During the repair process of welding machines, we often encounter some difficult issues, and at this time, we will use the oscilloscope.

Case:NBC270Gas shielded welding with manual welding

The fault phenomenon is that the gun outputs gas and feeds wire normally, but does not melt the wire.

After excluding problems with the main control board, wire feeder, and gun, the issue lies with the inverter board. The measured values are normal, so we need to bring out our oscilloscope.

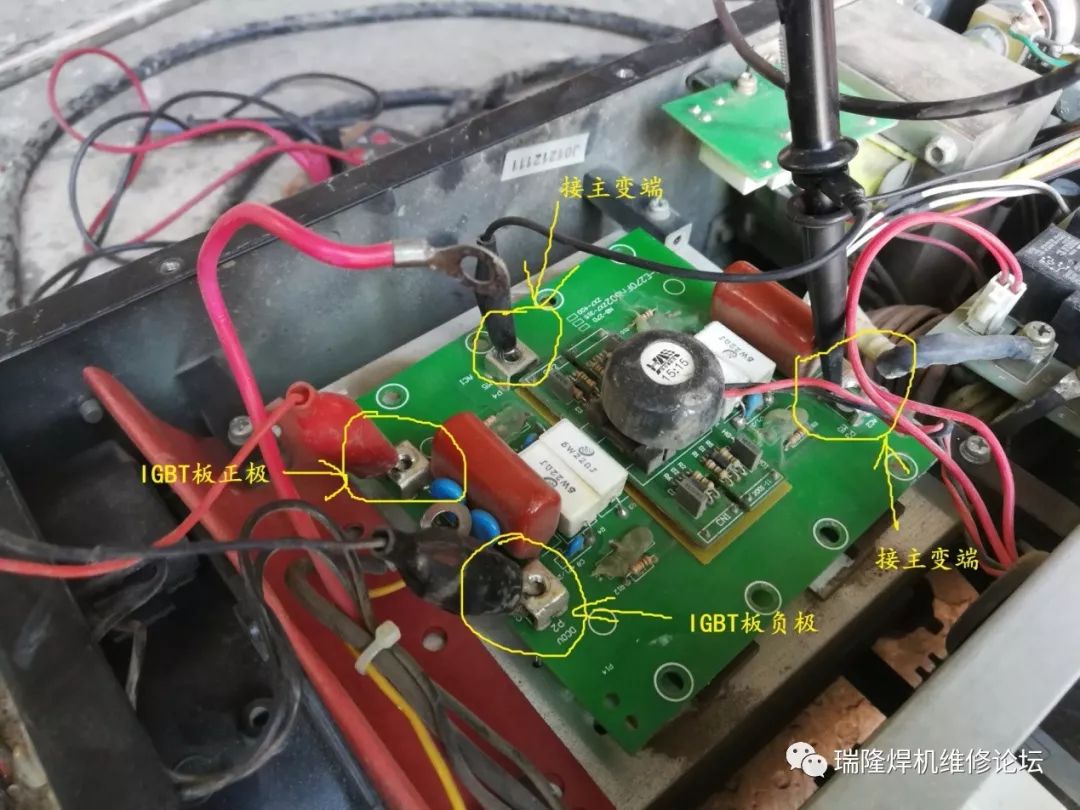

Supply aIGBTboard’s main power output terminal with a30VDC voltage, connecting the positive to theIGBTboard’s positive terminal and the negative to theIGBTboard’s negative terminal. Connect the oscilloscope to the two main transformer input terminals of theIGBTboard, turn on the welding machine, switch to manual welding, and observe the waveform on the oscilloscope.

