PLCs, inverters, and human-machine interfaces (HMIs) are essential devices in modern industrial automation control. Their applications have made factory production and manufacturing processes more automated, efficient, precise, and controllable, greatly advancing the automation process of China’s manufacturing industry and contributing significantly to the country’s modernization efforts.

A touch screen is a digital input-output device with touch display functionality, also known as a human-machine interface (HMI). When the touch screen is connected to a PLC, it can operate the PLC and monitor the working status of some internal soft components of the PLC in real-time on the touch screen. To operate and monitor the PLC using the touch screen, specific configuration software must be used on a computer to create (also known as configuration) the corresponding operation and monitoring screen projects, which are then downloaded to the touch screen.

Today, I would like to introduce a book titled Practical Manual for PLCs, Inverters, and HMIs (Siemens Edition). This book covers Siemens PLCs, inverters, and HMI configuration technology, including fundamental PLC concepts and practical entry into Siemens PLCs, an introduction to the Siemens S7-200 SMART PLC, usage of S7-200 SMART PLC programming software, application of basic instructions with examples, usage of sequence control instructions with examples, usage of functional instructions with examples, PLC communication, usage of Siemens inverters, inverter application circuits, comprehensive application of PLCs and inverters, introduction to Siemens touch screens, quick start with Siemens WinCC configuration software, usage of common objects in WinCC software, and practical control of PLCs using Siemens touch screens.

