When it comes to control systems, many people seem to speak with great confidence, but when delving deeper, they become speechless about the definitions of controllers, PLCs, DCS, and FCS. After a brief introduction to the basic concepts, it feels like the conversation misses the point.

Today, let’s discuss what DCS is.

First, we can clarify that DCS is a historically significant form of control system. Control systems are divided into upper and lower machines, where the upper machine focuses on GUI (Graphical User Interface) and the lower machine focuses on algorithms.

Some friends may ask, what is configuration?

Configuration is essentially the process of building the software and hardware environment of a system. Simply put, configuration is about combining existing simple functions to create more complex functionalities.

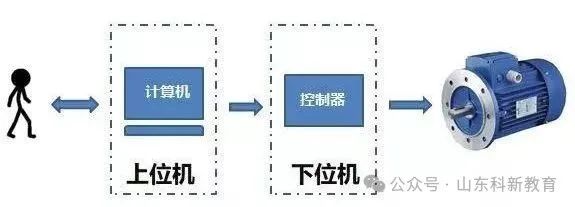

What are upper and lower machines?

For example, imagine you are developing a control system. The first step is to tell the computer what you want to do, then the computer notifies the controller, and finally, the controller tells the actuator how to proceed. Here, I am only communicating with the computer, which is the upper machine, while the controller that receives the computer’s instructions is the lower machine.

In essence, both the computer and the controller are computers, but their external forms, application environments, and programming methods differ, leading to the need for understandable naming conventions. The upper machine interacts with humans, hence it emphasizes GUI, featuring peripherals like monitors or touch screens, mice, and keyboards. The lower machine interacts with actuators, thus it emphasizes algorithms, requiring users to write executable programs to download to the lower machine. The instructions from the upper machine trigger the lower machine’s program execution, making the lower machine akin to a black box where users cannot intuitively see every process and step during execution, and can only analyze the results—whether they are correct, accurate, or satisfactory.

How do configuration and upper/lower machines relate to DCS?

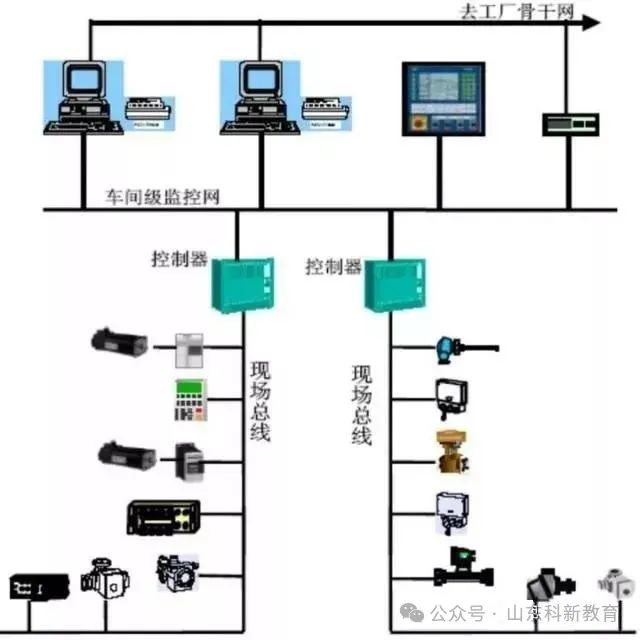

Distributed Control System –> DCS, because DCS is also a control system that adheres to the basic form of control systems, it also has upper and lower machines and requires software and hardware configuration. “Distributed” refers to the characteristics and differentiation of the DCS control system. Therefore, understanding what DCS is must begin with its distributed nature.