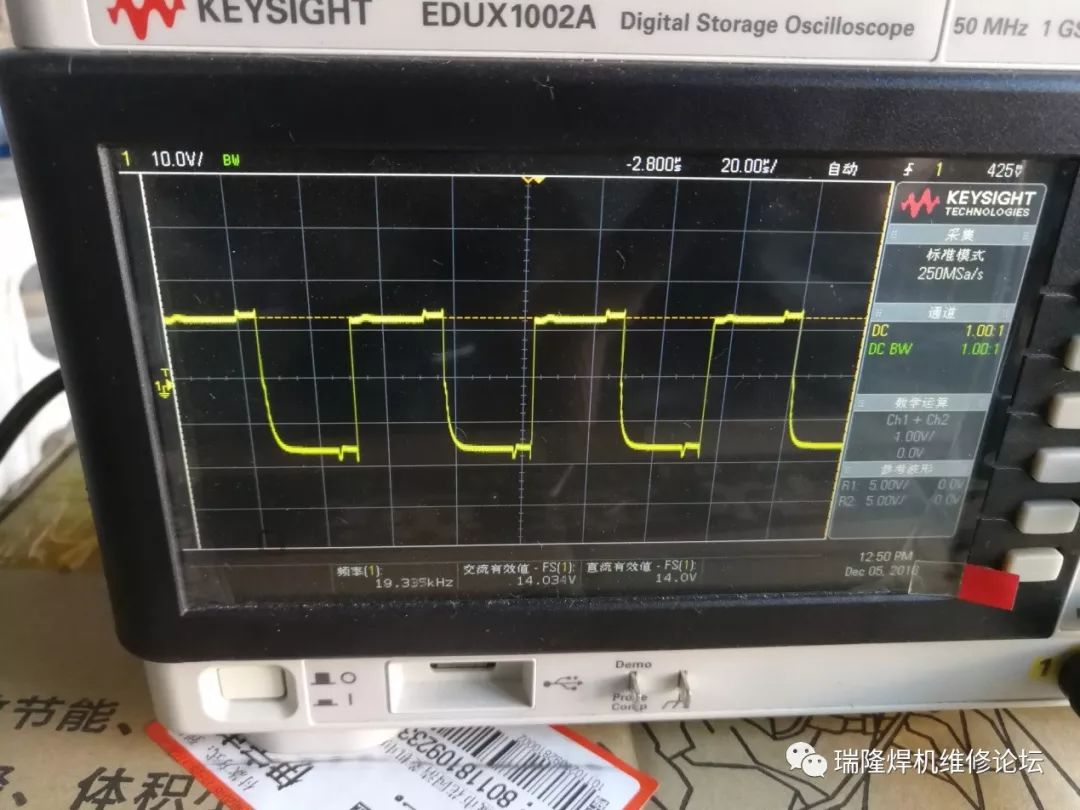

Under normal conditions, it should be a square wave. If the waveform is missing a corner, it indicates that one of the fourIGBTtransistors is faulty, but the measurements are normal, so all must be replaced. After replacement, we will check the waveform again.

