As one of the top ten motion control brands globally, Trio has a strong competitive advantage in the field of motion control. Today, we will comprehensively introduce the advantages and selection of the Trio series motion controllers!

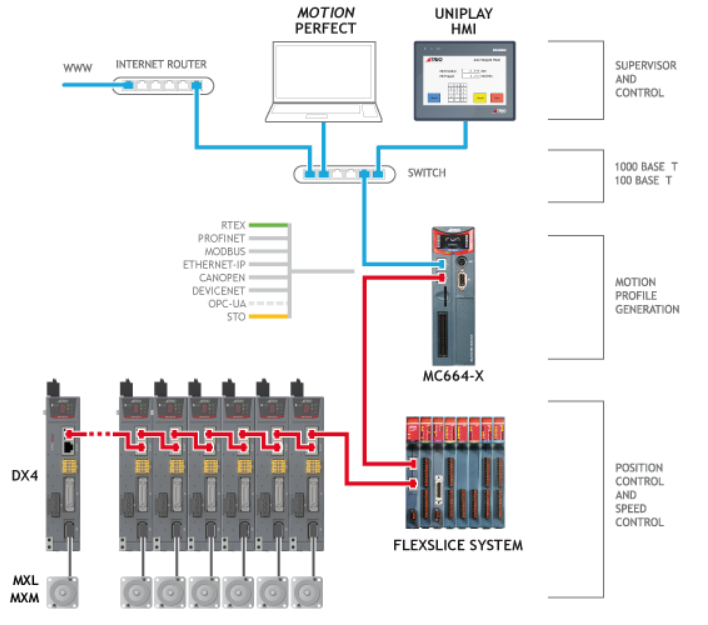

The Trio series products can be divided into four layers: interaction layer, data communication layer, motion control layer, and execution layer.

Among them, Trio’s Motion Perfect V5 software provides users with an ALL IN ONE interactive experience, allowing unified management and debugging of programming environments, touch screens, controllers, various functional modules, servo drives, and motors through a single software.

Topology diagram of the complete solution for Trio products

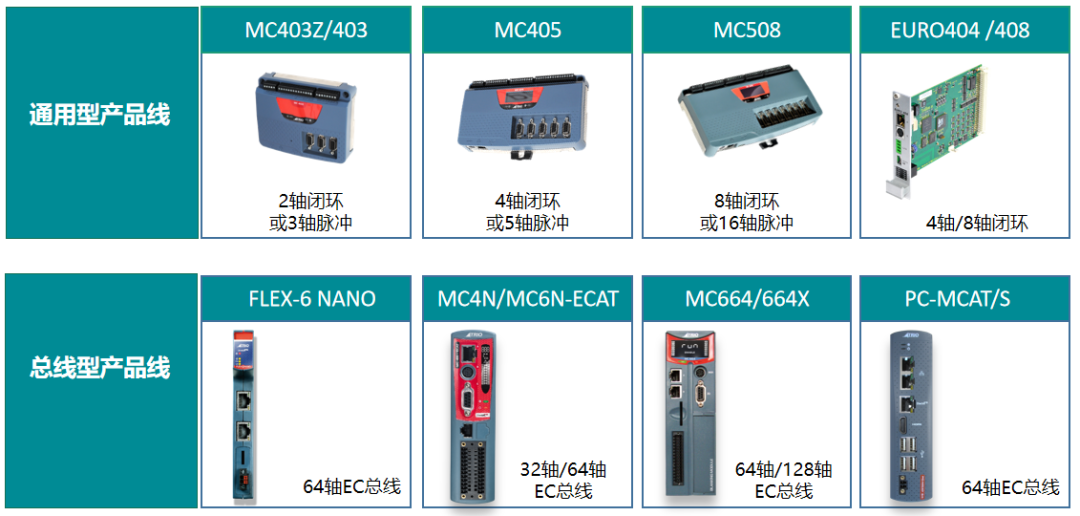

Two main product lines of TRIO controllers: General-purpose and Bus-type

General-purpose controllers

(1) Advantages of general-purpose controllers: Trio’s general-purpose products support analog closed-loop control and pulse control, with different models controlling different numbers of axes, achieving control of 2-8 axes.