1. The Evolution of DCS It is generally believed that to analyze the characteristics and differentiation of any entity, one must answer two philosophical questions: 1) Where does it come from? 2) Where is it going? Similarly, to understand what DCS and distribution are, we cannot ignore the evolution and development direction of DCS, which we will discuss in relation to the impact of the four industrial revolutions on process industrial control systems to help everyone gain a deeper understanding of DCS. In the first industrial revolution, the steam era, automatic control could only accomplish very simple functions. Based on physical point calculations, it was merely the current DI and DO, capable of performing functions such as starting and stopping a locomotive. At most, it could achieve forward and reverse rotation and simple speed control with the involvement of some peripheral mechanical devices. The well-known Watt is recognized as the inventor of the steam engine, but the steam engine predates Watt’s birth by a significant margin, and the earliest DCS was closely related to steam engines. In the second industrial revolution, the electrification era, the popularity of electronic devices such as relays allowed for on-site control of large equipment. Compared to before, the improvement was that for particularly large equipment, local control eliminated the need to climb onto the equipment for start/stop operations. Later, people found this cumbersome because moving from one device to another for operations was also inconvenient. Therefore, all the control buttons were placed in one room, equipped with simple indicator lights, and operators monitored a large number of indicator lights on the display, ready to press a row of start/stop buttons on the control panel. The third industrial revolution, the information age, saw the development of control systems alongside advancements in electronic computer technology, leading to the formation of mature centralized control systems, which are now referred to as CCR (Central Control Room) or integrated control centers. Why was there a shift to decentralized control later? Because it was found that centralized control could lead to many issues; when points are too centralized and the control scale is too large, if a critical path (module) fails, it could paralyze a large control area. This is a common issue with centralized systems—when one fails, many are affected. Therefore, people considered making the hardware more decentralized, distributing it closer to control areas, increasing operator stations while retaining CCR. Operators still work in the control room, but the entire system operates more stably. Furthermore, to enhance communication efficiency, a new breed known as FCS (Fieldbus Control System) emerged. This means that previously, to communicate, each control group required a dedicated communication role, which became cumbersome and inefficient. Thus, one-to-one communication was eliminated, and everyone communicated through a designated entity, which is the fieldbus.

In the fourth industrial revolution, the Internet of Things (IoT) era, many enhancements were made to make control systems appear more sophisticated, with more decision support and data statistics and analysis. This led to the addition of many functions such as OEE, MES, ERP… With the arrival of the IoT era, a new control system called ICS emerged, focusing on functional systems, modular hardware, and flattened organizational structures.

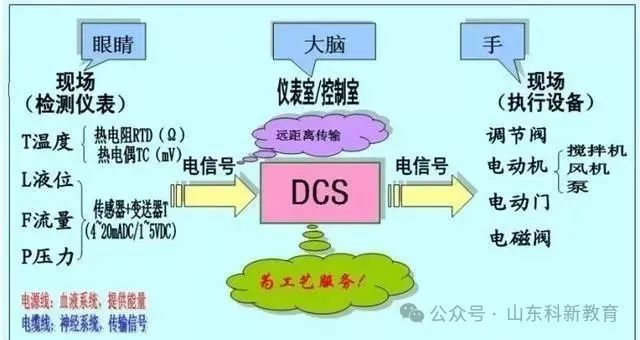

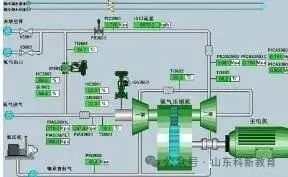

2. The System Composition of DCS Having discussed the evolution of DCS, which may seem abstract, friends may ask what the basic form and composition of DCS is today. The following diagram can intuitively explain what DCS is and what it is used for. For example, due to a certain process requirement, the water tank level must be maintained within a certain range. When the water level fluctuates significantly and exceeds this range, one can choose to manually adjust the control valve on-site or issue instructions via DCS to regulate it. As shown in the diagram below, DCS acts as the brain, responding to the situation observed by the eyes (i.e., signals transmitted from on-site detection instruments, such as a lowering water level) by issuing instructions (e.g., increasing the opening of the inlet valve), and the field execution device receives the instructions and takes appropriate actions (e.g., increasing the opening of the inlet valve to maintain the water level within a certain range).

The examples provided seem to belong to the process industry category. But what about discrete manufacturing industries like automotive? There, another star product, PLC, shines. PLC and DCS play crucial roles in industrial automation control, which is at the core of national industrial development strategies. Both PLC and DCS continuously upgrade and improve across various stages of industrial control, becoming indispensable tools in modern industrial production.

1. Definitions of DCS and PLC

The DCS control system, also known as the distributed control system in the domestic automation industry, is a new type of computer control system developed and evolved from centralized control systems. DCS integrates process control and monitoring into a comprehensive computer system, and with the continuous advancement of communication networks, the DCS system has become a complete system of computer, communication, display, and control technologies, often referred to as the 4C technology system. Its main features include decentralized control, centralized operation, hierarchical management, flexible configuration, and ease of configuration. Nowadays, DCS systems can be widely used in production control and management of industrial installations, with applications in process automation fields such as chemical, power, and metallurgy being quite common. PLC, or Programmable Logic Controller, is an electronic system designed for digital operation in industrial environments. It uses a type of programmable memory to internally store programs, execute logical operations, sequential control, timing, counting, and arithmetic operations according to user instructions, and control various types of machinery or production processes through digital or analog inputs/outputs, making it a core component of industrial control.