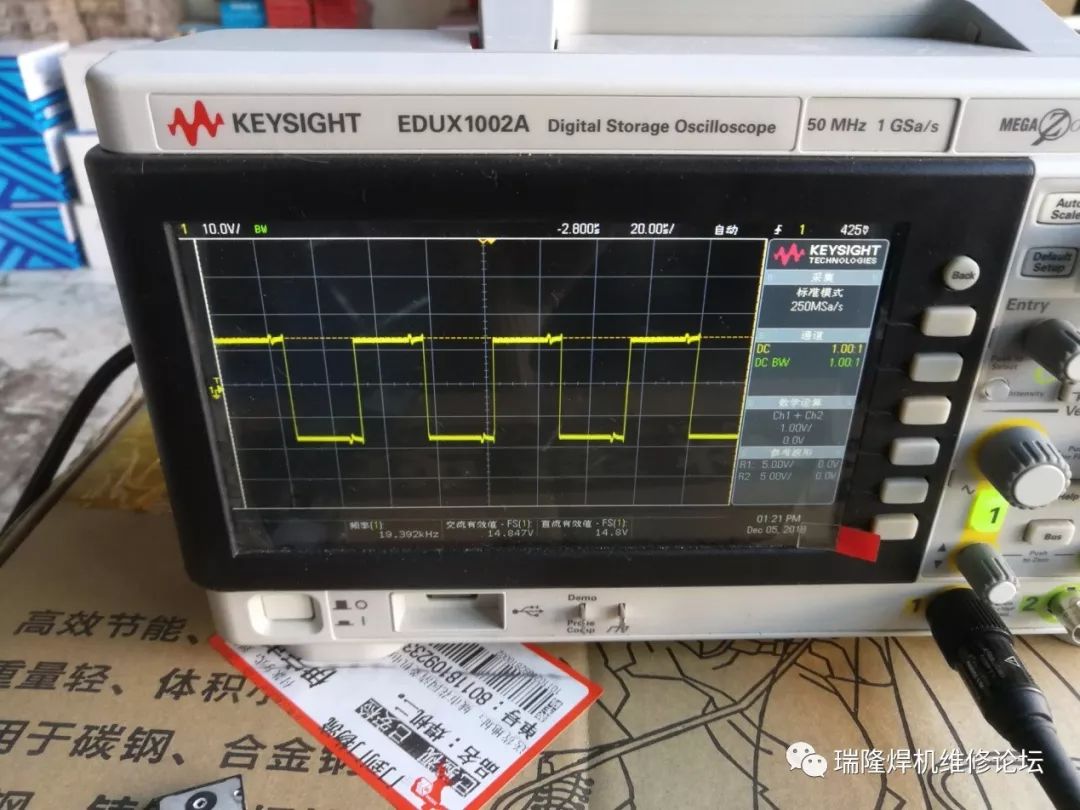

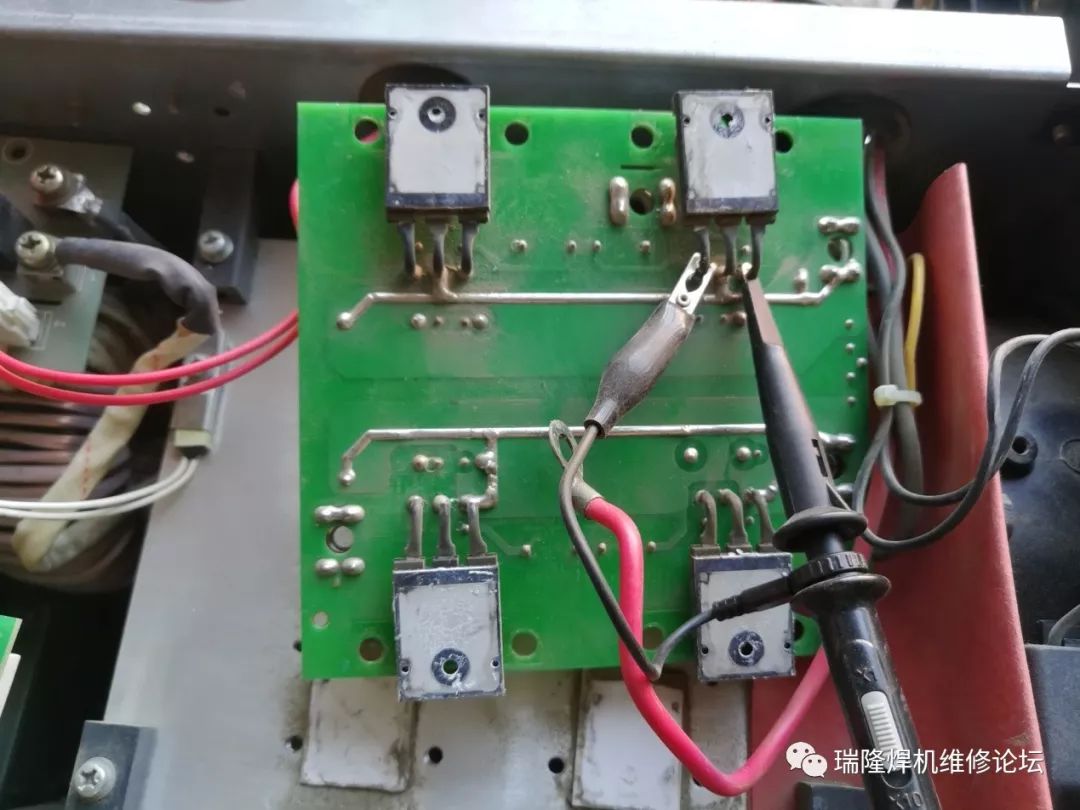

At this time, the waveform is normal, indicating that the problem has been resolved. Now let’s take a look at the IGBT drive waveform and measurement method. Remove the main power and main transformer connections on the inverter board, leaving only the drive lines,and connect the oscilloscope across theIGBTon both sides.