Click the image to purchase

Book Features

Preface

Chapter 1: PLC Basics and Practical Entry into Siemens PLCs

1.1 What is PLC

1.1.1 PLC Control vs Relay Control

1.2 Types and Characteristics of PLCs

1.2.1 Types of PLCs

1.2.2 Characteristics of PLCs

1.3 Composition and Working Principle of PLCs

1.3.1 PLC Composition Diagram

1.3.2 CPU and Memory

1.3.3 Input Interface Circuit

1.3.4 Output Interface Circuit

1.3.5 Communication Interfaces, Expansion Interfaces, and Power Supply

1.3.6 Working Modes of PLCs

1.3.7 Example of PLC Control Circuit’s Software and Hardware Working Process

1.4 PLC Programming Languages

1.4.1 Ladder Diagram

1.4.2 Function Block Diagram

1.4.3 Instruction Statement Table

1.5 Development Example of Siemens PLC Controlling Two Lights

1.5.1 General Process of PLC Application System Development

1.5.2 Control Requirements of the System

1.5.3 Selecting PLC Model and Determining Input/Output Devices and I/O Terminals

1.5.4 Drawing Circuit Diagram for Controlling Two Lights (See Figure 1-16)

1.5.5 Writing PLC Program with Programming Software

1.5.6 DC24V Power Adapter and Power Line

1.5.7 Connecting Computer and PLC with Programming Cable

1.5.8 Downloading Program to PLC

1.5.9 Simulation Debugging

1.5.10 Actual Wiring

1.5.11 Practical Operation Testing

Chapter 2: Introduction to Siemens S7-200 SMART PLC

2.1 Introduction to PLC Hardware

2.1.1 Two Types of CPU Modules

2.1.2 Description of CPU Module Panel Components

2.1.3 Wiring of CPU Module

2.1.4 Installation and Usage of Signal Board and Address Allocation

2.1.5 Common Modules and Ordering Numbers for S7-200 SMART PLC

2.2 Soft Components of PLC

2.2.1 Input and Output Relays

2.2.2 Auxiliary Relays, Special Auxiliary Relays, and Status Relays

2.2.3 Timers, Counters, and High-Speed Counters

2.2.4 Accumulators, Variable Memory, and Local Variable Memory

2.2.5 Analog Input and Output Registers

Chapter 3: Using S7-200 SMART PLC Programming Software

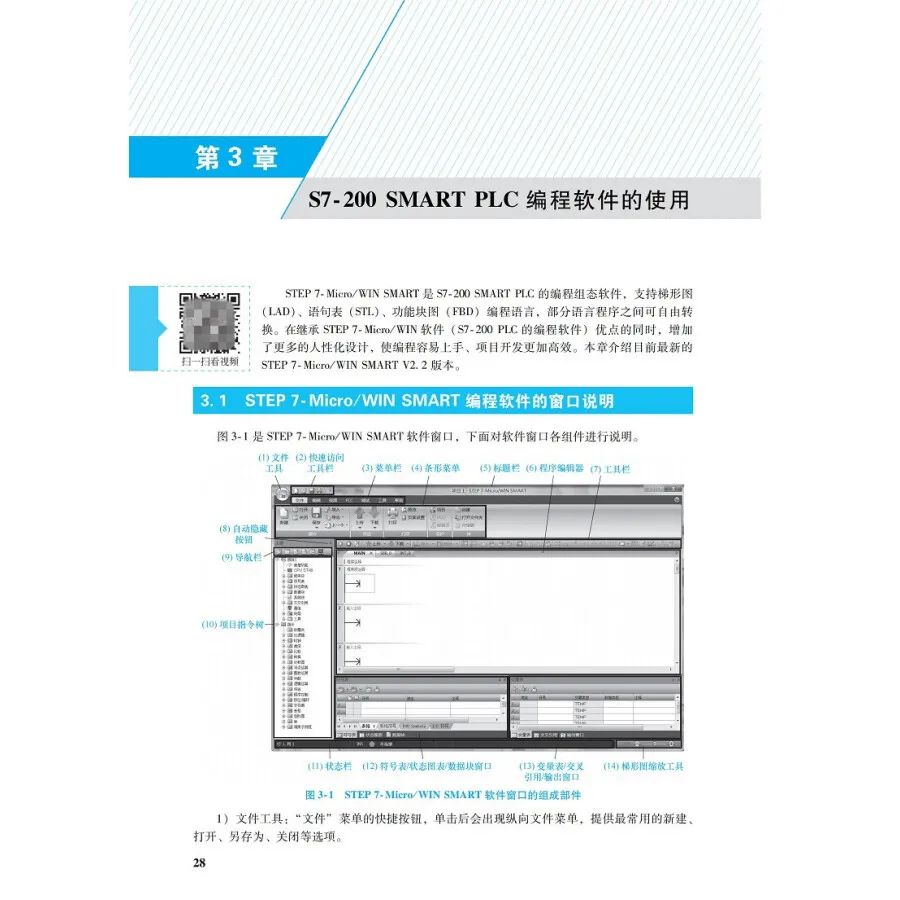

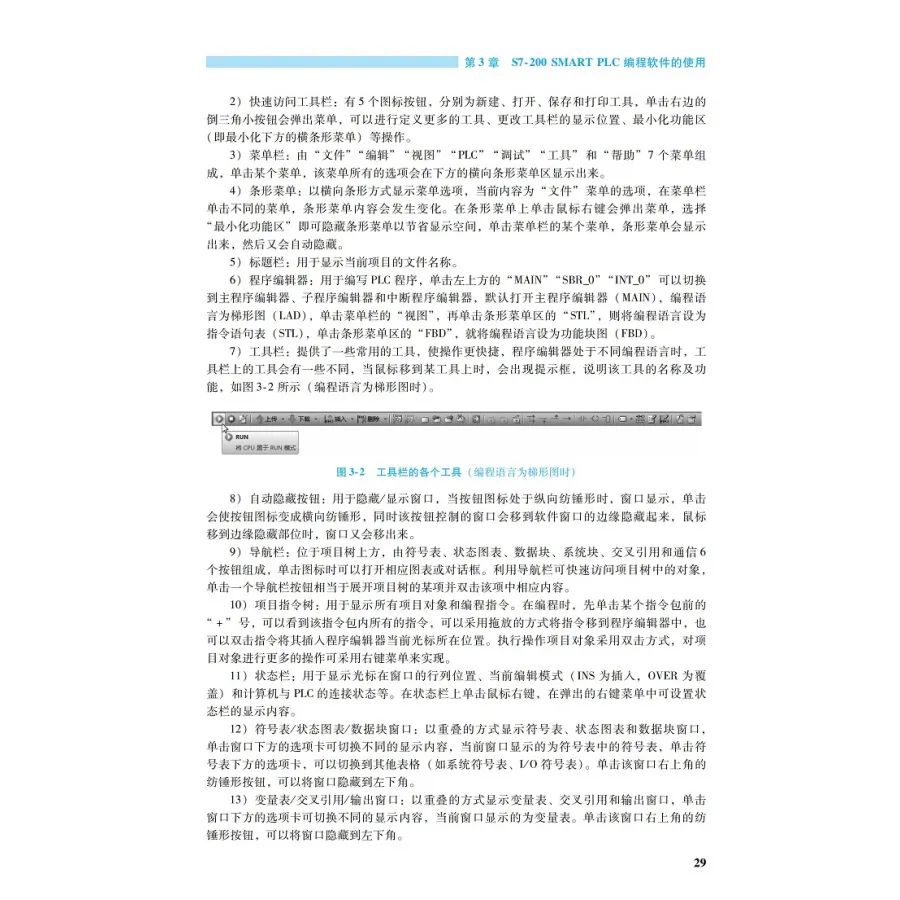

3.1 Description of STEP7-Micro/WIN SMART Programming Software Window

3.2 Writing and Downloading Programs

3.2.1 Creating and Saving Projects