2. Differences Between DCS and PLC Controllers

The main difference between DCS and PLC controllers lies in the operation of digital and analog signals. Even though there has been some overlap between the two since the 1980s, there are still distinctions. After the 1980s, PLCs, in addition to logical operations, also incorporated some control loop algorithms, but completing complex operations remained challenging. PLC programming uses ladder diagrams, making analog operations less intuitive and programming cumbersome. However, PLCs excel in rapid logical calculations. DCS, on the other hand, uses functional block encapsulation for analog and logical operations, with clear expression forms for both logical and complex analog operations, although the efficiency of expressing logical operations is relatively lower compared to PLC.

3. Applications of DCS and PLC in Thermal Power Plants

In the field of thermal automation, DCS and PLC are two completely different yet intricately connected concepts. DCS and PLC are products of the combination of computer technology and industrial control technology. The main control system of thermal power plants uses DCS, while PLC is mainly applied in auxiliary workshops of power plants. Both DCS and PLC have operator stations that provide human-machine interaction, rely on computer technology-based controllers for control calculations, exchange data with primary elements and actuators through I/O cards, and possess communication systems referred to as networks. With the continuous expansion of installed capacity in domestic power plants and the advancement of power system reforms, the requirements for control in auxiliary workshops are also increasing. In this context, the integration of DCS systems into auxiliary workshop control has become a trend. The NT6000 DCS, due to its comprehensive technical and economic advantages, has already played and will continue to play an increasingly significant role in auxiliary workshop control.

PLC, widely used in auxiliary workshops, will not exit the stage of thermal automation history. The unprecedented competitive pressure will prompt PLC manufacturers to align more closely with DCS standards in technology and make greater efforts in pricing. The competition between DCS and PLC will ultimately benefit users.

4. Control Processing Capabilities of PLC and DCS

A PLC controller can often handle thousands of I/O points (up to over 8000 I/O). In contrast, a DCS controller typically handles only a few hundred I/O points (not exceeding 500 I/O). From the perspective of a distributed system, centralized control is not allowed; having too many points on a controller is useless in practical applications. DCS developers do not need to develop controllers capable of handling many I/O points; their primary focus is on providing system reliability and flexibility. PLCs, on the other hand, as independent flexible control devices, benefit from higher point capacity, which indicates higher technical standards. As for the overall application level of the control system, that is primarily the responsibility of the engineering company and users, not the core goal of PLC manufacturers. Another indicator of control processing capability is calculation speed; PLCs are generally perceived to be much faster than DCS. New DCS controllers have adopted designs from large PLCs, significantly improving performance in control cycles. For instance, the NT6000 DCS’s T2550 controller can set four different priority tasks, with the minimum calculation cycle set to 10ms, and with high-speed I/O cards, control cycles can reach 15-20ms, while analog calculations are set in other tasks with longer cycles.

5. System Scalability and Compatibility of PLC and DCS

The market is filled with various control products; both DCS and PLC have many manufacturers producing and selling them. For PLC systems, there is generally little or no need for expansion, as PLC systems are usually used for specific devices. Generally speaking, PLCs also have minimal compatibility requirements; for example, sharing resources between two or more systems is challenging for PLCs. Furthermore, PLCs often use dedicated network structures, such as Siemens’ MPI bus network, making it difficult or costly to add an operator station. In the development of DCS, although each manufacturer has its own system, most DCS systems, such as Yokogawa, Honeywell, ABB, etc., have chosen Ethernet as their operational network platform, adopting standard or modified TCP/IP protocols. This provides convenient scalability. In such a network, controllers and computers exist as nodes, allowing for arbitrary addition or reduction of nodes and layout as long as the network reaches the location. Additionally, based on Windows systems, open protocols like OPC and DDE allow for easy communication between systems to achieve resource sharing.

6. Databases of PLC and DCS

DCS generally provides a unified database. In other words, once data exists in the DCS system’s database, it can be referenced in any situation, such as in configuration software, monitoring software, trend graphs, reports, etc. In contrast, PLC systems usually do not have a unified database; configuration software, monitoring software, and even archival software each have their own databases. This is why it is often said that Siemens’ S7 400 only qualifies as DCS from model 414 and above, as the PCS7 system uses a unified database, requiring the controller to be at least S7 414-3 or higher.

