Before the advent of projectors, we primarily used slide projectors. In fact, modern projectors are also a special form of slide projectors. Research by scholars indicates that the development of projectors, animation, and films is interconnected.

The earliest light and shadow technology began in the seventeenth century with a Jesuit named Athanasius Kircher, who invented the “magic lantern,” which later became a toy and is now known as a projector. Initially, this technology was mainly used for entertainment, utilizing the principles of light and shadow to tell stories on a screen, somewhat similar to the shadow puppetry of the Tang Dynasty. However, with the development of light and shadow technology, projectors became separate from films and animations.

Origin of the Projector——CRT Projection Technology

The history of CRT projectors can be traced back to the 1950s, when they were mainly used in business aircraft for playing video tapes. By the 1980s, the rapid development of personal computers increased the market demand for text and data presentation, prompting significant advancements in CRT projection technology. The application fields of projection technology began to permeate conference rooms, classrooms, and theaters. In the late 1980s, with the widespread use of computer workstations and graphic processing software, graphic projectors capable of projecting high-resolution graphics and animations emerged. The first LCD projector was introduced in 1989, ending the dominance of CRT technology in the projector market. In 1994, the home projector market began to emerge, with CRT projectors being more mature compared to the then-existing LCD projector technology, thus entering the high-end home theater market. However, with the introduction of 3LCD technology in 1996 and the launch of the first DLP projector, CRT projection technology began to decline and quickly faded from public view.

LCD Projection Technology

When it comes to LCD projection technology, we must mention Epson. The liquid crystal chip, which is the core of liquid crystal projectors, is the heart of the entire projection system. One of Epson’s most important contributions to the development of liquid crystal projectors is the successful development of the world’s first LCD projection panel chip, leading to the production of the world’s first LCD projector, VJP-2000, in 1989, thus opening a new era for LCD projectors.

Through continuous technological and product advancements, liquid crystal projection has maintained its leading position in global digital projector technology. In comparison to the emerging DLP and LCOS technologies, LCD holds a market share of over 55%.

Classification of LCD Projection Technology

During the technological evolution of LCD projectors, various types of technology have emerged. In addition to the now dominant three-panel high-temperature polysilicon (HTPS) technology, single-panel technology and liquid crystal light valve projectors have also appeared.