General-purpose controller

(2) Interface expansion methods for general-purpose motion controllers:

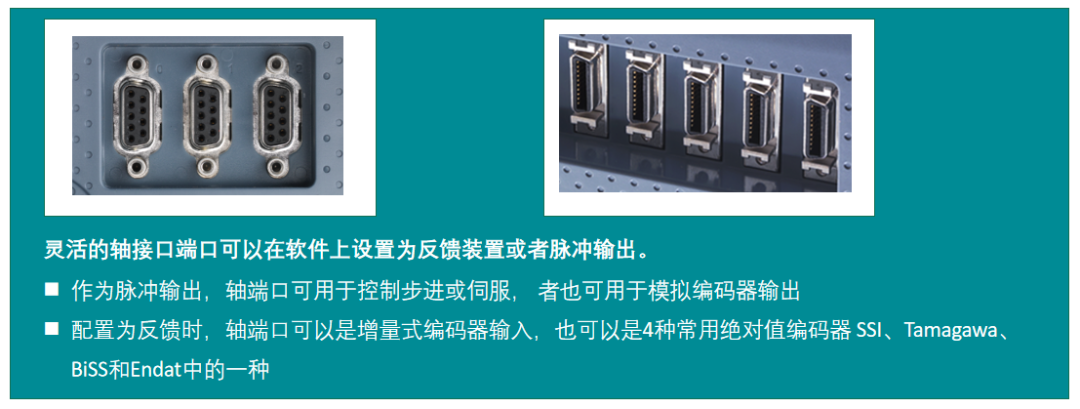

General-purpose controller interface

Standard axis port and high-density axis port

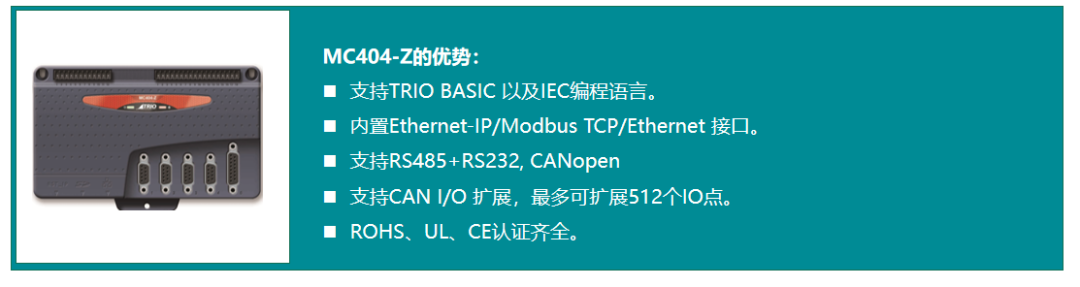

(3) New general-purpose controller: MC404Z – ultra-economical controller

MC404-Z is a newly designed economical controller, featuring a fixed number of axes (4 axes), and does not support any form of axis upgrade package.

Bus-type controllers

(1) Advantages of Trio bus-type controllers:

Trio’s bus-type products support the EtherCAT bus across the entire series, while also supporting mainstream bus protocols such as RTEX, CANopen, Modbus, and Profinet.

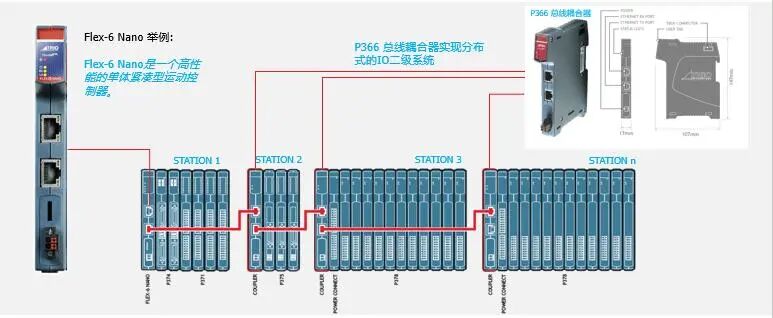

(2) The Trio bus-type controller, with the ultra-economical Flex-6-NANO, can control up to 64 axes.

Flex-6-NANO series controller

(3) MC4N, MC6N bus series controllers

The MC4N series supports the RTEX bus protocol.

MC4N, MC6N series controllers

(4) MC664/664X series controllers

MC664/664X series controllers

The MC664/664X series can achieve synchronous control of up to 128 axes, with the fastest update cycle of 50 µs, providing strong advantages in complex automation equipment applications, particularly in winding machines, lithium battery winding equipment, stacking equipment, textile machinery, and printing machines.

The EtherCAT database of Trio controllers can adapt to most third-party I/O or servos on the market, achieving plug-and-play functionality.

The dedicated EtherCAT master Ethernet port of the motion controller can enable data packets with less than 1μsec vibration, and the servo communication cycle can be adjusted according to customer needs and the actual number of mounted axes. The intelligent drive tool can also display the devices on the user’s network and their connection order and topology in real-time, facilitating user adjustments and positioning. Compared to standalone controllers, bus controllers only add drive settings and process alarms based on the EtherCAT bus. Since all programming is handled in one place, machine control becomes unprecedentedly simple.

