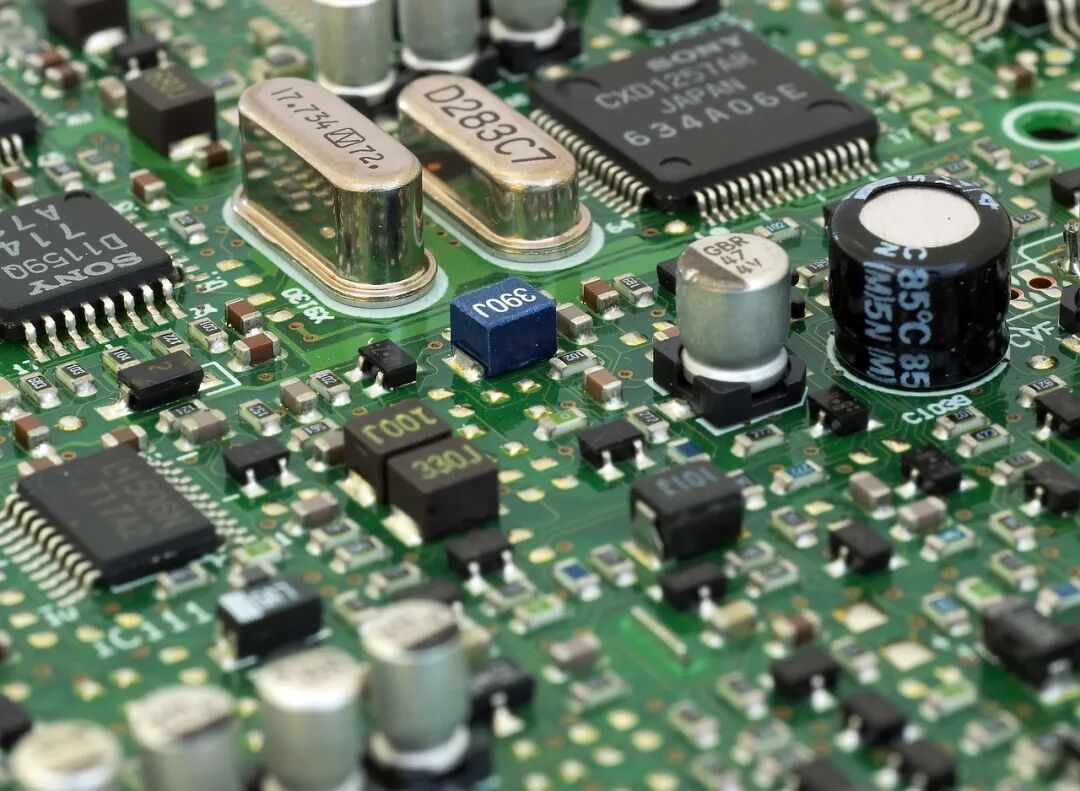

Solder joint processing in printed circuit board assembly (PCBA) is crucial, as the quality of solder joints directly affects the overall performance and reliability of the product. However, during actual production, issues with solder joint failure may arise. How can we reasonably address this problem?

1. Why Do Solder Joints Fail?

① Improper soldering process: Unreasonable settings of parameters such as soldering temperature, time, and pressure, or issues like vibration and misalignment during the soldering process can lead to poor solder joint quality, resulting in failure;

② Material mismatch: Mismatched soldering materials and the materials of the components being soldered, or quality issues with the soldering materials themselves, such as oxidation or contamination, can affect the performance of solder joints;

③ Design defects: Unreasonable PCB design, such as excessively small pad sizes or narrow spacing, or improper component layout can make it difficult for solder joints to form or lead to unstable quality;

④ Environmental factors: Environmental factors during the soldering process, such as humidity, temperature, and air cleanliness, can also impact solder joint quality.

2. How to Address the Causes of Solder Joint Failure?

① Optimize the soldering process: By adjusting soldering parameters, using stable soldering equipment, and enhancing monitoring during the soldering process, ensure the stability and reliability of the soldering process;

② Choose appropriate soldering materials: Select suitable soldering materials based on the materials and performance requirements of the components being soldered, and ensure the quality of the soldering materials meets the requirements;

③ Improve PCB design: Optimize PCB design to ensure pad sizes are appropriate and spacing is reasonable, while also arranging component layout properly to reduce soldering difficulty and the risk of solder joint failure;

④ Improve the soldering environment: Control factors such as humidity, temperature, and air cleanliness in the soldering environment to reduce the impact of environmental factors on solder joint quality;

⑤ Strengthen quality inspection and monitoring: During PCBA processing, enhance quality inspection and monitoring to promptly identify and address solder joint failure issues, ensuring the stability and reliability of product quality.

This article is an original piece by Fanyi Enterprise Training. Please indicate the source when reprinting!

For submissions/recruitment/advertising/course cooperation/resource exchange, please add WeChat: 13237418207