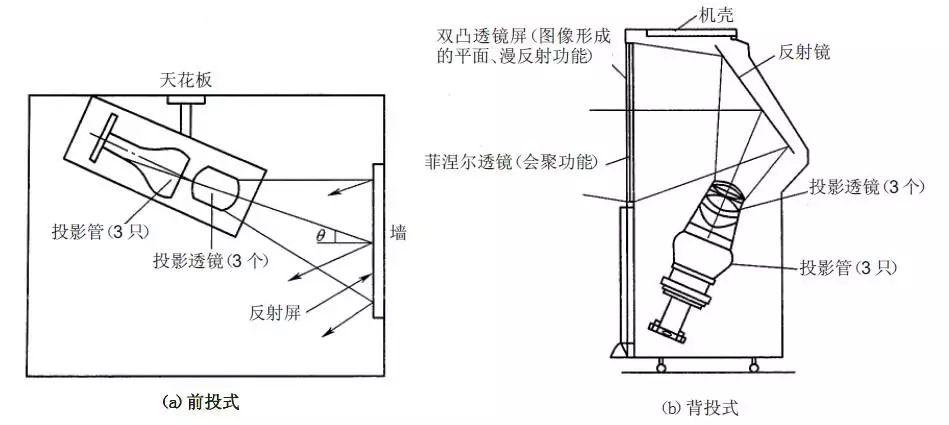

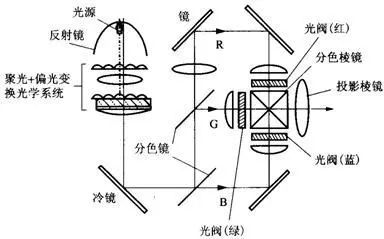

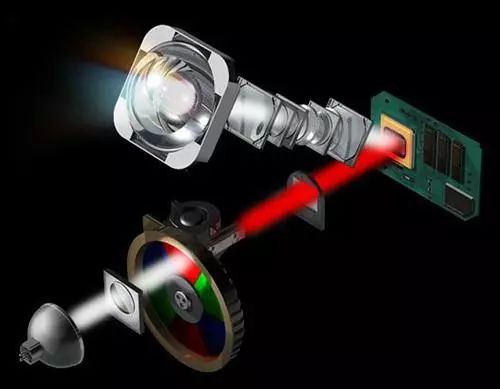

The working principle of single-panel liquid crystal projectors is shown in the figure:

Single-panel liquid crystal projectors use ordinary small-screen liquid crystal display panels as the core chip, along with necessary additional equipment to form a complete working light path. The lens system provides a large-size realistic image, showcasing impactful visual effects. In terms of light paths, this product is constrained by the large chip area, making it difficult to reduce its size, and the overall light efficiency utilization of the light path is very low, with the internal optical and mechanical components’ craftsmanship structure precise to 0.1mm. The selection of major optical components, such as projection bulbs, reflective bowls, mirrors, projection lenses, focus lenses, and Fresnel lenses, has a mature industrial chain that can provide a good product experience.

Liquid crystal light valve projectors are a historical technological form. They essentially utilize the optical switching effect of liquid crystals to improve the imaging effect of CRT projectors.

Liquid crystal light valve projectors use CRT tubes and liquid crystal light valves as imaging devices. They were created to resolve the contradiction between image resolution and brightness in CRT projectors. Generally, a light valve consists of three main parts: a photoelectric converter, a mirror, and a light modulator, acting as a controllable switch. The light signal output from the CRT illuminates the photoelectric converter, converting the light signal into a continuously varying electrical signal. An external light source generates a strong light beam, which is projected onto the liquid crystal light valve, reflected by the internal mirror, and through the light modulator, the polarized filter processes the light valve’s projected light, combining it with the CRT signal to project onto the screen and form an image.

3LCD Projection Technology

3LCD projection technology is the mainstream technology for liquid crystal projectors. Its market share occupies the vast majority of the LCD projector market, having become a de facto standard in the industry.

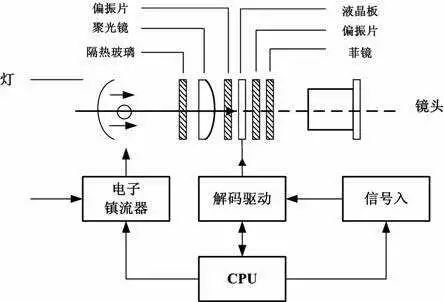

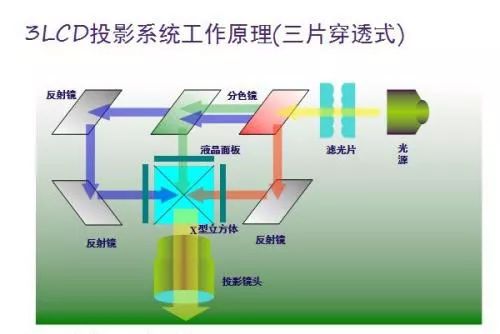

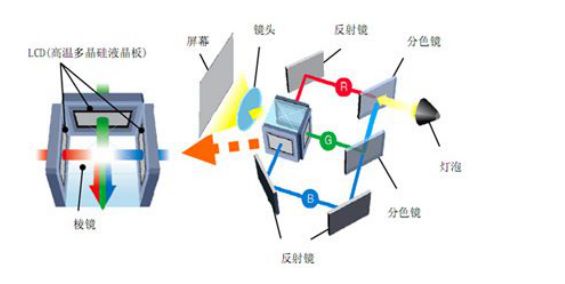

The optical path principle of three-panel liquid crystal projectors involves light emitted from a high-brightness, high-color-temperature metal halide lamp (UHE) being reflected by a parabolic lamp bowl to form parallel light rays, entering the first lens array (unit condensing lens group), then passing through the second lens array (polarized light conversion lens group) to improve the utilization of polarized light. After passing through the splitting optical path, three primary color beams are formed, entering the R, G, and B liquid crystal panels, respectively. Then, a combined prism integrates the three color lights, and the projection lens projects the synthesized image onto the screen.