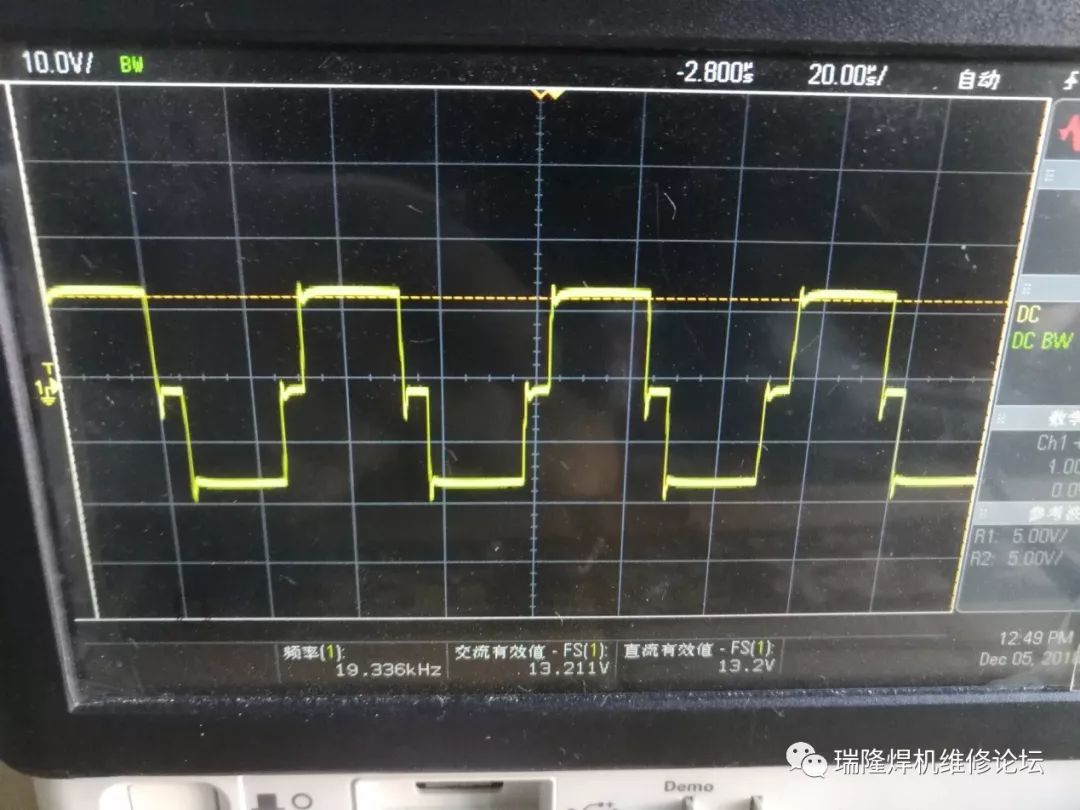

As shown in the above figure.

The IGBT drive waveform is shown in the above figure. From the oscilloscope, the frequency is19.336KHZand the AC value is13.2V. Most drive waveforms are as shown above, but there are exceptions with different waveforms, such as those from the Huto Dali machine and the Buwei machine.

Starting today, the public account will begin to integrate the business of Hebei Longya Welding. Longya Welding is a professional manufacturer of welding accessories, with main products including: quick connector series, welding torch cables, bare copper wires, control wires, integrated wire feeder lines, various gas shielded welding guns, argon arc welding guns, plasma cutting guns, etc. The company’s products use sufficient materials, advanced production processes, and high cost performance, which are well received by many welding machine manufacturers and wholesalers.

The welding and cutting accessories are relatively heavy, and most distributors ship via logistics. The shipping cost is determined based on the weight of the goods and the destination.If you need them, please long press to identify the QR code below to add me on WeChat18236924252.After confirming the price and shipping costs, scan the Longya company’s payment code for payment, and we will ship as soon as possible.

All products here are factory direct sales, eliminating all wholesale distribution links, allowing you to get the most favorable prices and meet everyone’s one-stop procurement needs. We welcome a wide range of welding machine wholesalers and distributors to contact us for consultation. Click the mini program below to learn more.