Today, I will share with you a practical case involving a water level control project using PLC, inverter, and touch screen. Let’s take a look at the whole process, which you can save for future reference!

● Project Description

● EM235 Module

● Project Implementation

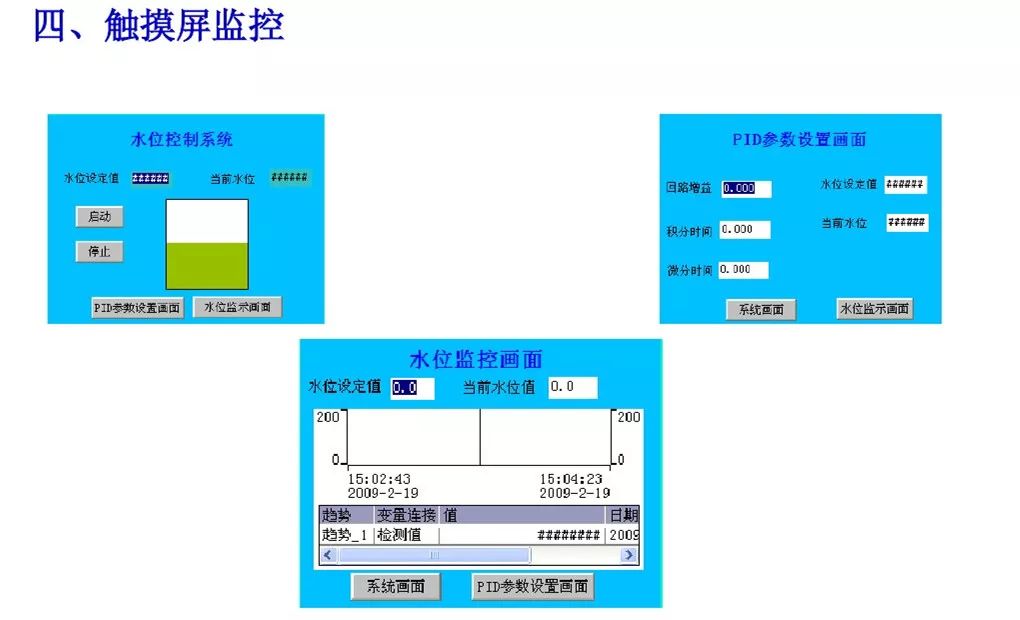

● Touch Screen Monitoring

1. Project Description

1. Control Requirements

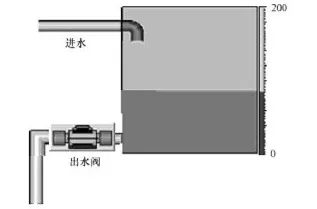

The water tank supplies water to external users, with an unstable water usage that varies from high to low. Water is pumped into the tank, and we need to maintain a constant water level control within a range of 0~200mm (the maximum value can be determined based on the height of the tank). For example, if the set water level is 100mm, regardless of the outflow, we must adjust the inflow to keep the water level at 100mm. If the outflow is low, the inflow should also be low; if the outflow is high, the inflow should also be high.

2. Control Strategy

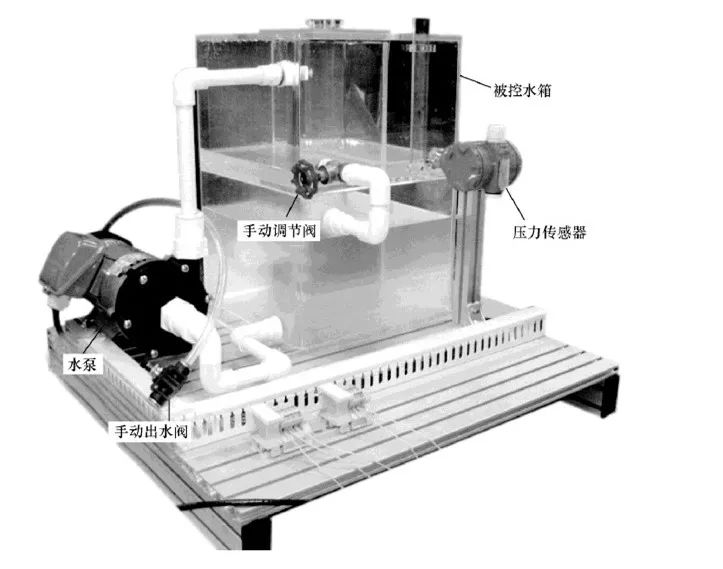

Since the liquid level height is proportional to the pressure at the bottom of the tank, we can use a pressure sensor to detect the pressure at the bottom of the tank, thus determining the liquid level height. The PD algorithm is used for automatic adjustment of the water level. The water level signal detected by the pressure sensor (4~20mA) is sent to the PLC. The PLC performs a PID calculation on the deviation between the set value and the detected value, and the calculation result is output to adjust the speed of the water pump motor, thereby adjusting the inflow. The speed of the water pump motor can be controlled by the inverter.