During this projection process, various optical devices, liquid crystal panel chips, and lamp light sources each play their roles. The light sources generally used include metal halide lamps, UHP (Ultra-High Performance) lamps, and UHE lamps. Metal halide lamps are cost-effective and cheap but have the drawback of generating a lot of heat and having a short half-life. The half-life refers to the time it takes for the lamp’s brightness to decrease to half of its design brightness. To overcome the shortcomings of metal halide lamps, such as high heat generation and short half-life, cold light sources emerged, including UHP and UHE metal halide lamps. UHP and UHE lamps generate much less heat compared to metal halide lamps. Additionally, new light sources, including laser sources and LED inorganic light-emitting diodes, have also become focal points for various companies in developing new technologies.

Besides the light sources, the role of a series of optical devices should not be underestimated. The projection process requires a planar uniform parallel three-primary-color line polarized light source. The light emitted by ordinary bulbs is white spherical circular polarized light. Through a series of adjustments using lenses, Fresnel lenses, and filters, the light emitted by the bulb can become a source of light that meets the projection needs of projectors.

In the imaging process of liquid crystal projectors, the liquid crystal panel chip is in a core position. In actual work, the liquid crystal panel chip acts as an optical switch. Each independent pixel point controlled by the active matrix can change independently, thus controlling the amount of light projected through the liquid crystal. By controlling the three liquid crystal panels separately, and after the final image synthesis, a richly colored and variably shaded color projection image can be achieved. After being magnified and projected onto the screen through the lens, consumers can enjoy outstanding large-size images akin to those seen in movies.

LCD Projection Technology Chips

The liquid crystal chip is the most critical component of liquid crystal projectors. It is not only an important cost component of liquid crystal projectors but also a crucial component that determines the quality performance and lifespan of the entire product.

LCD stands for Liquid Crystal Display. Liquid crystals have both the fluidity of liquids and the optical anisotropy of crystals, commonly referred to as “liquid crystals.” The working temperature of liquid crystal materials is between -55 and 77°C. The intermolecular forces of liquid crystals are weak, and under the influence of an electric field, the arrangement of molecules changes, leading to changes in the transmittance and reflectance of liquid crystals, known as the electro-optical effect of liquid crystals. In liquid crystal display technology, this special property of materials is used to create switches that control the passage of light, thus achieving imaging effects.

The liquid crystal display panel is formed by filling liquid crystal material between two glass substrates, and attaching polarizers, scanning circuits, and thin-film transistors (TFT) to the surface of the glass substrates. When a scanning voltage is applied to the row electrode of a certain pixel, the thin-film transistor (TFT) turns on, allowing that liquid crystal pixel to transmit light. The liquid crystal units between the glass substrates form individual light switches that control the amount of light passing through the liquid crystal, displaying variations in color and brightness.

In actual product development, the liquid crystal panel chips used in projectors must withstand the enormous energy (mainly heat) emitted by the bulbs behind them. This determines that the liquid crystals used in liquid crystal projectors differ from those used in ordinary liquid crystal displays and liquid crystal TVs. Currently, the main technology used in liquid crystal projectors is called “high-temperature polysilicon liquid crystal panel (HTPS).”

HTPS stands for High Temperature Poly-Silicon, which translates to “高温多晶矽” in Chinese, commonly referred to as high-temperature glass. It is a branch of the liquid crystal display family and belongs to the active matrix (TFT) type LCD (Active Matrix LCD).

