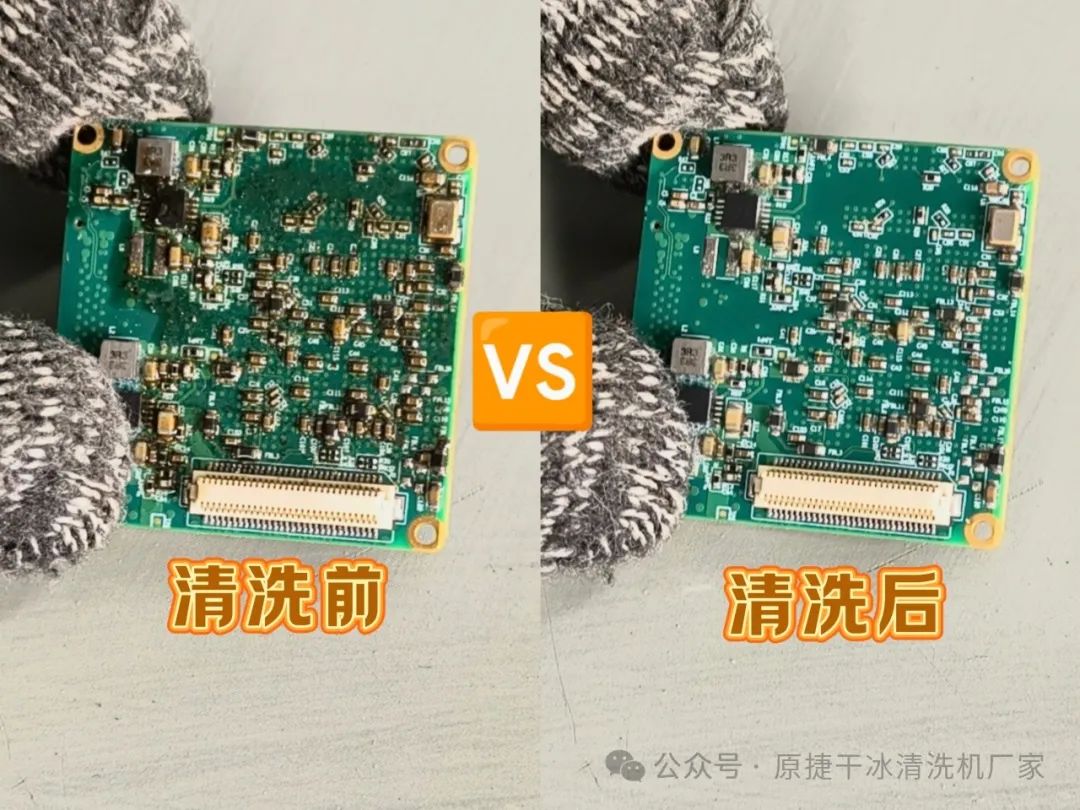

The “Fatal Flaw” of Traditional Cleaning Methods

As the “heart” of electronic devices, the stability of circuit boards directly affects the lifespan of the equipment. Traditional cleaning methods (such as alcohol wiping, water washing, and brush cleaning) are widely used but harbor hidden dangers:

• Water washing: Easily leaves moisture that can cause short circuits and corrosion of the circuit board;

• Solvent cleaning: Chemical agents may corrode components, and volatile gases pose health risks;

• Manual brushing: Low efficiency, difficult to reach dense solder points, and may scratch precision circuits.

These issues can be perfectly resolved with dry ice cleaning!

Dry Ice Cleaning: A “Gentle Strike” for Circuit Boards

Principle: The dry ice cleaning machine accelerates and sprays dry ice particles at -78.5℃ onto the surface of the circuit board, utilizing three main actions to remove dirt:

Low-temperature embrittlement: Dirt contracts and falls off when exposed to cold

Impact stripping: High-speed airflow strips stubborn stains

Sublimation with no residue: Dry ice vaporizes directly, leaving no liquid or chemical residue.

