PCB (Printed Circuit Board) is the supporting body for electronic components. Because it is made using electronic printing techniques, it is referred to as a “printed” circuit board.

Before the advent of PCBs, circuits were made by point-to-point wiring. This solution had low reliability because as the circuit aged, line breakage could lead to open or short circuits at the nodes.

As electronic products increasingly appeared in the Internet of Things (IoT) devices, manufacturers sought smaller and more cost-effective solutions, leading to the birth of the PCB.

The manufacturing of PCBs is very complex. Taking a four-layer printed circuit board as an example, the production process mainly includes PCB layout, core board production, inner layer PCB layout transfer, core board drilling and inspection, lamination, drilling, copper plating of hole walls, outer layer PCB layout transfer, and outer layer PCB etching.

The first step in PCB manufacturing is organizing and checking the PCB layout. The PCB manufacturing factory receives CAD files from the PCB design company. Since each CAD software has its unique file format, the PCB factory converts it to a unified format—Extended Gerber RS-274X or Gerber X2. Then, the factory engineers check whether the PCB layout meets the manufacturing process and whether there are any defects.

Clean the copper-clad board, as dust may cause short circuits or open circuits in the final circuit.

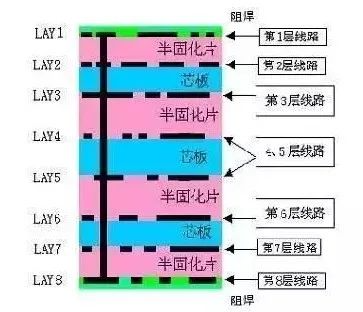

The image below is a diagram of an 8-layer PCB, which is actually made up of 3 copper-clad boards (core boards) plus 2 copper films, and then bonded together with prepreg. The production sequence starts from the innermost core board (layers 4 and 5), continuously stacking together and then fixing. The production of a 4-layer PCB is similar, but it only uses 1 core board plus 2 copper films.

3. Inner Layer PCB Layout Transfer

First, the two layers of circuits for the innermost core board (Core) must be produced. After cleaning the copper-clad board, a photosensitive film is applied to the surface. This film solidifies when exposed to light, forming a protective layer on the copper foil of the copper-clad board.

The two-layer PCB layout film and the double-layer copper-clad board are then inserted with the upper layer PCB layout film to ensure the precise alignment of the upper and lower PCB layout films.

The UV lamp of the photo-etching machine irradiates the photosensitive film on the copper foil. Under the transparent film, the photosensitive film solidifies, while the film that is not exposed to light remains uncured. The copper foil under the solidified photosensitive film is the desired PCB layout circuit, akin to the role of ink in a laser printer for manual PCBs.

Then, alkaline solution is used to wash away the uncured photosensitive film, leaving the required copper foil circuits covered by the solidified photosensitive film.

Then use strong alkali, such as NaOH, to etch away the unnecessary copper foil.

Peel off the solidified photosensitive film to reveal the desired PCB layout circuit copper foil.

4. Core Board Drilling and Inspection

The core board has been successfully produced. Next, alignment holes are drilled into the core board to facilitate alignment with other materials.

Once the core board is pressed together with other layers of PCB, it cannot be modified, so inspection is very important. Machines will automatically compare with the PCB layout drawings to check for errors.

This requires a new material called prepreg, which acts as an adhesive between core boards (for PCBs with more than 4 layers) and between core boards and outer copper foils, while also providing insulation.

The lower copper foil and two layers of prepreg have already been positioned using alignment holes and fixed to the lower iron plate, then the completed core board is placed into the alignment holes, and finally, two layers of prepreg, one layer of copper foil, and one layer of pressure-bearing aluminum plate are sequentially covered onto the core board.

The PCB boards clamped by the iron plates are placed on a rack and sent into a vacuum hot press for lamination. The high temperature in the vacuum hot press melts the epoxy resin in the prepreg, fixing the core boards and copper foils together under pressure.

