Tungsten in the field of PCB (Printed Circuit Boards) is primarily applied in interconnection materials and advanced packaging technologies. Its high electrical conductivity, high-temperature resistance, and anti-electromigration properties make it a critical material. Below is a detailed analysis of applications and consumption:

1.Core Application Scenarios

(1)Interconnection Materials and Via Filling

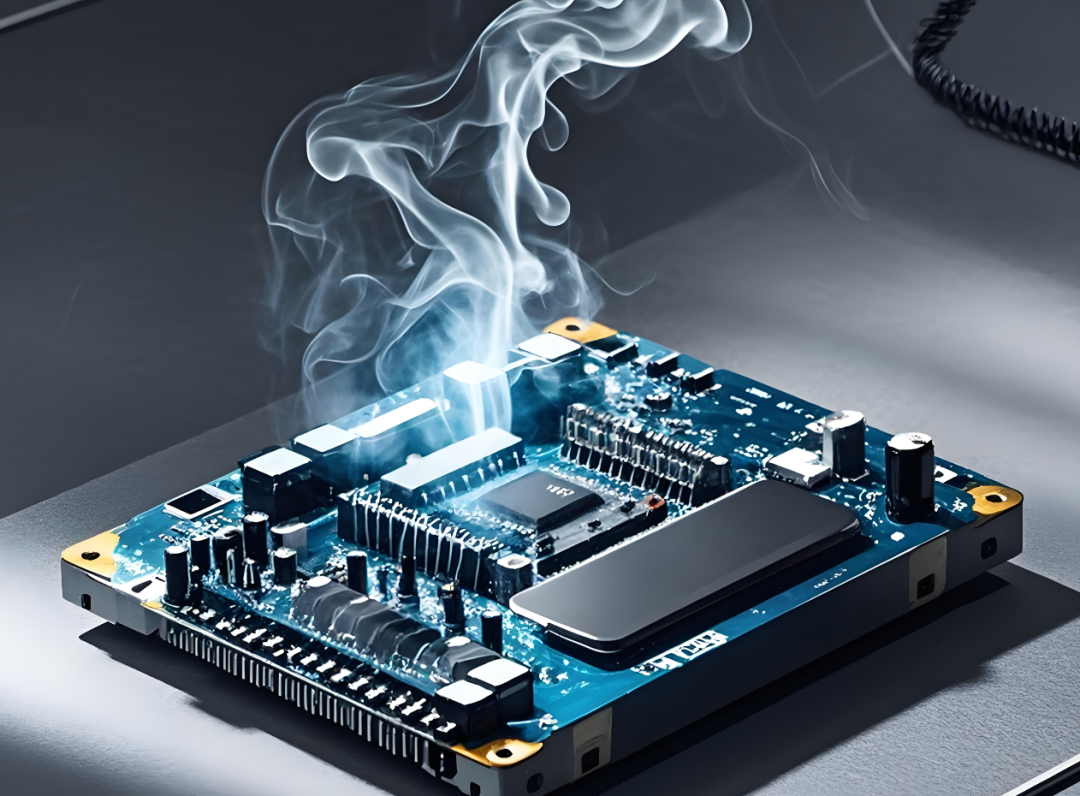

Tungsten forms conductive layers for vias and contact holes through chemical vapor deposition (CVD) processes, connecting metal lines in multilayer PCB structures. Its low resistivity (5.6×10⁻⁸Ω·m) and high melting point (3422℃) can withstand high-temperature reflow soldering processes, ensuring circuit stability.

(2)Application of Tungsten Hexafluoride (WF₆) in CVD Processes

Tungsten hexafluoride is the main precursor for semiconductor-grade tungsten thin film deposition, used in the preparation of high-density interconnect layers for PCBs. By 2025, the demand for WF₆ in China’s semiconductor industry is expected to reach 2800 tons (metal equivalent), with PCB manufacturing accounting for a significant proportion.

(3)Application of Nano Tungsten Oxide in Storage Components

In high-end PCBs equipped with resistive random-access memory (RRAM), nano tungsten oxide serves as the storage medium, achieving data storage through resistance changes, thereby enhancing PCB integration. Although the current industrial scale is small, laboratory data shows significant potential in high-density storage fields.

2.Consumption Analysis

(1)Direct Material Demand

1. Tungsten target materials: Used in physical vapor deposition (PVD) processes, with a projected demand of 4000 tons by 2025.

2. Tungsten polishing slurry: Used in chemical mechanical polishing (CMP) for PCB micro-hole processing, with a global market growth rate exceeding 8%, and China accounting for about 35%.

(2)Indirect Demand Drivers

1. Advanced process promotion: Chips below 3nm require finer line widths, driving the demand for high-purity tungsten interconnect layers and increasing WF₆ consumption in CVD processes.

2. Packaging technology upgrades: 2.5D/3D packaging relies on tungsten via technology, with tungsten usage in a single high-end PCB increasing by 20%-30% compared to traditional products.

3.Technical Trends and Challenges

Domestic substitution acceleration: Chinese PCB companies are gradually adopting domestic tungsten target materials and CMP polishing slurries to reduce dependence on imports.

Environmental requirements enhancement: The greenhouse effect potential value (GWP) of tungsten hexafluoride is high, promoting the research and development of low-emission alternative processes.

4.Conclusion

The demand for tungsten in the PCB field continues to grow with the development of high-density interconnects and advanced packaging technologies. By 2025, tungsten consumption in China’s semiconductor industry is expected to reach 6000-8000 tons, with PCBs accounting for about 15%-20%. In the future, optimizing the performance of tungsten materials and building a domestic supply chain will be key breakthrough directions for the industry.