Market Research and Development Forecast Report on Solder Paste Inspection (SPI) Systems in China (2025-2031)

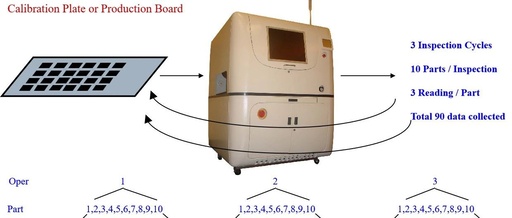

Report Title:Market Research and Development Forecast Report on Solder Paste Inspection (SPI) Systems in China (2025-2031)Table of Contents According to the latest research by QYR, the sales revenue of the solder paste inspection (SPI) system market in China reached ¥ million in 2024, and it is expected to reach ¥ million by 2031, with a … Read more