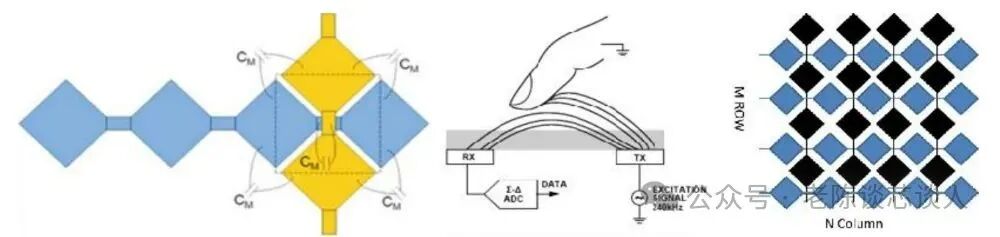

Measures the coupling capacitance change between row electrodes and column electrodes.Mutual capacitance divides the X and Y direction channels into driving signal channels and sensing signal channels. The driving signal is sent row by row, and when the first row driving signal is emitted, the sensing signal channels scan row by row to determine if there is a change in capacitance. When touched, it is equivalent to connecting a capacitor in series, thus reducing the capacitance..Embedded TPCurrently, screen manufacturers are promotingembedded TP, which mainly includes the In-cell and On-cell processes. The difference between In-cell/On-cell and external TP is that the TX/RX is located inside the polarizer, meaning the TP lines are made in different positions within the LCM..In-cell:The touch lines are directly made between the front and back conductive glass of the panel (Cell), referred to as In-cell. Currently, there are several technical structures:

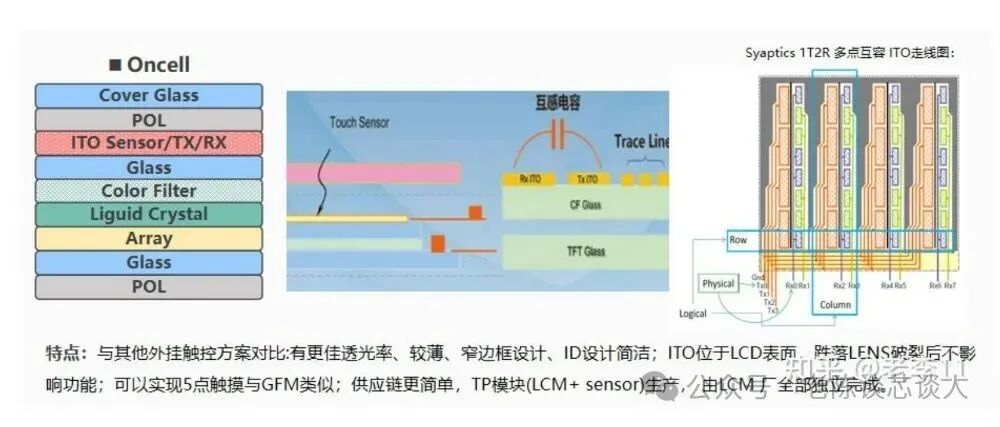

Measures the coupling capacitance change between row electrodes and column electrodes.Mutual capacitance divides the X and Y direction channels into driving signal channels and sensing signal channels. The driving signal is sent row by row, and when the first row driving signal is emitted, the sensing signal channels scan row by row to determine if there is a change in capacitance. When touched, it is equivalent to connecting a capacitor in series, thus reducing the capacitance..Embedded TPCurrently, screen manufacturers are promotingembedded TP, which mainly includes the In-cell and On-cell processes. The difference between In-cell/On-cell and external TP is that the TX/RX is located inside the polarizer, meaning the TP lines are made in different positions within the LCM..In-cell:The touch lines are directly made between the front and back conductive glass of the panel (Cell), referred to as In-cell. Currently, there are several technical structures: On-cell:The sensor lines are coated on the surface of the front conductive glass (CF) of the LCD, referred to as On-cell.

On-cell:The sensor lines are coated on the surface of the front conductive glass (CF) of the LCD, referred to as On-cell. Touch Performance Touch performance GFF > In-cell > GFM > On-cell > GF

Touch Performance Touch performance GFF > In-cell > GFM > On-cell > GF Conclusion My personal level is limited, so I can only do some basic education work, discussing physical structures and terminology explanations. The details of parameter advantages and disadvantages need to be known by professional engineers. If you are that professional technical engineer, please contact me to learn from you, and I will write articles for your company and products for free. TP chips are still dominated by foreign brands, while domestic brands like Goodix have a high market share. Large sizes and strong anti-interference capabilities are still dominated by Europe and the United States. Old Chen has a learning heart and is dedicated to the industry.Old Chen’s discussion group QR code is valid for 7 days. If the QR code expires, please message Old Chen.

Conclusion My personal level is limited, so I can only do some basic education work, discussing physical structures and terminology explanations. The details of parameter advantages and disadvantages need to be known by professional engineers. If you are that professional technical engineer, please contact me to learn from you, and I will write articles for your company and products for free. TP chips are still dominated by foreign brands, while domestic brands like Goodix have a high market share. Large sizes and strong anti-interference capabilities are still dominated by Europe and the United States. Old Chen has a learning heart and is dedicated to the industry.Old Chen’s discussion group QR code is valid for 7 days. If the QR code expires, please message Old Chen.

10.1-inch TFT-LCD dedicated display control chip3.5-inch TFT-LCD display chipTFT-LCD TCON working principleTFT-LCD screen disassembly analysis principleGoodix capacitive touch selection tableThe past and present of TFT-LCD screen interface protocolsMCU track partners, how are you?

10.1-inch TFT-LCD dedicated display control chip3.5-inch TFT-LCD display chipTFT-LCD TCON working principleTFT-LCD screen disassembly analysis principleGoodix capacitive touch selection tableThe past and present of TFT-LCD screen interface protocolsMCU track partners, how are you?