After lamination is completed, the upper iron plate that pressed the PCB is removed. Then the pressure-bearing aluminum plate is taken away, which also serves to isolate different PCBs and ensure the smoothness of the outer copper foil. At this point, the PCB taken out will be covered on both sides with a layer of smooth copper foil.

To connect the four layers of non-contact copper foils in the PCB, first, through holes must be drilled to penetrate the PCB, and then the walls of the holes must be metallized to conduct electricity.

Using an X-ray drilling machine, the inner core board is positioned. The machine automatically finds and locates the hole positions on the core board, then drills positioning holes into the PCB to ensure that the drilling will pass through the center of the hole positions.

Place a layer of aluminum plate on the drilling machine’s workbench, and then place the PCB on top. To improve efficiency, depending on the number of layers in the PCB, 1 to 3 identical PCBs may be stacked together for drilling. Finally, an aluminum plate is placed on the top PCB; the two layers of aluminum plates prevent tearing of the copper foil on the PCB during the drilling process.

In the previous lamination process, the melted epoxy resin was squeezed out onto the PCB surface, so it needs to be removed. The mold milling machine cuts the perimeter according to the correct XY coordinates of the PCB.

7. Copper Chemical Deposition on Hole Walls

Since almost all PCB designs use through holes to connect different layers of circuits, a good connection requires a 25-micron copper film on the hole walls. This thickness of copper film needs to be achieved through electroplating, but the walls of the holes are made of non-conductive epoxy resin and fiberglass.

Therefore, the first step is to first deposit a layer of conductive material on the hole walls, forming a 1-micron copper film on the entire PCB surface, including the hole walls, through chemical deposition. The entire process, including chemical treatment and cleaning, is controlled by machines.

Fixing the PCB

Cleaning the PCB

Transporting the PCB

8. Outer Layer PCB Layout Transfer

Next, the outer layer PCB layout will be transferred to the copper foil. The process is similar to the previous inner layer core board PCB layout transfer principle, utilizing photocopying films and photosensitive films to transfer the PCB layout onto the copper foil; the only difference is that positive films will be used for the outer layer.

The inner layer PCB layout transfer uses a reduction method, using negative films. The areas on the PCB covered by solidified photosensitive films are the circuits, while the uncured photosensitive films are washed away, and the exposed copper foils are etched, leaving the PCB layout circuits protected by the solidified photosensitive films.

The outer layer PCB layout transfer uses a normal method, using positive films. The areas on the PCB covered by solidified photosensitive films are the non-circuit areas. After washing away the uncured photosensitive films, electroplating is performed. The areas with the film cannot be electroplated, while the areas without the film are first plated with copper and then with tin. After removing the film, alkaline etching is performed, followed by tin removal. The circuit patterns remain on the board due to the protection of the tin.

Clamp the PCB with clips and proceed with the copper electroplating. As previously mentioned, to ensure that the hole positions have sufficient conductivity, the copper film electroplated on the hole walls must have a thickness of 25 microns, so the entire system will be automatically controlled by a computer to ensure accuracy.

9. Outer Layer PCB Etching

Next, a complete automated assembly line will complete the etching process. First, the solidified photosensitive film on the PCB board is washed away. Then strong alkali is used to remove the unnecessary copper foil covered by it. After that, the tin plating on the PCB layout copper foil is removed with a tin stripping solution. After cleaning, the 4-layer PCB layout is complete.

Follow the Metal Processing Video Account for insightful industrial media

☞Source: Mechanical Master ☞Responsible Editor: Shao Yujie ☞Proofreader: Wang Jiahui ☞Reviewer:Wu Xiaolan ☞Media Cooperation: 010-88379790-801

Statement: If there are any copyright issues with the videos, images, or text used in this article, please inform us immediately. We will confirm the copyright based on the proof materials you provide and pay remuneration according to national standards or delete the content immediately!