Follow 👆 Modern Electronic Assembly Process Technology Exchange Platform👆 Select “Pin/Star” to learn together and improve together!

Previous Reviews

Collection of Assembly Process Documents:

↓ ↓ ↓

Essentials | Selected Assembly Process Document Collection (I): Save it for later!

Essentials | Selected Assembly Process Document Collection (II): Save it for later!

Essentials | Selected Assembly Process Document Collection (III): Save it for later!

Essentials | Selected Assembly Process Document Collection (IV): Save it for later!

Essentials | Selected Assembly Process Document Collection (V): Save it for later!

Training Schedule for Master and Doctor Students in June-July<br/>Teacher Cong Phone: 13810257238 (same as WeChat)<br/>Click the title link below ↓ ↓ ↓ to enter course details<br/><br/>Chengdu | QC Tools and Techniques to Effectively Solve On-Site Problems (June 15-16)<br/>Hangzhou | Weapon Equipment Development Technology Status Management and GJB3206B Application Technology (June 15-16)<br/>Shanghai | DFX Analysis and Application Technology Advanced Training Course (June 27-28)<br/>Yangzhou | Equipment Development Price Review and Practical Case Analysis Advanced Training Course (June 28-29)<br/>Beijing | Electronic Assembly Process Technology - Inspection and Control Process (June 29-30)<br/>Hangzhou | Advanced Training Course on Thermal Design, Thermal Analysis, and Thermal Testing of Electronic Products (June 29-30)<br/>Wuxi | New Version 81 - Military Product Equipment Certification and Review (July 06-07)<br/>Xi'an | Multi-Variety, Small Batch, Short Lead Time Production Management Technology Advanced Training Course (July 12-13)<br/>Chengdu | Aerospace Process Management Technology (July 13-14)<br/>Shanghai | Reliability Testing and Accelerated Testing Technology (July 13-14)<br/>Chengdu | Quality Management Statistical Techniques and Quality Data Analysis Practical Course (July 18-19)<br/>Beijing | SMT Soldering Process Misconceptions and Blind Spots (July 19-20)<br/>The protective function of conformal coating has led to its increasing application in electronic products. However, due to factors such as process or inherent properties, some issues may arise during the use of conformal coating. Here, I will share some common problems and solutions encountered during the use of conformal coating for your reference.

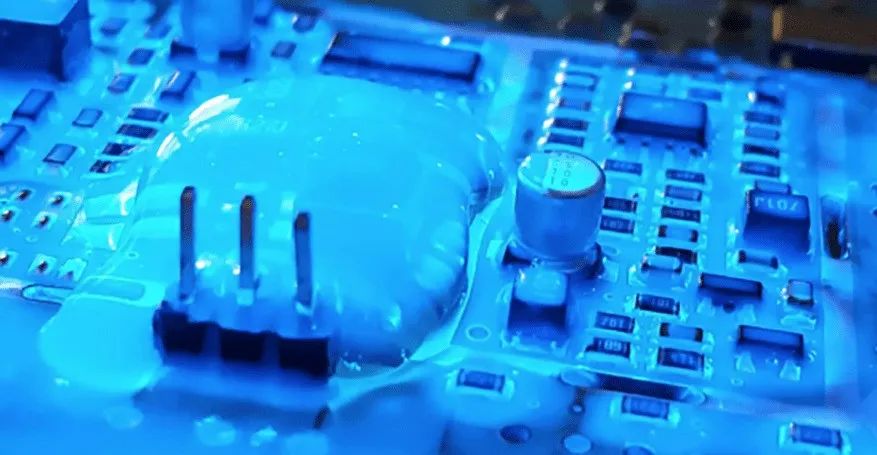

Bubbles

Bubbles refer to the formation of raised circular blisters of varying sizes on the dried coating film, also known as blistering, occurring between the coated surface and the coating film, or between two layers of coating film. Bubbles with a diameter greater than 300 microns are called large bubbles, while those smaller than 300 microns are called small bubbles. The main causes of bubble formation are: excessive solvent remaining in the coating film; high oven temperature causing rapid skinning of the surface; high viscosity of the conformal coating preventing bubbles from escaping quickly; excessive thickness of the conformal coating preventing bubbles from escaping quickly; and excessive or insufficient exhaust in the leveling and evaporation area. Solutions ① Degas the adhesive before use or use vacuum degassing. ② Clean the PCB board before coating to prevent impurities from affecting the adhesive’s adhesion. ③ Control the viscosity and flow of the adhesive during coating. ④ Control the spraying pressure and baking temperature of the equipment.

