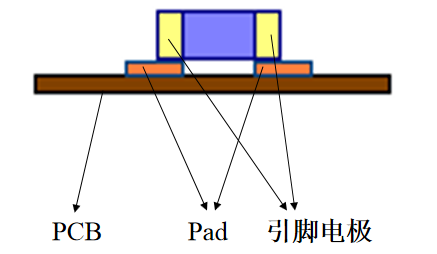

SMT, short for Surface Mount Technology, originated in the 1960s, involves directly mounting SMD components onto PCBs. Its greatest advantage is the high wiring density per unit area of each component, which shortens connection lines and improves electrical performance.

Below, I will quickly guide you through the SMT process flow.

(This is SMT)

01

01

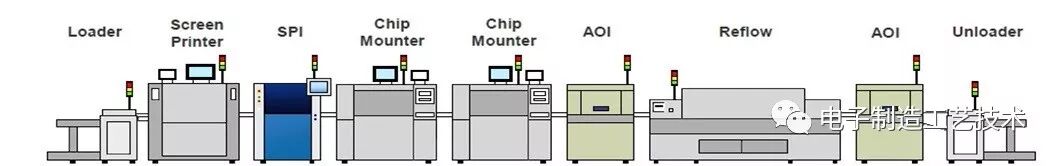

SMT Production Process

1Program the Pick-and-Place Machine

Based on the BOM placement diagram provided by the customer, program the coordinates for the placement of SMD components. Then, verify the first piece against the SMT processing data provided by the customer.

2Print Solder Paste

Use a stencil to apply solder paste to the pads on the PCB where electronic components will be soldered, preparing for component soldering. The equipment used is a screen printer, located at the front end of the SMT processing line.

3SPI

Solder paste inspection equipment checks the printed solder paste for defects such as insufficient solder, missing solder, or excess solder.

4Placement

Accurately install SMD electronic components onto fixed positions on the PCB. The equipment used is a pick-and-place machine, located behind the screen printer on the SMT production line.

Pick-and-place machines are divided into high-speed machines and general-purpose machines.

High-speed machines: Used for components with large pin pitches and small components.

General-purpose machines: Used for components with small pin pitches (dense pins) and larger components.

5High-Temperature Solder Paste Melting

This process involves melting the solder paste at high temperatures, which, upon cooling, securely solder the SMD components to the PCB. The equipment used is a reflow oven, located behind the pick-and-place machine on the SMT production line.

6AOI

Automated Optical Inspection equipment checks for soldering defects such as tombstoning, misalignment, and cold solder joints.

7Visual Inspection

Manual inspection focuses on the following items: whether the PCBA version is the updated version; whether the customer requires the use of substitute materials or specified brands; the orientation of directional components such as ICs, diodes, transistors, tantalum capacitors, aluminum capacitors, and switches; defects after soldering: short circuits, open circuits, counterfeit parts, and cold solder joints.

8Packaging

Qualified products are packaged separately. Common packaging materials include anti-static bubble bags, anti-static foam, and blister trays. There are two main packaging methods: one is to use anti-static bubble bags or anti-static foam rolled up for separate packaging, which is currently the most common method; the other is to customize blister trays according to the size of the PCBA, placing them in the trays for packaging, mainly for PCBA boards with sensitive pins or fragile SMD components.

02

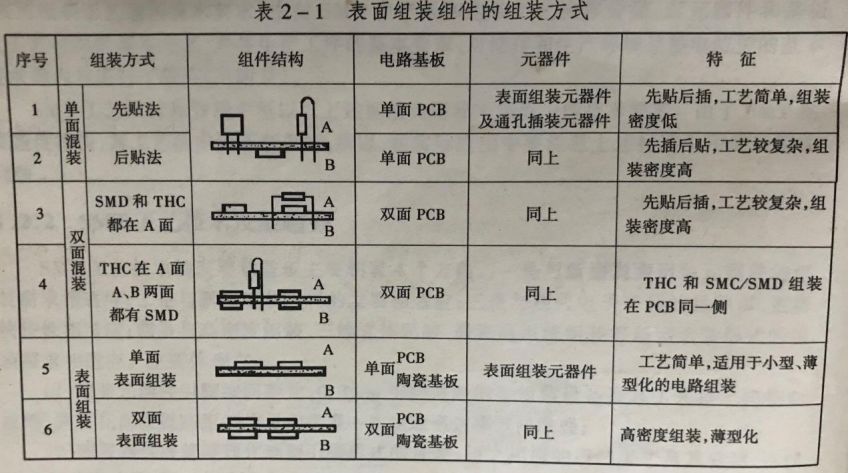

Assembly Methods for SMT Surface-Mounted Components

The main equipment required for PCBA production includes solder paste printers, SPI solder paste inspection machines, pick-and-place machines, reflow ovens, temperature testing instruments, AOI inspection machines, component lead cutting machines, wave soldering machines, solder pots, board washing machines, ICT testing fixtures, FCT testing fixtures, aging test racks, stencil cleaning machines, and X-ray inspection machines. Different scales of PCBA processing factories will have different equipment configurations.