The most significant feature of HTPS liquid crystal chips is their stability during continuous high-temperature operation, providing a fundamental technical platform for improving the lifespan and brightness of projector products. Additionally, this technology also features accurate color reproduction and comfortable visual perception. Currently, this technology has become a crucial component in the global digital projection field.

Development Bottlenecks and Advances in LCD Projection Technology

As the core of liquid crystal projection technology, the progress of LCD chips has always been a barometer for the development of the liquid crystal projection industry.

In the early LCD projectors, issues of lifespan, brightness, and size became the main constraints on product advancement. Because the core material of liquid crystal projectors is polymer liquid crystal material, its aging effect at high temperatures is evident. Additionally, the glass substrate of the liquid crystal panel may also undergo optical performance changes due to prolonged high-temperature baking. These two factors resulted in early liquid crystal projectors, especially in the last century, having chip lifespans of less than 5000 hours, significantly increasing consumers’ actual usage costs.

In early liquid crystal projector products, how to achieve more refined TFT thin-film transistors and their control circuits became the biggest challenge for miniaturizing and increasing the aperture ratio of liquid crystal projection chips. The entire optical machine system with a three-panel design cannot achieve product miniaturization if the chip size cannot be reduced. Once the chip shrinks, if the on-chip control circuit components cannot be significantly simplified and reduced, it leads to a decrease in the proportion of the chip area available for optical switching (aperture ratio), resulting in reduced light utilization and brightness.

Furthermore, another characteristic of liquid crystal displays is the tailing of images and the lack of true black levels in black images. The deflection of liquid crystal molecules under the influence of electromagnetic fields requires some time, and it also has hysteresis, leading to the occurrence of trailing phenomena in liquid crystal display products. It is challenging to achieve 100% blockage of light transmission with liquid crystal projection chips using transmission light paths, resulting in black images not being truly black, significantly affecting the overall contrast and detail presentation in dark areas of the image.

In recent years, with the continuous development of liquid crystal projectors, the above issues have been well addressed. In the advancement of liquid crystal projector chip technology, pursuing smaller sizes, higher aperture ratios, longer lifespans, higher gray-scale control precision, and higher refresh rates is the primary focus. Currently, the most advanced chips can achieve 1080p pixels under one inch, over 50% aperture ratio, more than 12-bit fine control, and ultra-high refresh rates of 120Hz. These significant advancements have propelled LCD liquid projectors into a new stage of development.

DLP Projection Technology

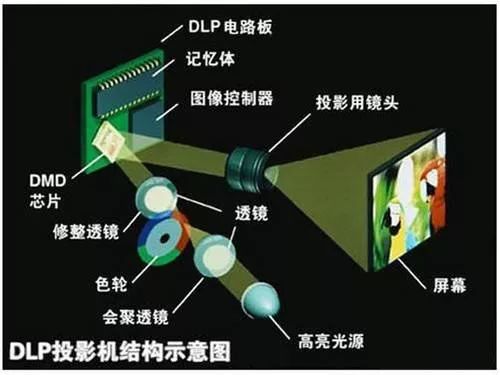

DLP is a truly all-digital reflective projection technology developed by Texas Instruments based on its research of Digital Micromirror Devices (DMD). DMD consists of millions of micro mirrors, each measuring 10.8×10.8 microns, smaller than the cross-section of a hair. Each micro mirror can reflect light in two directions; when the digital signal is in the “ON” state, the micro mirror rotates +12 degrees, and when the signal is “OFF,” it rotates -12 degrees.

As the micro mirrors rapidly rotate back and forth, they create grayscale, and when paired with one or three DMD chips, vivid color display effects can be achieved. A DLP projection system equipped with a single DMD chip is called a “single-chip DLP projection system,” which can generate at least 16.7 million colors after filtering through a color wheel; a three-chip DLPCinema projection system can generate 35 million colors. Currently, DLP has introduced the latest “extreme color” technology, which can even create over 200 million colors.