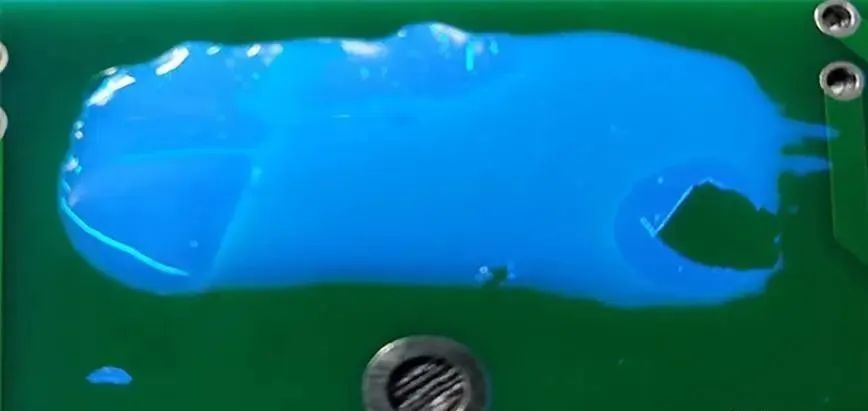

Whitening

Whitening refers to the presence of moisture or other liquids in the conformal coating film, resulting in a lighter white color compared to the original, presenting a white mist appearance. The main causes of whitening are: high environmental humidity; excessive moisture content in the substrate, causing moisture to evaporate and accumulate in the coating film leading to whitening; moisture in the PCBA surface, container, or conformal coating; and rapid evaporation of the thinner. Solutions ① Dry the substrate before application to control its moisture content. ② Avoid applying thick layers of conformal coating at once. ③ Apply in a low humidity environment (<75%); if necessary, add an appropriate slow-drying solvent. ④ Ensure the PCBA surface is clean and dry, free from moisture. ⑤ Prevent moisture from mixing into the conformal coating and container.

Delamination

In the PCBA production process, the use of conformal coating on the PCB board is the final step. To enhance the surface’s wear resistance, wettability, and aesthetic appearance, flux is often used before applying the conformal coating. If not cleaned thoroughly, chemical residues may remain on the board, affecting the compatibility of the conformal coating layer. Over time, the coating film may slowly detach from the PCB board, resulting in delamination. Solutions ① Clean and dry the circuit board before applying the conformal coating to reduce film thickness. ② When removing protection, if delamination occurs and the coating adhesion is poor, the coating should be removed when it reaches touch-dry (still soft).

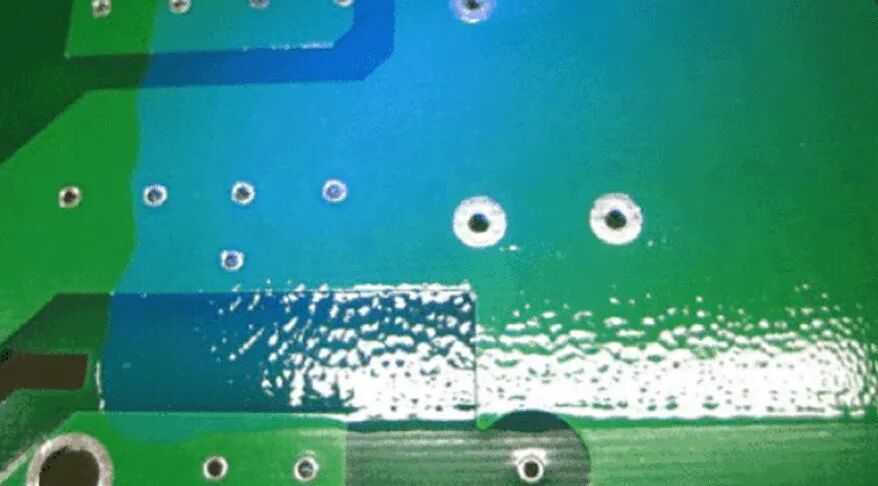

Orange Peel

After spraying the conformal coating, it generally self-levels on the PCB board. In some automated spraying processes, leveling is controlled by the conveyor speed, and rapid evaporation of the thinner and high viscosity can lead to uneven areas that result in an orange peel effect. High production environment temperatures can accelerate solvent evaporation, preventing the adhesive from leveling completely, which can also lead to slight orange peel. In short, the orange peel phenomenon occurs due to forced curing. Solutions ① Check the production environment, such as temperature and humidity. ② Compare boards cured at room temperature with those cured under normal processes. ③ Reduce the exhaust in the leveling and evaporation area before curing. ④ Lower the viscosity of the conformal coating. ⑤ Reduce the ramp rate of the oven temperature curve. ⑥ Use a slower evaporating thinner.

Capillary Action

The capillary flow of conformal coating refers to the movement of material from certain areas to others due to capillary action, resulting in inconsistent results. In the best case, the resulting conformal coating is uneven and sporadic; in the worst case, it can lead to coating detachment, leaving the substrate completely exposed. The main causes of capillary action are: small spacing between connector legs in the board design; overly stringent coating requirements; low viscosity of the conformal coating; excessive flow of conformal coating; and inappropriate surface tension between the substrate and conformal coating. Solutions ① Increase the distance between the coating area and the connectors. ② Use masking tape around the connectors to form a barrier. ③ Use a higher viscosity conformal coating. ④ Reduce film thickness. ⑤ Clean the circuit board.

Cracks and Scratches

Cracks occur due to excessive film thickness, primarily appearing at the pins and edges of components where surface tension is high. Scratches come from mechanical damage during the coating process. Solutions ① Reduce film thickness. ② Optimize the oven temperature curve; the oven temperature should not be too high, allowing the coating film to dry and cure slowly for optimal performance. ③ Pay attention to reducing scratches during the coating drying and packaging process.

Long press to recognize the QR code to follow the [Modern Electronic Assembly Process Technology] subscription account and start our learning journey together.

Editor’s Note

Copyright Statement: The Modern Electronic Assembly Process Technology Exchange Platform respects copyright and appreciates the hard work and creativity of every author. If any article or image content involves copyright, please contact us immediately, and we will delete it promptly. Administrator WeChat: c-f790582797

Excellent articles will enrich and increase your knowledge, charging a little every day, improving a little every day.

Every click on "Read" is taken seriously as a like.

end

Share

Collect

Like

View