Click on the top “Technical Training“, and select “Pin Public Account”

130,000+ industrial control professionals follow this WeChat platform: Technical sharing, learning exchange, industrial control videos

To make the display on our touch screen more intuitive, we usually need to implement some animation functions on the touch screen. There are two common types of animation functions: one is linear motion, such as moving an object to the left or upward. The other is rotational movement, such as the rotation of a fan. So how do we achieve these two functions on our Siemens touch screen?

Let’s first discuss the implementation of linear motion functionality. For example, if I want to move an object from left to right on the touch screen, how should I implement it?

First, we need to establish a variable, let’s say VW0. This variable is used to represent the movement of the object, meaning that the movement of the cart will depend on the changing value of this variable. We choose the data type of the variable as “INT”.

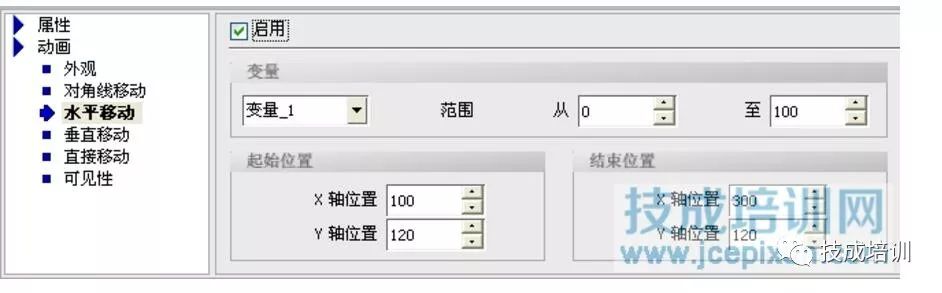

Second, select the object that needs to move and double-click. In its property dialog, there is an option for animation functionality, which includes several linear movement options. As shown in the figure:

For example, if we choose horizontal movement here, we need to enable the corresponding variable. The variable enabled here is the one we mentioned in the first point, which is used to represent the movement of the object, VW0. After setting up the associated variable, we then set the movement distance and the corresponding coordinate axis. Once these are established, all we need to do is write a program in the PLC that changes the value of VW0 within the set range, and this will achieve the effect of linear movement of the object.

Source: Technical Training Network

Feel free to share this with your friends!

Click Read the Original to learn about electrical engineering, PLCs, frequency servos, CNC robots, and more.