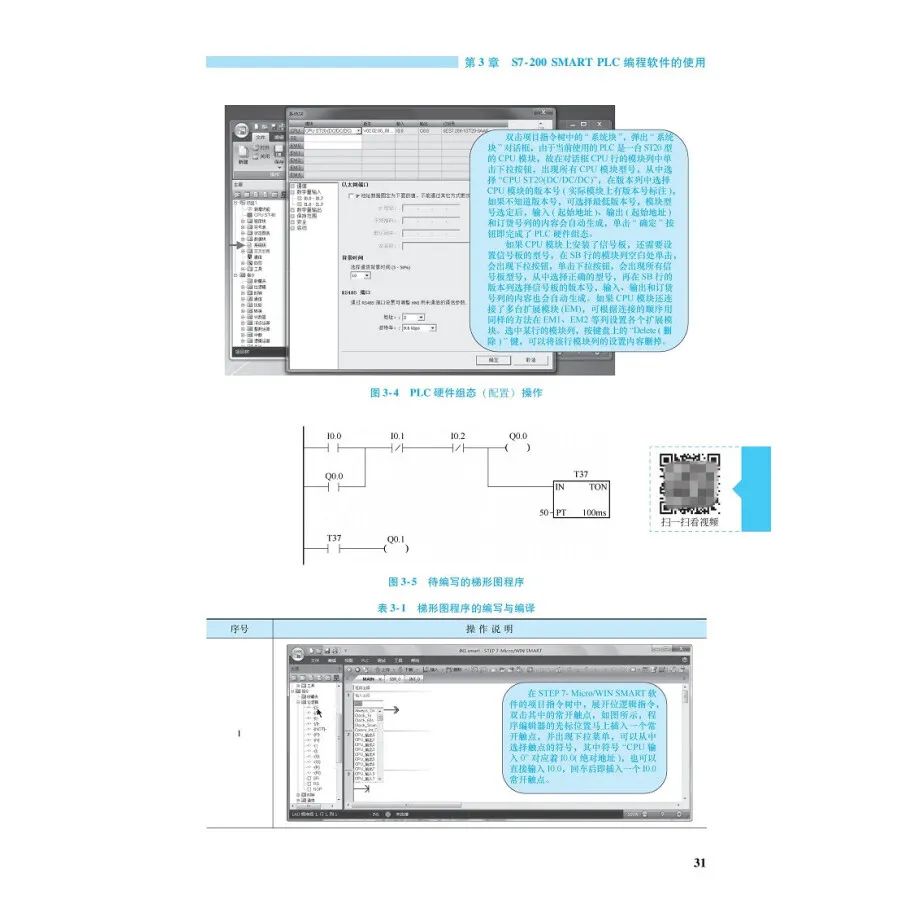

3.2.2 PLC Hardware Configuration

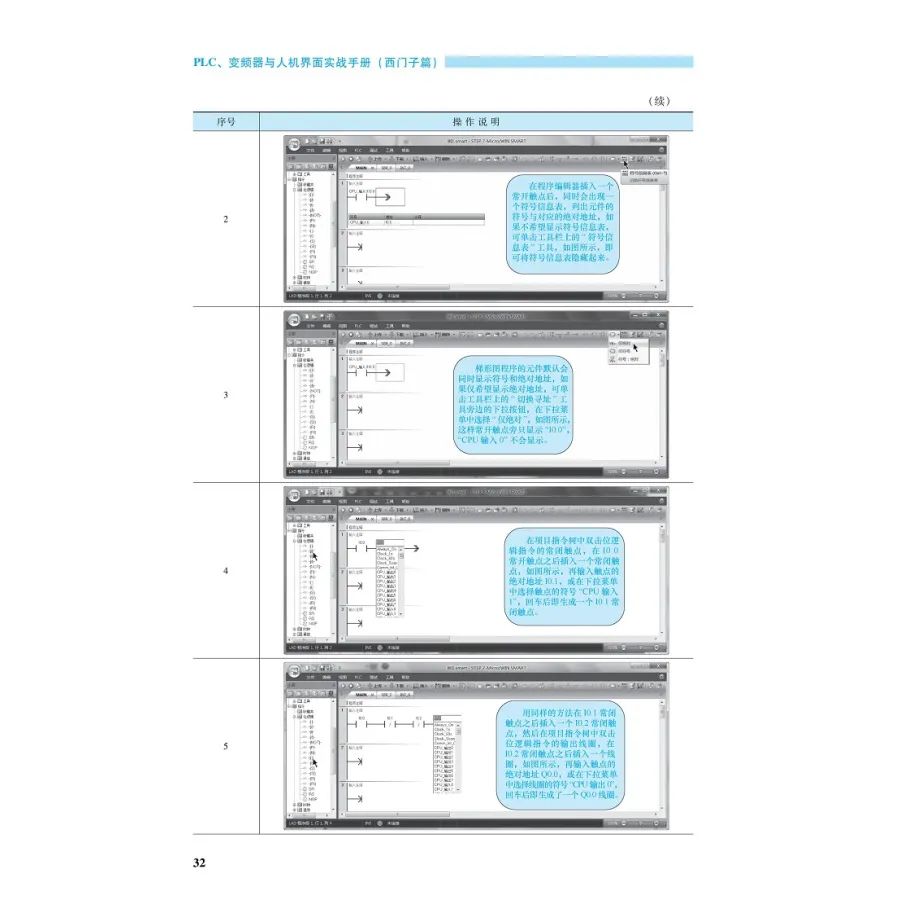

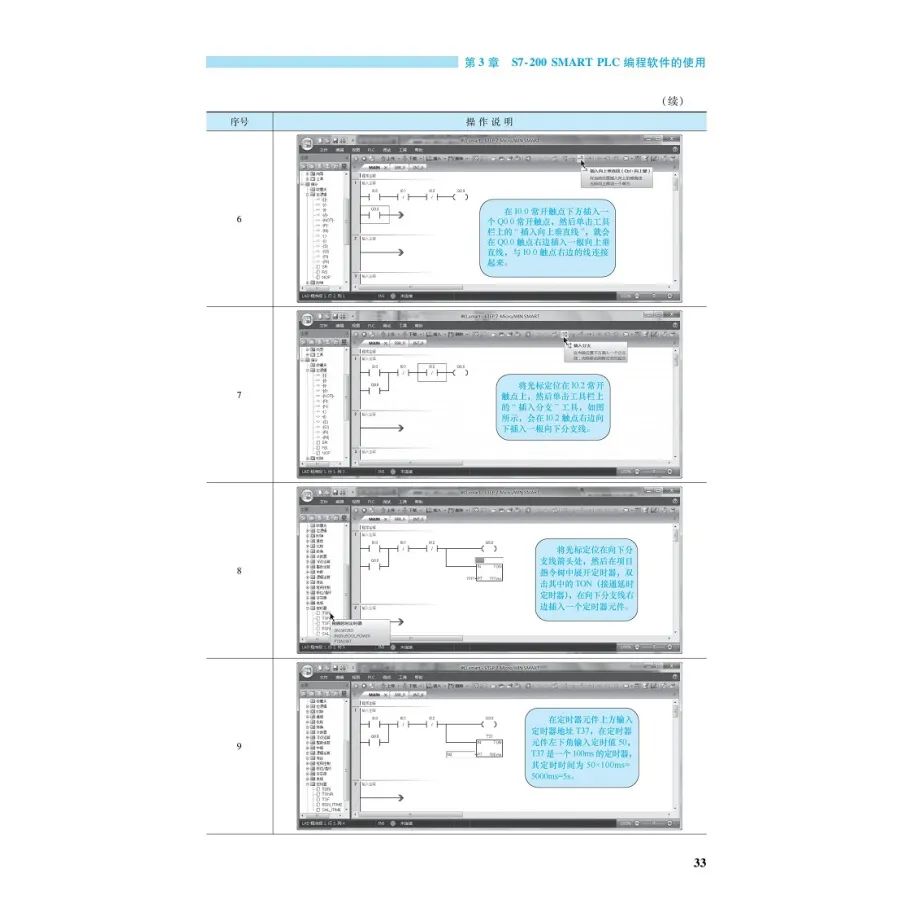

3.2.3 Writing and Compiling Programs

3.2.4 Connecting PLC and Computer and Communication Settings

3.3 Editing and Commenting Programs

3.3.1 Editing Programs

3.3.2 Commenting Programs

3.4 Monitoring and Debugging Programs

3.4.1 Monitoring and Debugging Programs with Ladder Diagram

3.4.2 Monitoring and Debugging Programs with State Chart Tables and Trend Charts

3.4.3 Monitoring and Debugging Programs with State Chart Trends

3.5 Object Settings, Hardware Configuration, and Data Copying

3.5.1 Settings of Common Objects

3.5.2 Hardware Configuration

3.5.3 Backing Up, Copying Programs, and Refreshing Firmware with Storage Cards

Chapter 4: Using Basic Instructions with Examples

4.1 Bit Logic Instructions

4.1.1 Contact Instructions

4.1.2 Coil Instructions

4.1.3 Immediate Instructions

4.1.4 RS Trigger Instructions

4.1.5 No Operation Instructions

4.2 Timers

4.2.1 On Delay Timer

4.2.2 Off Delay Timer

4.2.3 Memory On Delay Timer

4.3 Counters

4.3.1 Incrementing Counter

4.3.2 Decrementing Counter

4.3.3 Increment/Decrement Counter

4.4 Common Basic Control Circuits and Ladder Diagrams

4.4.1 Start, Self-locking, and Stop Control Circuits and Ladder Diagrams

4.4.2 Forward and Reverse Interlock Control Circuits and Ladder Diagrams

4.4.3 Multi-location Control Circuits and Ladder Diagrams

4.4.4 Timer Control Circuits and Ladder Diagrams

4.4.5 Long Timer Control Circuits and Ladder Diagrams

4.4.6 Multiple Output Control Circuits and Ladder Diagrams

4.4.7 Overload Alarm Control Circuits and Ladder Diagrams

4.4.8 Flashing Control Circuits and Ladder Diagrams

4.5 Example of Siemens PLC Control of a Fountain

4.5.1 System Control Requirements

4.5.2 I/O Terminals and Input/Output Devices

4.5.3 PLC Control Circuit

4.5.4 PLC Control Program and Detailed Explanation

4.6 Example of Siemens PLC Control of Traffic Lights

4.6.1 System Control Requirements

4.6.2 I/O Terminals and Input/Output Devices

4.6.3 PLC Control Circuit

4.6.4 PLC Control Program and Detailed Explanation