Based on the number of DMD micro mirrors included in DLP projectors, they are classified into single-chip DLP projectors, two-chip DLP projectors, and three-chip DLP projectors.

Many DLP projectors available in the market are single-chip, mainly used in various portable projection products. These single-chip DLP projectors typically have a body size smaller than that of an A4 sheet and are designed for mobile executives. The casing is generally an elegant magnesium alloy shell. Despite their compact size, these single-chip DLP projectors are powerful, offering high clarity, uniform images, and sharp colors. With such a projector, users can easily pack it into their briefcase and head out to showcase vibrant, clear images to clients at any time.

Compared to single-chip DLP projectors, two-chip DLP projectors use an additional DMD chip, where one chip controls red light while the other chip controls the reflection of blue and green light. Like single-chip DLP projectors, they use a high-speed rotating color wheel to produce full-color projection images, mainly used in large display walls, suitable for large entertainment venues or users requiring large screens.

Three-chip DLP projectors have three DMD chips, each reflecting one of the primary colors, eliminating the need for a color wheel for filtering. Projectors made with three DMD chips can achieve brightness levels of up to 12,000 ANSI lumens. They discard traditional notions of convergence, allowing for convenient zoom adjustments; however, their resolution is not high, and without compression, the resolution can only reach standards of 1280×1024, making them often used in scenarios with very high brightness requirements.

DLP Projection Technology Features

As an advanced digital technology, DLP features high clarity, high reliability, high dust resistance, high contrast, high response speed, high portability, and high cost-performance ratio:

High Clarity

The core of DLP technology is the digital micromirror system composed of thousands of mirrors, with distances between each mirror of less than 1 micron, allowing for extreme reduction of the distance between projection image pixels, generating seamless digital images that maintain good sharpness at any size without the lattice (mosaic phenomenon) caused by other technologies. This is why images projected using DLP technology always remain crystal clear.

High Reliability

DLP is a digital technology, and the advantage of digital projection technology is that it can completely and faithfully reproduce images without being affected by factors such as temperature, humidity, or vibration; the lifespan of DLP chips exceeds 100,000 hours, ensuring that the images do not fade.

High Dust Resistance

For educational projectors, which occupy over 45% of the domestic market share, one of the most critical additional features is dust resistance. Projectors manufactured using DLP technology can adopt a fully enclosed optical design, protecting the DLP chip and other components, making it difficult for dust to reach the core of the optical path, thus ensuring that image quality remains unaffected by dust.

High Contrast

When watching films, the three-dimensionality of the image is crucial. The human visual system relies on contrast to distinguish object edges; therefore, images with high contrast appear sharper. When contrast is low, dark areas appear blurred, and the image looks flat and lacks realism. For text materials commonly used in education (files in PowerPoint, Excel, Word formats), the high native contrast of DLP technology can clearly and sharply present text, which is unmatched by other technologies that emphasize dynamic contrast, as projectors need high “native” contrast when presenting text content.

High Response Speed

DLP technology has a fast switching speed of only a few microseconds, which is a thousand times faster than the response speed of liquid crystal panels measured in milliseconds. Because of this fast response speed, even high-speed dynamic images such as racing or ball games do not exhibit trailing effects, presenting the clearest and most realistic images.

High Portability

Single-chip DLP projectors used in education, business, and consumer markets only require one panel, while all other projection technologies require three. Therefore, DLP projection systems can be made very small and lightweight, leaving ample space for innovative designs. Currently, many manufacturers, including Samsung, Mitsubishi, and Toshiba, have launched DLP pocket projectors weighing less than one pound, marking a new era of projector applications.

LCOS Projection Technology

LCOS projection technology is the latest projection technology developed after 2000, which is a new type of reflective projection technology. Compared to transmissive LCD and DLP, LCOS has advantages such as high light efficiency, small size, high aperture ratio, and mature manufacturing technology, allowing for easy achievement of high resolution and rich color representation. LCOS technology has significant advantages in large-screen display applications in the future, as it does not have a crystal mode and has an open architecture with low-cost potential.