7. Time Scheduling of PLC and DCS

PLC programs generally cannot run according to pre-set cyclic periods. A PLC program executes once from start to finish before starting over. (Some new PLCs have improved this, but they still have limitations on the number of task cycles.) In contrast, DCS can set task cycles, such as for fast tasks. For the same sensor sampling, if the pressure sensor’s change time is very short, we can sample with a 200ms task cycle, while for temperature sensors with significant lag time, we can sample with a 2s task cycle. This allows DCS to reasonably schedule the resources of controllers.

8. Network Structures of PLC and DCS

Generally speaking, DCS commonly uses a two-layer network structure, with one layer for process-level networks. Most DCS systems use their own bus protocols, such as Yokogawa’s Modbus, Siemens and ABB’s Profibus, and ABB’s CAN bus, all built on standard serial transmission protocols such as RS232 or RS485. Field I/O modules, especially for analog sampling data (machine code, 213/scanning cycle), are substantial, and there are many environmental interference factors; thus, a network standard with high data throughput and strong anti-interference capability should be adopted. The bus structure based on RS485 asynchronous communication meets the requirements for field communication. The sampled data from I/O is converted by the CPU into integer or real data for transmission in the operational-level network (the second layer network). Therefore, the operational-level network can adopt a moderately high data throughput, fast transmission speed, and ease of connection network standard. Since the operational-level network is generally set up in the control room, the anti-interference requirements are relatively lower, making standard Ethernet the best choice. The TCP/IP protocol is a standard Ethernet protocol, and we generally use a communication speed of 100Mbit/s. The tasks of PLC systems are relatively simple, so the amount of data transmitted is generally not large, leading to common PLC systems having a single-layer network structure. The process-level network and operational-level network are either merged or simplified into internal connections between modules. PLCs rarely or never use Ethernet.

9. Application Scale of PLC and DCS

PLCs are generally applied in small automatic control locations, such as equipment control or a small number of analog controls and interlocks, while large applications are typically DCS. Of course, this concept is not entirely accurate but is quite intuitive; conventionally, systems with more than 600 points are referred to as DCS, while those below this scale are called PLC. Our heat pumps and QCS, along with control systems for horizontal products, are generally referred to as PLC.

10. Market Situation and Development Direction of DCS and PLC

In the field of thermal automation, the main control system of the main plant invariably uses DCS, while PLC is used in auxiliary workshops. The primary reason for this is that early DCS systems were very expensive, leading to the belief that operations in auxiliary workshops could be intermittent, with lower reliability requirements and fewer analog control needs. From a cost-reduction perspective, PLC was often chosen to build control systems. In contrast, the control systems for boilers, turbines, and generators require long-term stable and reliable operation, with a significant proportion of analog signals, making the choice of expensive DCS necessary from a system performance standpoint. Additionally, analyzing the market competition between main plant DCS and auxiliary workshop control systems reveals an interesting phenomenon. Competition for main plant DCS often occurs between different brand suppliers or agents, with intense competition leading to continuous price reductions for DCS. In contrast, competition for auxiliary workshop control systems typically occurs among various engineering companies within the same PLC brand, with lower barriers and more intense competition, yet the price reductions for PLCs are not as pronounced as for DCS. The primary reason is that DCS manufacturers directly participate in competition, continuously lowering equipment manufacturing and project implementation costs under significant market pressure. In contrast, PLC manufacturers do not directly participate in competition, and various engineering companies can only reduce their limited project costs, leaving little room for maneuver. Currently, the price gap between DCS and high-end PLCs is no longer significant, and the continued use of PLCs in auxiliary workshops is a result of market inertia. The PLC and DCS product markets are vibrant and fiercely competitive. Looking at the PLC market, there are over 200 companies producing more than 400 varieties of PLCs, used across various industries such as power, petrochemicals, metallurgy, materials, packaging, papermaking, automotive, and municipal services. From an industry perspective, foreign manufacturers dominate, each holding their respective spheres of influence. The DCS market is similar to PLC, largely dominated by strong foreign players, though several local companies like Hollysys, Supcon, and Xinhua are gradually growing. Due to the high technical content of DCS, many product demands are project-based, making demand for DCS a longer cyclical process, thus the market structure for DCS is unlikely to change significantly in the short term. Of course, due to the irregular pace of industry development, companies focusing on different industries may experience some changes.

In the future development of control systems, we will see the gradual integration of DCS and PLC technologies, which will promote the development of both and various industries.

Source: This article is reprinted from the internet, copyright belongs to the original author. If there are copyright issues, please contact us for deletion. Thank you!

Scan to Follow

WeChat ID|13615417996

Follow the QR code on the left to get free access to

[Siemens Resource Collection]