4.7 Example of Siemens PLC Control of Multi-level Conveyors

4.7.1 System Control Requirements

4.7.2 I/O Terminals and Input/Output Devices

4.7.3 PLC Control Circuit

4.7.4 PLC Control Program and Detailed Explanation

4.8 Example of Siemens PLC Control of Automatic Garage Doors

4.8.1 System Control Requirements

4.8.2 I/O Terminals and Input/Output Devices

4.8.3 PLC Control Circuit

4.8.4 PLC Control Program and Detailed Explanation

Chapter 5: Using Sequence Control Instructions with Examples

5.1 Sequence Control and State Transition Diagrams

5.2 Sequence Control Instructions

5.2.1 Instruction Names and Functions

5.2.2 Examples of Instruction Usage

5.2.3 Notes on Instruction Usage

5.3 Several Methods of Sequence Control

5.3.1 Selective Branching Method

5.3.2 Parallel Branching Method

5.4 Example of Siemens PLC Control of a Liquid Mixing Device

5.4.1 System Control Requirements

5.4.2 I/O Terminals and Input/Output Devices

5.4.3 PLC Control Circuit

5.4.4 PLC Control Program and Detailed Explanation

5.5 Example of Siemens PLC Control of a Simple Robotic Arm

5.5.1 System Control Requirements

5.5.2 I/O Terminals and Input/Output Devices

5.5.3 PLC Control Circuit

5.5.4 PLC Control Program and Detailed Explanation

5.6 Example of Siemens PLC Control of Sorting Large and Small Balls

5.6.1 System Control Requirements

5.6.2 I/O Terminals and Input/Output Devices

5.6.3 PLC Control Circuit

5.6.4 PLC Control Program and Detailed Explanation

Chapter 6: Using Functional Instructions with Examples

6.1 Data Types

6.1.1 Word Length

6.1.2 Data Types and Ranges

6.1.3 Programming Format for Constants

6.2 Transfer Instructions

6.2.1 Single Data Transfer Instructions

6.2.2 Byte Immediate Transfer Instructions

6.2.3 Data Block Transfer Instructions

6.2.4 Byte Swap Instructions

6.3 Comparison Instructions

6.3.1 Byte Contact Comparison Instructions

6.3.2 Integer Contact Comparison Instructions

6.3.3 Double Word Integer Contact Comparison Instructions

6.3.4 Real Number Contact Comparison Instructions

6.3.5 Examples of Comparison Instruction Applications

6.4 Mathematical Operation Instructions

6.4.1 Addition, Subtraction, Multiplication, and Division Instructions