Rich I/O expansion methods of TRIO:

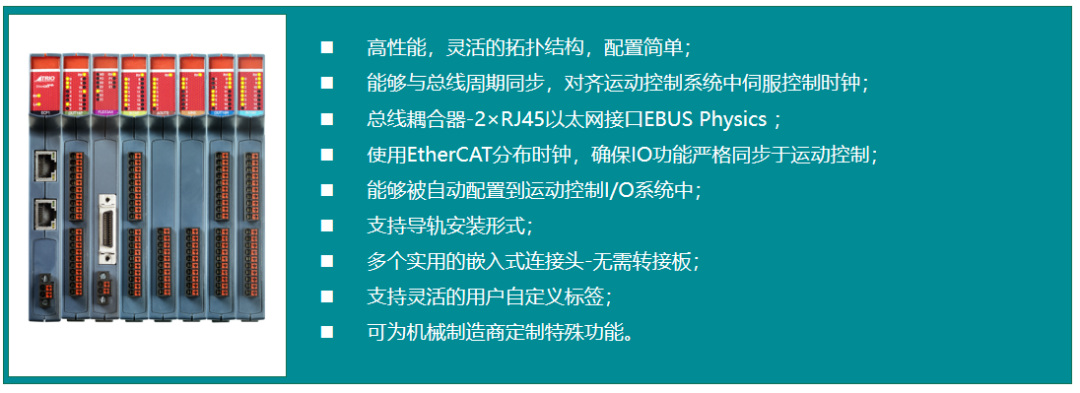

(1) Bus I/O expansion – EtherCAT Flex IO:

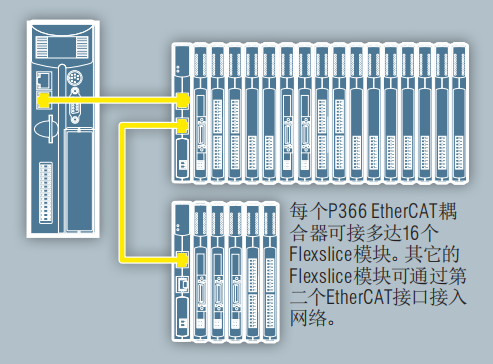

(2) Schematic diagram of bus module connection/expansion

(3) Types of EtherCAT expansion modules

TRIO Input and Output Module Expansion Rules

(1) Digital input and output expansion:

Using the CAN bus protocol, one motion controller can be paired with 16 DI modules and 16 DO modules, totaling 32 digital modules. The CAN I/O module can expand up to 512 I/O points (512 inputs and 512 outputs).

Each P366 Flexslice EtherCAT coupler can support up to 16 Flexslice modules, and other Flexslice modules can be connected to the network via a second EtherCAT interface. The EtherCAT bus system can expand up to 1024 I/O points (1024 inputs and 1024 outputs).

(2) Analog input and output expansion:

Using the CAN bus protocol, one motion controller can be paired with 4 analog modules, allowing for a maximum of 32 channels of 12-bit analog input expansion, or up to 16 channels of 12-bit analog output.

Industry Application Cases and Advantages of TRIO Controllers

Trio controllers have been installed and operated in hundreds of thousands of units globally, demonstrating excellent performance in complex, high-precision, and high-response devices.

Based on the ESTUN + Trio intelligent control unit, the Trio motion controller simultaneously controls robots and multiple external axes, achieving a balance between economy and high performance.

Additionally, the robot control, SCARA, and DELTA robot simulation functions provided by Trio have received high praise from domestic and international enterprises.

Advantages of Trio Controllers:

(1) Mature and Stable:

-

Over 30 years of engineering and application experience;

-

MC403 average time between failures of 322,360 hours;

-

Failure rate of less than or equal to 3 per million hours.

(2) Strong Compatibility:

-

Supports over 100 global servo brands with self-recognition software;

-

Supports various bus modes: Modbus/CANOpen/EtherCAT/RTEX/SERCOS, etc.;

-

Supports various communication methods: “Anybus” module.

(3) Powerful Functions:

-

Color mark capture, with a response speed of up to 20us;

-

Multi-axis interpolation and synchronization for complex movements, with up to 64 axes for interpolation/synchronization;

-

Electronic cam functions, such as flying shear and punching machines;

-

Robot control, supporting robot coordinate system transformation, such as DELTA/SCARA, and integration of peripheral devices, supporting 3D simulation of robot models.

(4) Easy to Learn and Use:

-

Complies with IEC-61131-3 standards, combining algorithms and logic;

-

MotionPerfect software is easy to set up, program, and debug;

-

Supports various auxiliary tools: simulation, OCT controls, 3D digital oscilloscopes.

☞ Source: Estun Automation

☞ Advertising Cooperation: Sun Ha 13811718902

Statement: If there are any copyright issues regarding the videos, images, or text used in this article, please inform us immediately, and we will confirm the copyright based on the proof materials you provide and pay remuneration according to national standards.

Statement: If there are any copyright issues regarding the videos, images, or text used in this article, please inform us immediately, and we will confirm the copyright based on the proof materials you provide and pay remuneration according to national standards.