Click on the “Ji Cheng Training” above to select “Pin to Top Public Account”

150,000+ industrial control professionals follow this WeChat platform: technical sharing, learning exchange, industrial control videos

Basic knowledge of human-machine interface is essential for beginners. The product consists of hardware and software. The hardware includes the processor, display unit, input unit, communication interface, data storage unit, etc. HMI software is generally divided into two parts: the system software running on HMI hardware and the screen configuration software running on a PC with Windows operating system. This article provides a detailed introduction to the 10 key concepts of human-machine interfaces.

Human-Machine Interface (HMI)

Common terms: touch screen, HMI, human-machine interface

(I) Basic Functions and Selection Criteria of HMI Products

(1) Basic Functions:

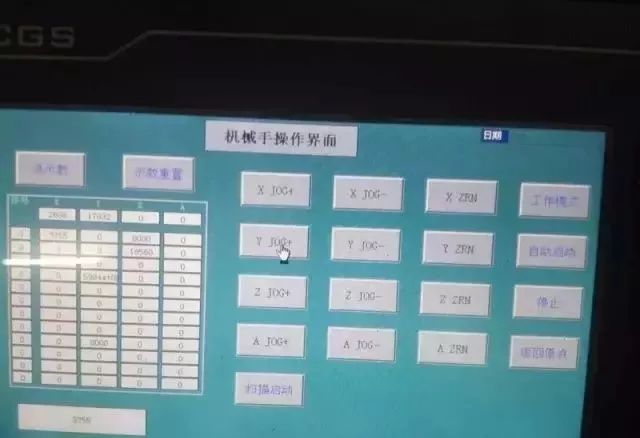

Display of device operating status, such as indicator lights, buttons, text, graphics, curves, etc.;

Data and text input operations, printing output;

Storage of production recipes, recording of device production data;

Simple logic and numerical calculations;

Can connect to various industrial control devices for networking.

(2) Selection Criteria:

Screen size and color, resolution;

Processor speed performance of the HMI;

Input method – touch screen or membrane keyboard;

Screen storage capacity – measured in bytes or bits;

Types and numbers of communication ports, whether it supports printing functions, etc.

(3) Product Classification:

Entry-level products: membrane keyboard input, typically with a display size of less than six inches

Mid-level products: touch screen input, typically with a display size greater than six inches

High-end products: computer input, typically with a display size greater than ten inches

(II) General Steps for Using HMI

(1) Clarify the monitoring task requirements and select the appropriate HMI product;

(2) Use screen configuration software on a PC to edit the “project file”;

(3) Test and save the edited “project file”;

(4) Connect the PC to the HMI hardware and download the “project file” to the HMI;

(5) Connect the HMI to the industrial controller (such as PLC, instruments, etc.) to achieve human-machine interaction.

(III) What is the difference between HMI and the commonly referred to “touch screen”?

In a strict sense, there is an essential difference between the two. The “touch screen” is merely a hardware component that may be used in human-machine interface products, serving as a replacement for some functions of a mouse and keyboard, installed in front of the display.

HMI products are a type of human-computer interaction device that includes both hardware and software. In industry, people often refer to human-machine interface products with touch input functionality as “touch screens,” but this is not scientifically accurate.

(IV) What is the difference between HMI and configuration software?

HMI products, often referred to as “touch screens,” include HMI hardware and corresponding specialized screen configuration software. Generally, different manufacturers’ HMI hardware uses different screen configuration software, with PLC as the main type of connected device.

Configuration software is a general tool software product that runs on a PC hardware platform and Windows operating system, and can also be combined with a PC or industrial computer to form HMI products; the general configuration software supports a wide variety of devices, such as various PLCs, PC boards, instruments, frequency converters, modules, etc. Moreover, due to the powerful performance of PC hardware platforms (mainly reflected in speed and storage capacity), the functionality of general configuration software is also much stronger, suitable for large monitoring systems.

(V) Do HMI products have an operating system?

Every human-machine interface product has a system software component that runs on the HMI’s processor, supporting multitasking capabilities, and the processor must have a small operating system to manage the operation of the system software. High-performance HMI products based on tablet computers generally use common embedded operating systems like WinCE and Linux.

(VI) Can HMI only connect to PLCs?

This is not the case. HMI products were developed to solve human-machine interaction issues with PLCs, but with the advancement of computer technology and digital circuit technology, many industrial control devices now have serial communication capabilities. Therefore, any industrial control device with serial communication capabilities, such as frequency converters, DC speed controllers, temperature control instruments, data acquisition modules, etc., can connect to human-machine interface products to achieve human-machine interaction functionality.

(VII) Can HMI products only connect to other devices through standard serial communication ports?

This is not the case. With the development of computer and digital circuit technology, the interface capabilities of human-machine interface products have become increasingly strong. In addition to traditional serial (RS232, RS422/RS485) communication interfaces, many HMI products now feature Ethernet, parallel, USB ports, etc., allowing them to connect with industrial control devices that also have these interfaces for human-machine interaction.

(VIII) Can devices with communication capabilities always connect to HMI products?

This should be the case. General human-machine interface products provide a large number of commonly used device communication driver programs for selection. Generally, as long as the corresponding communication driver program is selected in the screen configuration software of the HMI, the communication connection between the HMI and the device can be completed. If the selected HMI product’s configuration software does not have the communication driver program for the device to be connected, the user can inform the HMI product manufacturer of the communication port type and protocol content of the device to have the HMI manufacturer compile the communication driver program for that device.

(IX) Can a PC with a display communicate directly with a PLC to complete HMI functions?

Of course, it can. However, the PC must also compile corresponding configuration software to enable it to become a true HMI product.

(X) What is the future development trend of human-machine interfaces?

With the development of digital circuits and computer technology, the functional classification of future human-machine interface products into high, medium, and low will become less distinct, and the functionality of HMIs will become increasingly rich; HMI products with screen sizes above 5.7 inches will all be color displays, and the lifespan of screens will also be longer.

Due to the reduction in computer hardware costs, HMI products will primarily consist of high-end products based on tablet PCs, as these high-end products have significant advantages in processor speed, storage capacity, types and numbers of communication interfaces, networking capabilities, and software resource sharing, which is the future direction of HMI product development. Of course, small-sized (display size less than 5.7 inches) HMI products, due to their advantages in volume and price, will see widespread application in human-machine interaction for small machinery as their functionality continues to enhance (e.g., adding I/O functionality).

Some industries, such as machine tools, textile machinery, and electronic equipment, have developed for several decades in China and are relatively mature industries. In the long run, these industries still have a demand for equipment upgrades. During this upgrade process, some smaller manufacturers that have been using low-end products will indeed be eliminated, but many enterprises will redefine their needs during equipment updates, seeking suppliers that can meet their development plans and help them improve their productivity.

In light of this demand, future changes in human-machine interfaces will involve changes in shape, concepts, and application scenarios, leading to successive revolutions in the core technology of industrial control computers. Overall, the future development trend of human-machine interfaces is characterized by six modernizations: platform integration, brand localization, intelligent devices, fashionable interfaces, network communication, and energy conservation and environmental protection.

Have you shared today?

Click Read the Original to learn about electrical engineering, PLC, variable frequency servo, CNC robots, and more.