6.4.2 Floating Point Function Operation Instructions

6.5 Logic Operation Instructions

6.5.1 Negation Instructions

6.5.2 AND Instructions

6.5.3 OR Instructions

6.5.4 XOR Instructions

6.6 Shift and Loop Instructions

6.6.1 Left and Right Shift Instructions

6.6.2 Circular Left and Right Shift Instructions

6.7 Conversion Instructions

6.7.1 Standard Conversion Instructions

6.7.2 ASCII Code Conversion Instructions

6.8 Table Instructions

6.8.1 Fill Table Instructions

6.8.2 Look-Up Table Instructions

6.9 Clock Instructions

6.9.1 Description of Clock Instructions

6.9.2 Examples of Clock Instruction Usage

6.10 Program Control Instructions

6.10.1 Jump and Label Instructions

6.10.2 Loop Instructions

6.10.3 End, Stop, and Reset Timer Instructions

6.11 Subroutines and Subroutine Instructions

6.11.1 Subroutines

6.11.2 Subroutine Instructions

6.12 Interrupt Events and Interrupt Instructions

6.12.1 Interrupt Events and Interrupt Priorities

6.12.2 Interrupt Instructions

Chapter 7: PLC Communication

7.1 Basic Knowledge of Communication

7.1.1 Communication Methods

7.1.2 Communication Transmission Media

7.2 PLC Ethernet Communication

7.2.1 Device Types for Ethernet Connection of S7-200 SMART PLC CPU Module

7.2.2 Setting IP Addresses

7.2.3 Ethernet Communication Instructions

7.2.4 Example of PLC Ethernet Communication

7.3 PLC RS-485/RS-232 Communication

7.3.1 RS-232C, RS-422A, and RS-485 Interface Circuit Structure

7.3.2 Pin Function Definitions for RS-485/RS-232

7.3.3 Getting Port Address Instructions and Setting Port Address Instructions

7.3.4 Sending and Receiving Instructions

Chapter 8: Using Siemens Inverters

8.1 Basic Structure and Principles of Inverters

8.1.1 Two Speed Control Methods for Asynchronous Motors

8.1.2 Structure and Principles of Two Types of Inverters

8.2 Structure and Wiring of Siemens MM440 Inverter

8.2.1 Shape and Model (Ordering Number) Meanings

8.2.2 Internal Structure and External Wiring Diagram

8.2.3 Wiring of External Terminals of Main Circuit

8.2.4 Typical Actual Wiring of Control Circuit External Terminals

8.2.5 Wiring and Parameter Settings for Digital Input Terminals