As 5G becomes more widespread, smart living is gradually coming to us. Drones, unmanned vending machines, unmanned supermarkets, autonomous driving, new energy vehicles, and robotic arms for manufacturing are stimulating the electronics industry, which will also change with market demand. Friends interested in investing in PCBA/FPCBA are also eager to try.

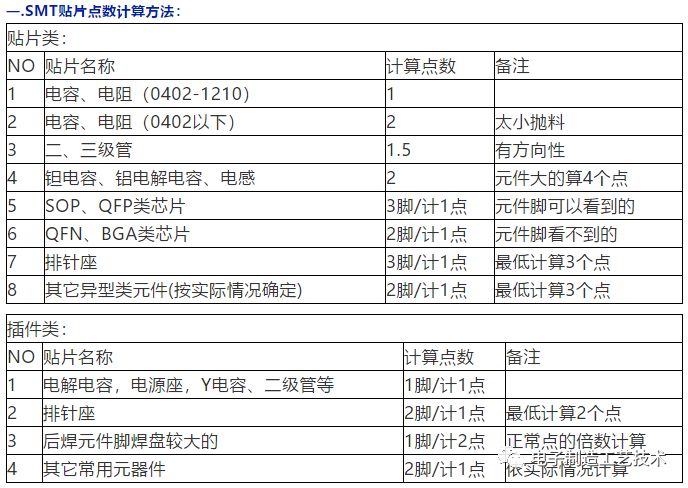

Now, let’s discuss the methods for calculating points and costs in SMT processing.

The current SMT processing methods mainly include: lead-free soldering, leaded soldering, and red glue soldering. The methods for calculating points are similar, but many users are not very clear about how to calculate the points and costs for SMT processing. Today, I will share the methods for calculating points and costs in SMT processing:

Some companies calculate one pad as one point, while others may count two pads as one point. This article takes the pad calculation as one point as an example. You only need to count the total number of pads on the PCB. However, for some special components, such as inductors, large capacitors, and ICs, specific calculations are required. For example, an inductor can be counted as 10 points, and an IC can be counted as half the number of pins (for example, a 40-pin IC counts as 20 points). Using this method, you can easily calculate the total number of solder points on the entire PCB.

2. Unit Price of Solder Points:

Currently, the market price for solder points varies, ranging from 0.008 to 0.03 yuan per solder point, depending on the following conditions:

1. Unit price by process:

A Solder paste with lead for SMT processing is relatively inexpensive.

B Lead-free solder paste for SMT processing has a relatively higher cost.

C Eco-friendly red glue SMT processing has a relatively low cost.

D Dual-process SMT processing with solder paste and red glue has a high cost and is relatively complicated.

2. By order quantity:

A Common SMT prototype processing for 3-20 pieces will incur an engineering fee and will not be calculated by multiplying points by unit price.

B Small batch SMT processing for less than 1000 pieces will incur a setup fee plus points multiplied by unit price.

C Bulk SMT processing will be calculated by multiplying points by unit price.

3. By board complexity:

A Single-sided SMT processing is relatively faster, while double-sided SMT processing requires two passes, resulting in higher costs.

B Precision level: More precise SMT processing, such as BGA or high-density ICs, will use more expensive solder paste.

C Density of SMD components: More points in the same size PCB will increase efficiency, as the pick-and-place machine will have shorter travel distances, speeding up SMT processing.

4. Setup fee: For small batch orders with a processing fee of less than 1000 yuan, the setup fee will vary from 400 to 2000 yuan depending on the type of components on the board, the time required to debug the pick-and-place machine, and the difficulty of making the first piece.

5. Prototyping fee: For SMT processing orders of less than 100 pieces, the prototyping fee will vary from 800 to 3000 yuan depending on the complexity of the board, programming time, and setup time.

6. Stencil fee: Different stencil models are required based on the size of the PCB. Depending on the precision of the chips on the PCBA, either electric polished stencils or standard stencils will be chosen. The cost of different stencil models ranges from 120 to 350 yuan. Of course, customers can also provide their own stencils.

3. Calculation of SMT processing costs:

1. Calculation of processing costs = points * unit price per point (processing costs include: red glue, solder paste, AOI inspection, X-ray inspection, etc.)

Extract the essence, discard the dross, focus on the basics, and promote innovation

Note: Many fans have not yet developed the habit of liking and sharing after reading. I hope everyone will take a moment to like and share after reading to show encouragement! It is not easy for a team to persist for a long time, and we have thought about giving up many times. Persistence is a belief, and focus is an attitude!

More and more people are paying attention to us, come join this big team!

Disclaimer: This article is an original compilation of information collected from the internet, and the copyright belongs to the original author. Please indicate the source when reprinting. If there are any issues with the work, please contact us.

If you need soft articles or image advertising business cooperation, please contact us.