[PCB Information Network] FPC, also known as Flexible Printed Circuit, has a significantly different PCBA assembly and soldering process compared to rigid circuit boards. Due to the insufficient hardness and flexibility of FPC boards, without using dedicated carriers, it is impossible to complete basic SMT processes such as fixing, transmission, printing, and placement.

1. Pre-treatment of FPC

FPC boards are relatively soft and are generally not vacuum-packed when leaving the factory. They are prone to absorb moisture from the air during transportation and storage, necessitating a pre-baking treatment before SMT placement to slowly force out the moisture. Otherwise, under the high-temperature impact of reflow soldering, the moisture absorbed by the FPC can quickly vaporize into steam, causing delamination, bubbling, and other defects.

The pre-baking conditions are generally a temperature of 80-100°C for 4-8 hours. In special cases, the temperature can be raised above 125°C, but the baking time must be correspondingly shortened. Before baking, a small sample test must be conducted to determine whether the FPC can withstand the set baking temperature, and it is advisable to consult the FPC manufacturer for suitable baking conditions. During baking, the stacking of FPCs should not be too much; 10-20 PNLs are appropriate. Some FPC manufacturers place a paper sheet between each PNL for isolation, and it is necessary to confirm whether this isolation paper can withstand the set baking temperature. If not, it should be removed before baking. The baked FPC should show no significant discoloration, deformation, or warping, and must pass inspection by IPQC before being placed on the line.

2. Production of Dedicated Carriers

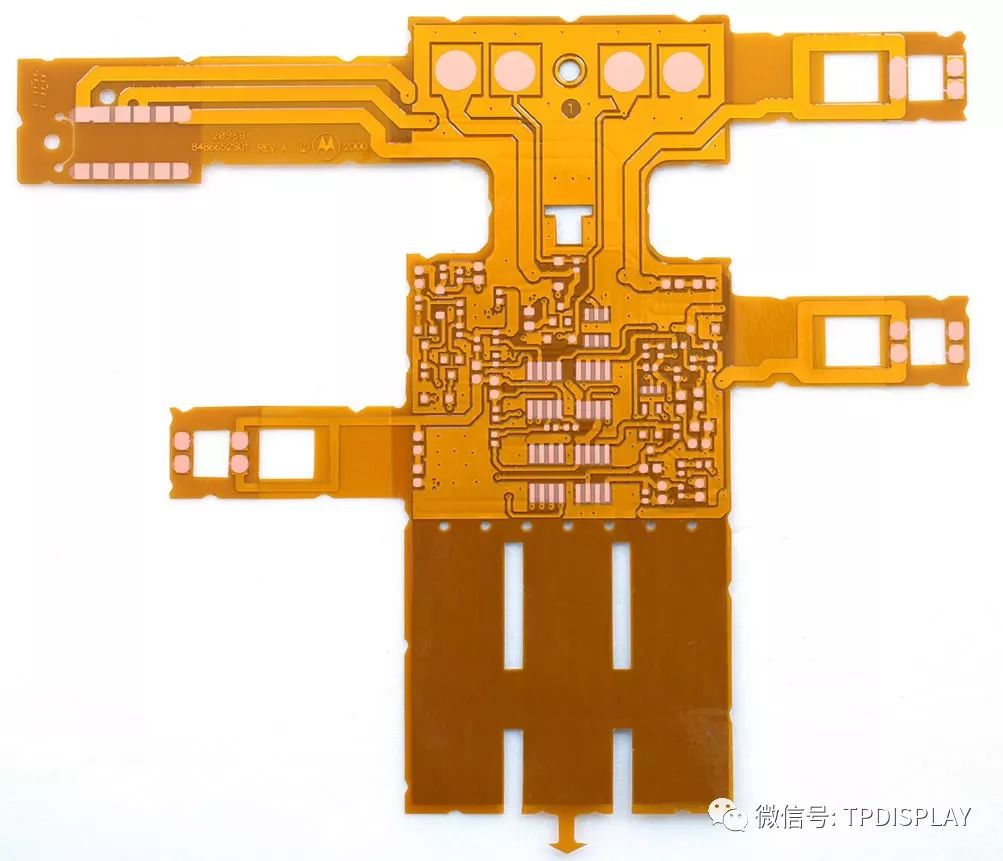

Based on the CAD files of the circuit board, the hole positioning data of the FPC is read to manufacture high-precision FPC positioning templates and dedicated carriers. The diameter of the positioning pins on the positioning template must match the hole diameters of the positioning holes on the carrier and FPC. Many FPCs are not of uniform thickness due to the need to protect certain circuits or design reasons; some areas are thicker while others are thinner, and some even have reinforced metal plates. Therefore, the junction between the carrier and FPC needs to be processed and ground according to the actual situation to ensure that the FPC is flat during printing and placement. The carrier material must be lightweight, high-strength, low heat absorption, and quick to dissipate heat, with minimal warping and deformation after multiple thermal shocks. Common carrier materials include synthetic stone, aluminum plates, silicone plates, and special high-temperature magnetized steel plates.