In recent years, many new technologies have emerged in the LCD industry, among which the most popular technology, LCOS, has the greatest advantage of high resolution, which is unmatched by other technologies in the application of portable information devices.

In fact, the biggest difference between LCOS and other projection technologies lies in the optical path design for controlling light decomposition and merging, specifically how to adjust the RGB components based on the pixel information in the image (the modulation process). LCD and DLP use light transmission modes to adjust RGB components, resulting in significant light loss. In contrast, LCOS uses reflective technology, which minimizes light loss! Furthermore, in terms of design, the aperture ratio of LCOS liquid crystal panels is much larger than the previous two types, which naturally reduces power consumption.

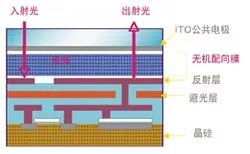

The structure of LCOS involves growing liquid crystals on a single crystal silicon wafer, utilizing semiconductor integration to create a driving panel (also known as CMOS-LCD). After polishing, an aluminum film electrode is deposited on it to serve as a reflector, forming a CMOS active matrix substrate. The CMOS substrate is then bonded with a glass substrate containing ITO transparent electrodes, liquid crystals are injected, and the assembly is sealed. The pixel electrodes also serve as reflective mirrors, and the pixel sizes can be made very small, approximately 7 to 20 microns, with an aperture ratio as high as 96%. For a million-pixel high-resolution substrate, the size is still less than one inch.

Principle of LCOS Projection Display Technology

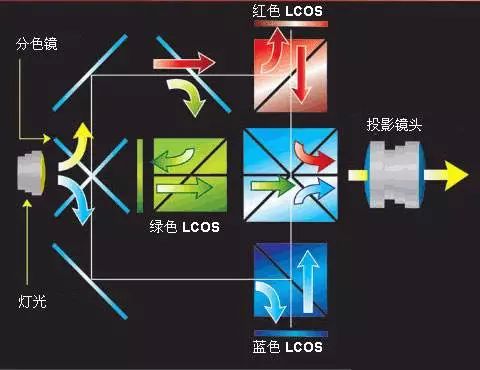

The basic principle of LCOS projectors is similar to that of LCD projectors, except that LCOS projectors use LCOS panels to modulate the light signals emitted by the light source intended for projection onto the screen. When light hits the LCOS chip, its reflected light is modulated by the voltage between the CMOS electrodes and ITO electrodes, thus the LCOS chip is essentially a light modulating device. Utilizing this property, the image or data information is converted into voltages for the CMOS electrode array, achieving imaging of reflected light. The light from the light source is polarized and transmitted to a prism where it is split into red, green, and blue light, which is projected onto the LCOS chip for image modulation. The modulated light is then combined through a light convergence system and enters the projection lens to illuminate the screen for imaging.

LCOS panels are based on CMOS chips as circuit substrates, so light cannot pass directly through them. Their design of the light splitting and combining system differs somewhat from that of LCD projectors. Typically, a polarized beam splitter (PBS) is used in the light splitting and combining system to separate the incident light beam hitting the LCOS panel from the reflected light beam.

The light emitted by the light source is split into red, green, and blue light after passing through a Dichroic Mirror (two-color mirror, i.e., dichroic filter). These three colors then pass through their respective PBS, reflecting S-polarized light into the LCOS panel. When the liquid crystal is in the bright state, the S-polarized light changes to P-polarized light, and finally, the two-color prism (Dichroic Prism, i.e., convergence lens) combines the modulated three polarized lights, projecting them onto the screen to form an image.