8.2.6 Wiring and Parameter Settings for Analog Input Terminals

8.2.7 Wiring and Parameter Settings for Digital Output Terminals

8.2.8 Wiring and Parameter Settings for Analog Output Terminals

8.3 Stopping, Braking, and Restarting Methods for Inverters

8.3.1 Motor Nameplate Data and Corresponding Parameters for Inverters

8.3.2 Stopping Methods for Inverters

8.3.3 Braking Methods for Inverters

8.3.4 Restarting Methods for Inverters

8.4 Operating and Debugging Inverters Using Panels and External Terminals

8.4.1 Operating and Debugging Inverters Using SDP and External Terminals

8.4.2 Operating and Debugging Inverters Using BOP

8.4.3 Operating and Debugging Inverters Using AOP

8.5 Parameter Debugging and Routine Operations of MM440 Inverter

8.5.1 Resetting All Parameters of the Inverter

8.5.2 Steps and Explanations for Quick Parameter Debugging Settings

8.5.3 Routine Operations of the Inverter

Chapter 9: Inverter Application Circuits

9.1 Inverter Circuit for Controlling Forward and Reverse Rotation and Speed Adjustment via Panel Keyboard

9.1.1 Control Requirements

9.1.2 Circuit and Operation Instructions

9.1.3 Parameter Settings

9.2 Inverter Circuit for Controlling Forward and Reverse Rotation and Speed Adjustment via Panel Potentiometer

9.2.1 Control Requirements

9.2.2 Circuit and Operation Instructions

9.2.3 Parameter Settings

9.3 Multi-speed Control of Inverters and Application Circuits

9.3.1 Three Methods for Multi-speed Control of Inverters

9.3.2 Application Circuits for Multi-speed Control of Inverters

9.4 PID Control Circuit for Inverters

9.4.1 Principles of PID Control

9.4.2 PID Related Parameters

9.4.3 PID Control of Constant Pressure Water Supply Inverter Circuit and Parameter Settings

Chapter 10: Comprehensive Application of PLCs and Inverters

10.1 PLC Control of Inverter Driven Motor with Delayed Forward and Reverse Rotation Circuit

10.1.1 Control Requirements

10.1.2 Allocation of PLC Input and Output Terminals

10.1.3 Circuit Wiring

10.1.4 Inverter Parameter Settings

10.1.5 PLC Control Program and Explanation

10.2 PLC Control of Inverter for Multi-speed Operation Circuit

10.2.1 Control Requirements

10.2.2 Allocation of PLC Input and Output Terminals