3. Production Process

Here, we will detail the key points of FPC SMT using a standard carrier as an example. When using silicone plates or magnetic fixtures, fixing the FPC is much easier, eliminating the need for tape, while the key points of the processes such as printing, placement, and soldering remain the same.

1. Fixing the FPC:

Before SMT, the FPC must be accurately fixed to the carrier. It is particularly important to minimize the storage time between fixing the FPC to the carrier and proceeding with printing, placement, and soldering. There are two types of carriers: those with positioning pins and those without. For carriers without positioning pins, they must be used in conjunction with positioning templates that have pins. First, the carrier is placed over the positioning pins of the template, allowing the pins to protrude through the positioning holes on the carrier. The FPC is then placed over the exposed pins one by one and secured with tape, after which the carrier is separated from the FPC positioning template for printing, placement, and soldering. For carriers with positioning pins, several spring positioning pins, approximately 1.5mm long, are already fixed on the carrier, allowing the FPC to be placed directly onto the spring pins and secured with tape. During the printing process, the spring positioning pins can be completely pressed into the carrier by the stencil, without affecting the printing quality.

Method 1 (Single-sided tape fixing): Use thin, high-temperature resistant single-sided tape to secure the four edges of the FPC to the carrier, preventing any shifting or warping. The tape’s adhesion should be moderate, allowing for easy removal after reflow soldering without leaving residue on the FPC. If using an automatic tape dispenser, it can quickly cut consistent lengths of tape, significantly improving efficiency, reducing costs, and avoiding waste.

Method 2 (Double-sided tape fixing): First, apply high-temperature double-sided tape to the carrier, achieving results similar to silicone plates, and then attach the FPC to the carrier. Care must be taken to ensure that the tape’s adhesion is not too high; otherwise, it may easily tear the FPC during removal after reflow soldering. After repeated passes through the oven, the adhesion of the double-sided tape will gradually decrease, and when it becomes insufficient to reliably secure the FPC, it must be replaced immediately. This workstation is critical for preventing FPC contamination, and operators should wear finger cots. Before reusing the carrier, it should be properly cleaned, either by wiping with a non-woven cloth soaked in cleaning solution or using an anti-static dust roller to remove surface dust, solder balls, and other foreign materials. Care should be taken not to apply too much force when handling the FPC, as it is fragile and can easily crease or break.

2. Solder Paste Printing for FPC:

FPC does not have specific requirements for the composition of solder paste; the size of solder balls and metal content should be based on whether there are fine-pitch ICs on the FPC. However, FPC has high requirements for the printing performance of solder paste. The solder paste should have excellent thixotropic properties, allowing for easy printing and release, and should adhere firmly to the FPC surface without causing issues such as poor release, blocked stencil apertures, or collapse after printing.

Since the FPC is mounted on the carrier, and there is high-temperature tape for positioning on the FPC, the surface cannot be as flat and uniform in thickness and hardness as a PCB. Therefore, a metal squeegee should not be used; instead, a polyurethane squeegee with a hardness of 80-90 degrees should be employed. It is best for the solder paste printer to have an optical positioning system; otherwise, the printing quality may be significantly affected. Although the FPC is fixed to the carrier, there will always be some tiny gaps between the FPC and the carrier, which is the biggest difference from rigid PCBs. Therefore, the setting of equipment parameters will also have a significant impact on the printing effect.

The printing workstation is also critical for preventing FPC contamination, and operators should wear finger cots while keeping the workstation clean, frequently wiping the stencil to prevent solder paste from contaminating the FPC’s gold fingers and gold-plated buttons.

3. SMD Placement for FPC:

Depending on the product characteristics, component quantity, and placement efficiency, either medium or high-speed placement machines can be used. Since each FPC has optical MARK markings for positioning, the SMD placement on FPC is not much different from that on PCB. It is important to note that although the FPC is fixed to the carrier, its surface cannot be as flat as a rigid PCB, and there will definitely be local gaps between the FPC and the carrier. Therefore, the height of the nozzle drop, blowing pressure, etc., need to be precisely set, and the nozzle movement speed should be reduced. Additionally, since FPCs are often in panels, and the yield of FPCs is relatively low, it is normal for the entire panel to contain some defective pieces. Thus, the placement machine must have BAD MARK recognition functionality; otherwise, production efficiency will be significantly reduced when producing panels that are not entirely good.

4. Reflow Soldering for FPC:

Forced hot air convection infrared reflow soldering ovens should be used to ensure that the temperature on the FPC changes uniformly, reducing the occurrence of soldering defects. If single-sided tape is used, since it can only fix the four edges of the FPC, the middle part may deform under hot air, causing the pads to tilt, and molten solder (liquid solder at high temperatures) may flow, resulting in cold solder joints, bridging, and solder balls, leading to a higher defect rate.