LCOS Debugging Principle

The image modulation principle of LCOS projectors is fundamentally the same as that of LCD, also utilizing light modulation to control the projected display image. The incident light is polarized after being split, passing through the incident polarizer (PBS), converting the incident light into S-polarized light, which is reflected and modulated by the LCOS panel. If the liquid crystal is modulated by an external signal and is in the bright state, the S-light will change to P-light, and after passing through the prism, the most light will be projected to the convergence lens for imaging. In the dark level display state, the S-light remains S-light after modulation, and no light is transmitted through the prism to the convergence lens, resulting in a dark image display. Therefore, the amount of light output to the convergence lens is determined by the external signal modulation of each pixel.

Comparison of Different Projection Technologies

Comparison of parameters for CRT, LCD, DLP, and LCOS projection chips

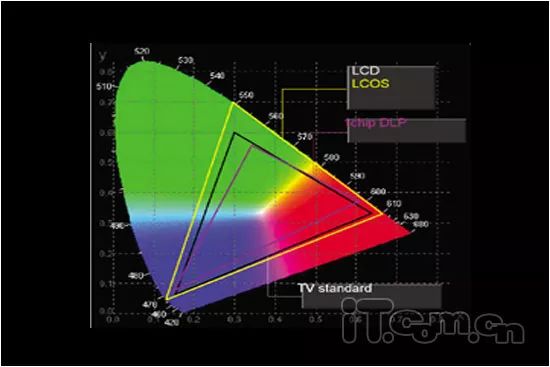

CRT, LCD, DLP, and LCOS projection chips each have their technical characteristics. Using the color gamut of CRT projection as a standard, it is evident from the following chart that the color gamut of LCD and its derivative LCOS projection chips is very broad, far exceeding the range that CRT and DLP chips can represent.

For applications sensitive to color gamut range, three-panel LCD and LCOS projection chips are the preferred choice. However, due to the integration of a large number of TFT (Thin Film Transistor) on the chip, it is inevitable that some TFTs may be damaged or fail during the manufacturing process, remaining in either the on or off state, which inevitably leads to bright or dark spots in the image. Moreover, this damaged TFT continues to increase with prolonged usage time. This is currently the Achilles’ heel of LCD and LCOS chips. DLP’s characteristics are high contrast and high reliability.

Performance Comparison of CRT, LCD, DLP, and LCOS Projection Elements:

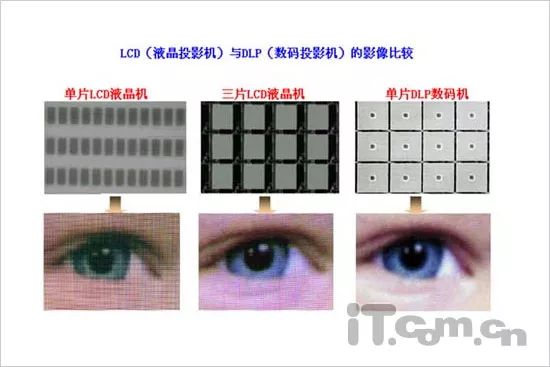

Comparison of Image Effects between LCD and DLP Projection

Source: Sensor Technology

END

Hot Articles (Swipe up to read)

Paper Recommendation | Ding Zhengdao: Research on the Car Headway Mixed Distribution Model Based on YOLOv5+DeepSORT Detection Data

Paper Recommendation | Zhan Keyi: Research on the Design of the Aerodynamic Instability Detection Pipeline for Aircraft Engines

Paper Recommendation | Liu Hao: Efficient Human Pose Estimation Based on Diverse Convolution Units

Paper Recommendation | Wang Hong: Application and Development of Aviation Testing Technology for Intelligent Assurance

Paper Recommendation | Zhao Xiaoping: Small Sample Gearbox Fault Diagnosis Method Based on Transfer Learning

Paper Recommendation | Zhu Xinyun: Progress in Flight Data Analysis and Application Research for PHM

Paper Recommendation | Wan Yuhong: Research Progress of Terahertz Time-Domain Spectroscopy Technology in Coating Detection