10.2.3 Circuit Wiring

10.2.4 Inverter Parameter Settings

10.2.5 PLC Control Program and Explanation

10.3 Application Example of PLC Controlling Inverter via USS Protocol Communication

10.3.1 Hardware Connection for S7-200 PLC and MM440 Inverter Serial Communication

10.3.2 USS Protocol

10.3.3 Installing USS Communication Library in S7-200 PLC Programming Software

10.3.4 USS Communication Instructions

10.3.5 Application Example of S7-200 PLC Controlling MM440 Inverter via USS Protocol Communication

Chapter 11: Introduction to Siemens Touch Screens

11.1 Basic Knowledge of Touch Screens

11.1.1 Basic Components

11.1.2 Working Principles

11.2 Introduction to Siemens Exciting Series Touch Screens

11.2.1 Features of SMARTLINE Touch Screens

11.2.2 Common Models and Shapes

11.2.3 Main Component Descriptions of Touch Screens

11.2.4 Technical Specifications

11.3 Connection of Touch Screens with Other Devices

11.3.1 Power Wiring for Touch Screens

11.3.2 Ethernet Connection of Touch Screens with Configuration Computers

11.3.3 Connection of Touch Screens with Siemens PLCs

11.3.4 Connection of Touch Screens with Mitsubishi, Schneider, and Omron PLCs

Chapter 12: Quick Start with Siemens WinCC Configuration Software

12.1 Installation of WinCC flexible SMART V3 Software

12.1.1 System Requirements

12.1.2 Software Download and Installation

12.2 Configuring a Simple Project with WinCC Software

12.2.1 Creating and Saving Projects

12.2.2 Configuring Variables

12.2.3 Configuring Screens

12.2.4 Simulated Running of Projects

Chapter 13: Usage of Common Objects in WinCC Software

13.1 Examples of Using IO Domains

13.1.1 Configuring Tasks

13.1.2 Configuring Processes

13.1.3 Running Tests

13.2 Examples of Using Buttons

13.2.1 Configuring Tasks

13.2.2 Configuring Processes

13.2.3 Running Tests

13.3 Examples of Using Variable Control Object Animations

13.3.1 Configuring Tasks

13.3.2 Configuring Processes

13.3.3 Running Tests

13.3.4 Simulation Debugging

13.4 Examples of Using Pointer Variables

13.4.1 Configuring Tasks

13.4.2 Configuring Processes

13.4.3 Running Tests

13.5 Examples of Using Switches and Drawing Tools

13.5.1 Configuring Tasks