1) Temperature Curve Testing Method:

Due to the different heat absorption characteristics of the carrier and the different types of components on the FPC, they will experience different rates of temperature rise and heat absorption during the reflow soldering process. Therefore, carefully setting the temperature curve of the reflow soldering oven has a significant impact on soldering quality. A reliable method is to place two boards with FPCs on either side of the test board, while components are mounted on the FPC of the test board. High-temperature solder wire is used to solder the temperature probe to the test points, and high-temperature tape is used to secure the probe wires to the carrier. Care must be taken not to cover the test points with the high-temperature tape. The test points should be selected near the edges of the carrier and at solder joints and QFP pins, as such test results will better reflect the actual situation.

2) Setting the Temperature Curve:

During oven temperature debugging, due to the poor uniformity of FPC, it is best to use a temperature curve method of heating/holding/reflow, as this makes it easier to control the parameters of each temperature zone. Additionally, the impact of thermal shock on the FPC and components will be smaller. Based on experience, it is best to set the oven temperature to the lower limit of the solder paste technical requirements, and the wind speed of the reflow oven is generally set to the lowest speed that the oven can achieve, ensuring good stability of the reflow oven chain without shaking.

5. Inspection, Testing, and Depaneling of FPC:

Since the carrier absorbs heat in the oven, especially aluminum carriers, the temperature is relatively high when they exit the oven. Therefore, it is best to add forced cooling fans at the oven exit to help cool down quickly. At the same time, operators should wear heat-resistant gloves to avoid burns from the high-temperature carrier. When removing the completed FPC from the carrier, force should be applied evenly, and brute force should not be used to avoid tearing or creasing the FPC.

The removed FPC should be visually inspected under a magnifying glass of 5x or more, focusing on checking for residual glue, discoloration, solder on gold fingers, solder balls, cold solder joints, bridging, and other issues. Due to the uneven surface of the FPC, the false positive rate of AOI is very high, so FPCs are generally not suitable for AOI inspection. However, with the help of dedicated testing fixtures, FPCs can complete ICT and FCT testing.

Since FPCs are often in panels, it may be necessary to perform depaneling before conducting ICT and FCT testing. Although tools such as blades and scissors can also complete the depaneling process, the efficiency and quality of the work are low, and the scrap rate is high. For mass production of irregular FPCs, it is recommended to create dedicated FPC stamping depaneling molds for stamping separation, which can significantly improve work efficiency. Additionally, the edges of the stamped FPC will be neat and beautiful, and the internal stress generated during stamping will be low, effectively avoiding solder joint cracking.

In the assembly and soldering process of flexible electronics in PCBA, the precise positioning and fixing of FPC is crucial. The key to proper fixing is the production of suitable carriers. Next are the pre-baking, printing, placement, and reflow soldering of the FPC. Clearly, the SMT process for FPC is much more challenging than that for rigid PCBs, so it is necessary to accurately set process parameters. Additionally, strict production process management is equally important; it is essential to ensure that operators strictly follow every regulation in the SOP, and line engineers and IPQC should strengthen inspections to promptly identify abnormalities on the production line, analyze the causes, and take necessary measures to control the defect rate of the FPC SMT production line to within dozens of PPM.

In the PCBA production process, many machines and equipment are required to complete the assembly of a board, and often the quality level of a factory’s machinery directly determines its manufacturing capability.

The basic equipment required for PCBA production includes solder paste printers, placement machines, reflow soldering ovens, AOI inspection machines, component lead cutting machines, wave soldering machines, soldering furnaces, cleaning machines, ICT testing fixtures, FCT testing fixtures, and aging test racks. The equipment configuration will vary among PCBA processing factories of different scales.

4. PCBA Production Equipment

1. Solder Paste Printer

Modern solder paste printers generally consist of components for board loading, solder paste application, printing, and circuit board transport. Its working principle is to first fix the circuit board to the printing positioning table, and then the left and right squeegees of the printer apply solder paste or red glue through a stencil onto the corresponding pads. For uniformly printed PCBs, they are then fed to the placement machine for automatic placement.

2. Placement Machine

The placement machine, also known as the “pick-and-place machine” or “Surface Mount System,” is configured after the solder paste printer on the production line. It accurately places surface mount components onto the PCB pads using a moving placement head. There are both manual and fully automatic types.

3. Reflow Soldering

The reflow soldering machine has a heating circuit that blows heated air or nitrogen onto the circuit board with mounted components, melting the solder on both sides of the components to bond them to the main board. The advantages of this process include easy temperature control, prevention of oxidation during soldering, and easier control of manufacturing costs.

4. AOI Inspection Machine

AOI (Automatic Optical Inspection) is a device that detects common defects encountered during soldering production based on optical principles. AOI is a rapidly emerging new testing technology, and many manufacturers have introduced AOI testing equipment. During automatic detection, the machine scans the PCB with a camera, collects images, and compares the tested solder joints with qualified parameters in the database. Through image processing, defects on the PCB are identified and displayed/marked on a monitor for repair personnel to address.

5. Component Lead Cutting Machine

This machine is used to cut and deform the leads of through-hole components.

6. Wave Soldering

Wave soldering involves direct contact of the soldering surface of the plug-in board with high-temperature liquid solder to achieve soldering. The high-temperature liquid solder maintains a sloped surface and is made to form waves by special devices, hence the name