The Five Core Advantages of Dry Ice Cleaning

1

Non-damaging to components

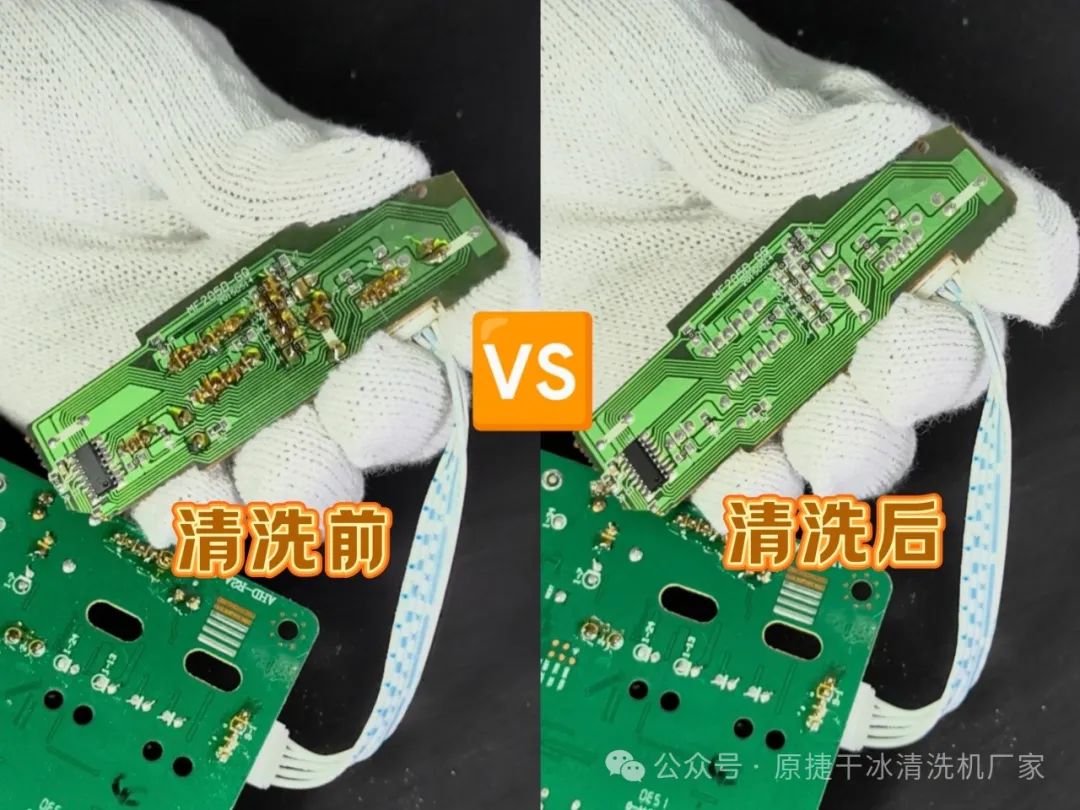

Dry ice particles are soft and non-conductive, avoiding mechanical scratches or electrostatic discharge, making them especially suitable for FPC flexible circuit boards and high-density PCBAs.

2

Deep cleaning with no dead angles

Particles can penetrate into hidden areas such as CPU slots and solder pad gaps, thoroughly removing flux residue, solder dross, dust, etc.

3

Environmentally friendly and safe

No chemical reagents are needed, no waste liquid is discharged, reducing workshop odors and fire risks.

4

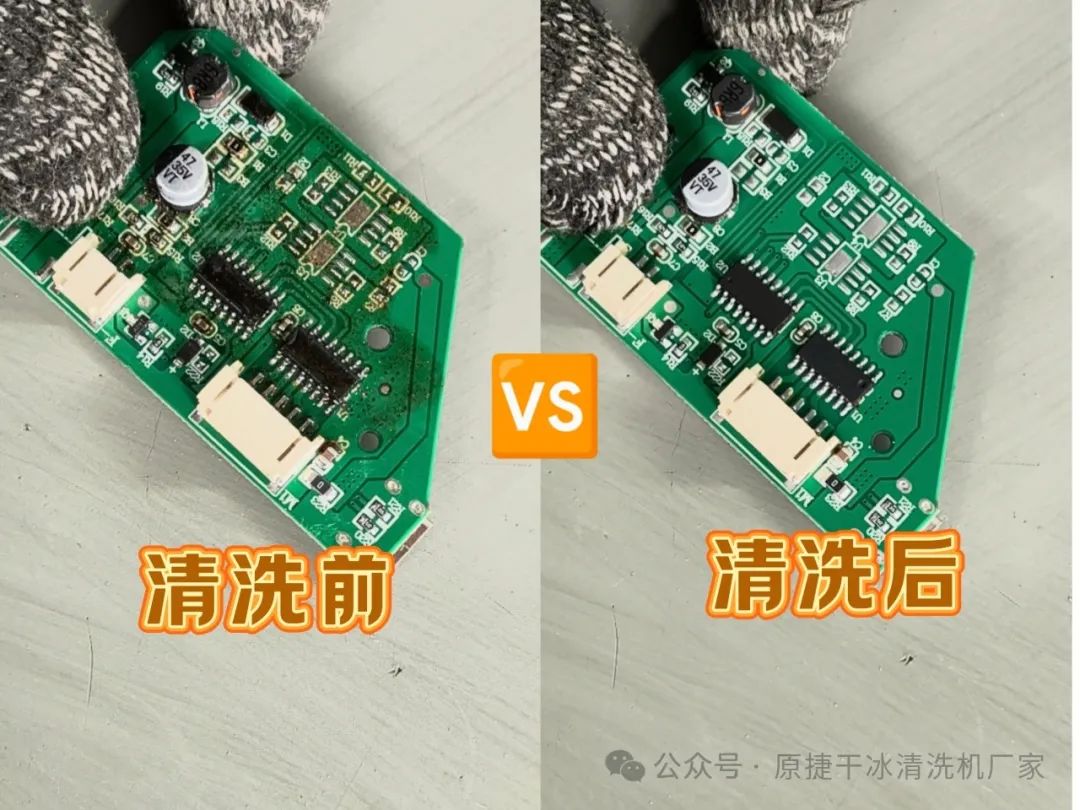

Efficient and energy-savingCleaning speed is 5-10 times that of manual cleaning, eliminating the drying step after water washing, saving time costs.

5

Adaptable to multiple scenarios

Can clean PCB hard boards, FPC soft boards, PCBA soldering boards, and even refurbish old circuit boards.

What situations are suitable for dry ice cleaning?

✅ Residual flux after new board production✅ Accumulation of dust and grease on old boards✅ Residual solder balls and rosin after soldering✅ Dense circuits that are difficult to reach manually

Professional equipment is key

Dry ice cleaning is currently the safest and most efficient cleaning solution for circuit boards

Dry ice cleaning is a fast, effective, safe, and environmentally friendly cleaning method that can help circuit board manufacturers improve production efficiency and quality!