13.5.2 Configuring Processes

13.5.3 Running Tests

13.6 Examples of Using Alarm Functions

13.6.1 Basic Knowledge of Alarms

13.6.2 Configuring Tasks

13.6.3 Configuring Processes

13.6.4 Running Tests

13.7 Examples of Using Bar Charts and Trend Charts

13.7.1 Configuring Tasks

13.7.2 Configuring Processes

13.7.3 Running Tests

13.8 Examples of Using Screen Switching

13.8.1 Creating Screens (See Table 13-10)

13.8.2 Setting Screen Switching Using Drag-and-Drop Button Generation

13.8.3 Implementing Specified Screen Switching Using Buttons with Screen Switching Functions (See Table 13-11)

13.8.4 Implementing Any Number Screen Switching Using Buttons with Screen Switching Functions

Chapter 14: Practical Control of PLCs by Siemens Touch Screens

14.1 Clarifying Requirements, Planning Variables and Circuits

14.1.1 Control Requirements

14.1.2 Selecting PLC and Touch Screen Models and Allocating Variables

14.1.3 Device Connections and Circuits

14.2 Writing and Downloading PLC Programs

14.2.1 Writing PLC Programs

14.2.2 Connecting PLC with Computer and Settings

14.2.3 Downloading and Uploading PLC Programs

14.3 Configuring and Downloading Touch Screen Project Items

14.3.1 Creating Touch Screen Project File

14.3.2 Configuring Touch Screen Connection with PLC

14.3.3 Configuring Variables

14.3.4 Configuring Indicator Lights

14.3.5 Configuring Buttons

14.3.6 Configuring Status Value Monitors

14.3.7 Configuring Instruction Texts

14.3.8 Downloading Projects to Touch Screens

14.3.9 Common Reasons and Solutions for Inability to Download Projects

14.3.10 Updating Touch Screen Versions Using ProSave Software

14.4 Operating and Monitoring Tests for Siemens Touch Screens Connected to PLCs

14.4.1 Hardware Connection and Communication Settings of Touch Screens Connected to PLCs via Network Cable

14.4.2 Hardware Connection and Communication Settings of Touch Screens Connected to PLCs via Serial Cable

14.4.3 Practical Operation Testing of Siemens Touch Screens Connected to PLCs

Source: Jinfen Mall

Welding + Welding Robot Operation Skills Fully Covered

Essential for Hardware Data Reference

Explaining CNC Machine Tool Fault Diagnosis and Repair with Examples