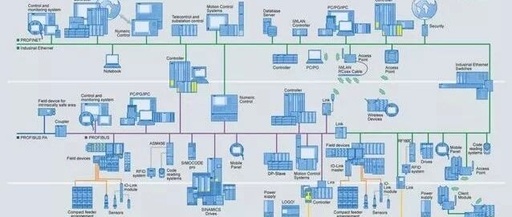

A Detailed Explanation of Siemens Industrial Communication Network Technologies from PTP, AS-I to PROFIBUS and Industrial Ethernet

↑ Click on the above “Smart Manufacturing Home” Follow us Introduction Hello everyone, I am Alic, a friend of the owner Xiaozhi~ Industrial communication is an unavoidable topic in our field control, and we have introduced many aspects before, such as redundant networks, VLAN, PROFINET, etc.~ The main content of this communication discussion includes: 01 … Read more