Paper Recommendation | He Yunze: Development and Application Review of Image-Based Multimodal Perception and Multi-Source Fusion Technology

Paper Recommendation | Ou Zhengyu: Current Status and Prospects of Underground Pipeline Detection Technology

Paper Recommendation | Ren Liping: Feature Selection for Multidimensional Health Monitoring Fusion Data

Paper Recommendation | Chai Yongsheng: Experimental Research on Strength Monitoring Technology of Glass Fiber Reinforced Plastic Based on Infrared Spectral Analysis

Paper Recommendation | Liu Zenghua: Research Progress on Defect Detection of Electromagnetic Ultrasound Level Shear Waves

Paper Recommendation | Yu Haoyan: Review of Microwave Nondestructive Testing Technology for Non-Metallic Pipelines

Paper Recommendation | Huang Songling: Review of Nondestructive Testing and Online Monitoring Technology for Defects in Aircraft Engine Blades

Paper Recommendation | Xiong Pengwen: Robot Interaction Object Classification Based on New Multimodal Tactile Sensors

2022 Collection of Excellent Papers in Computer and Automation Technology

2022 Collection of Excellent Papers in Aerospace

Paper Recommendation | Liu Jia: Construction of a High-Fidelity Visual-Tactile Augmented Reality System

Paper Recommendation | Feng Lihang: Wheel-Legged Detection System for Soft Soil on Planetary Rovers: II – Perception Wheel

Paper Recommendation | Feng Lihang: Concept Design of Wheel-Legged Detection System for Soft Soil on Planetary Rovers: I – Concept Design

Paper Recommendation | Li Honghao: Application of Fiber Bragg Grating Force Sensors in Health Care

Paper Recommendation | Liang Qiaokang: Multi-Dimensional Force Sensors for Robots

Paper Recommendation | Xu Hongning: Design and Implementation of a Face Recognition Algorithm Testing Platform Based on Hadoop and RabbitMQ

Paper Recommendation | Pan Kuangming: Reliability Analysis and Testing of a New Type of 24-Pulse TRU Based on Pulse Doubling

Paper Recommendation | An Xin: Robust License Plate Recognition Method Based on Deformable Convolutions and Adaptive 2D Position Encoding

Paper Recommendation | Qi Jinping: Overview and Prospect of Remaining Useful Life Prediction Methods for Small Sample Complex Systems Driven by Data

Article Recommendation | Chen Xuanwen: Research on Model-Driven Component Libraries for Flight Control Software Factories

Article Recommendation | Du Guaning: Technology for Measuring the Input End Position of Aircraft Control Systems Based on Vision

Article Recommendation | Ju Wenying: Numerical Study of Gas Intrusion in Multi-Boundary Disc Chambers Downstream of Axial Turbine Rotors

Article Recommendation | Cui Linwei: Research on SLAM for Intelligent Wheelchairs Based on MEMS Laser Radar

Article Recommendation | Zhang Zhen: Application of Industrial CT in the Aviation Industry

Article Recommendation | Zhu Chen: Research on Improved Algorithms for SLAM Loop Detection Based on Binocular Cameras

Article Recommendation | Sun Yu: Research on the Application of New Fiber Sensors in Pipeline Leak Monitoring

Article Recommendation | Xiong Yunong: A Visual Measurement Technology Based on Target Recognition and Positioning Algorithms

Article Recommendation | Zhou Yitian: Bearing Fault Diagnosis Model Based on Feature Expansion CapsNet

Article Recommendation | Wang Hong: Embedded Online Monitoring Technology for Foreign Avionics Systems

Article Recommendation | Wang Bin: Three-Dimensional Measurement of Icing Ice Shapes Based on Linear Structured Light Scanning

Article Recommendation | Jia Funian: Design and Verification of High-Altitude Inlet Devices for Turbojet Engines

Article Recommendation | Yan Bo: Research on the Oxygen Partial Pressure of Al2O3 High-Temperature Insulation Films Based on Dual Ion Beam Sputtering