3. Component Selection

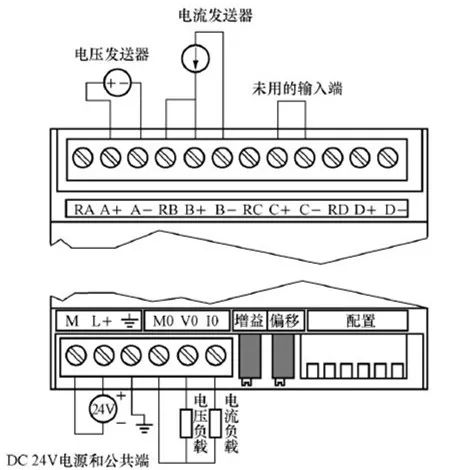

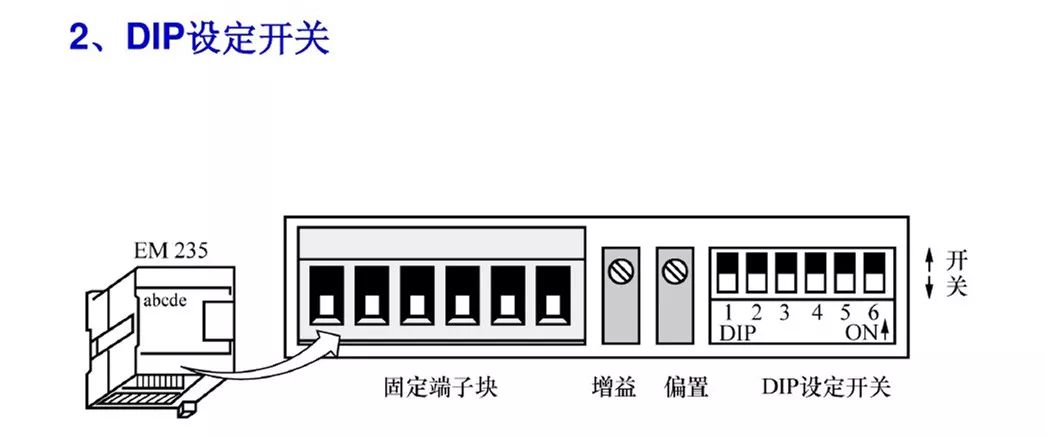

1) Selection of PLC and its Modules. The PLC can be selected as S7-200cPU224. To receive the analog signal from the pressure sensor and adjust the speed of the water pump motor, an EM235 analog input/output module is chosen.

2) Inverter Selection. To adjust the inflow, the Siemens G110 inverter is selected.

3) Touch Screen Selection. The Siemens TP170B human-machine interface touch screen is selected.

4) Water Tank Object Equipment, as shown in the figure below.

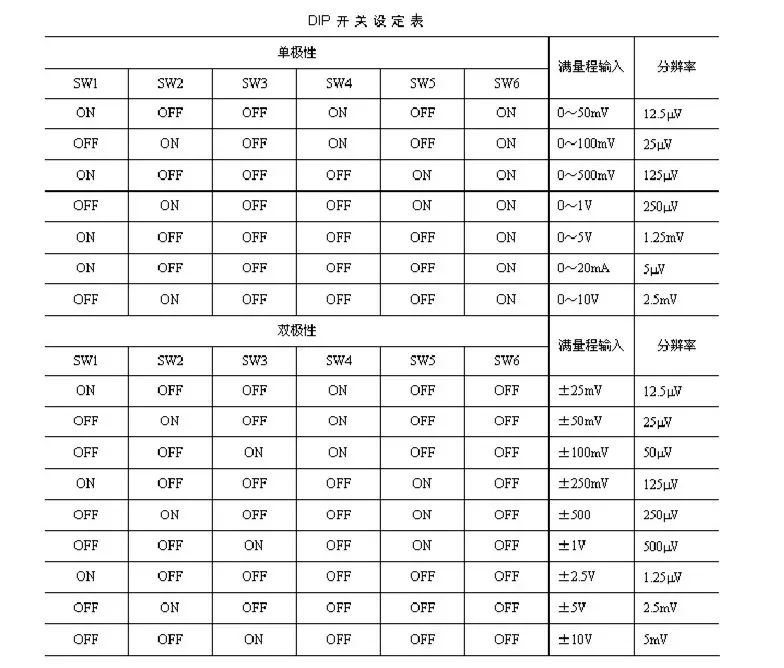

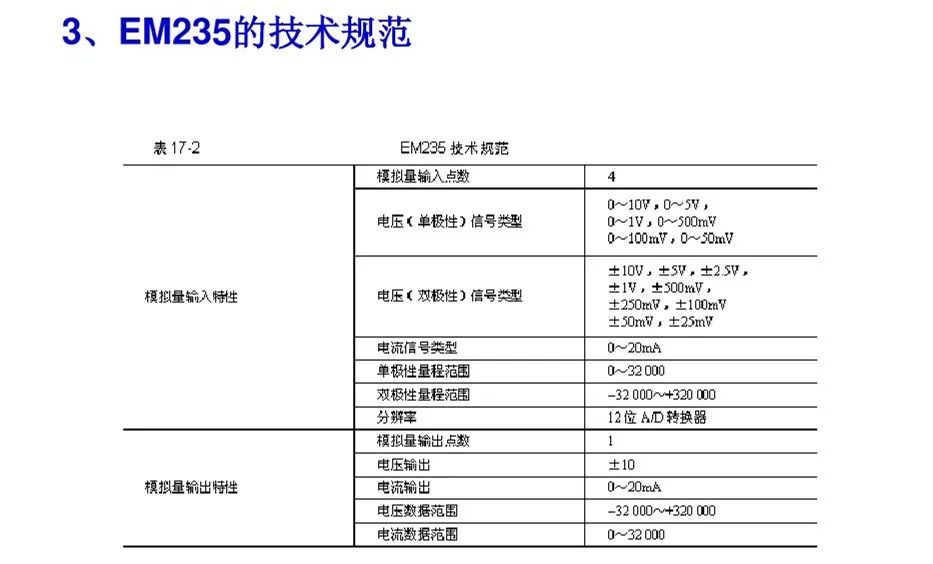

2. EM235 Module

Wiring and Terminals of EM235

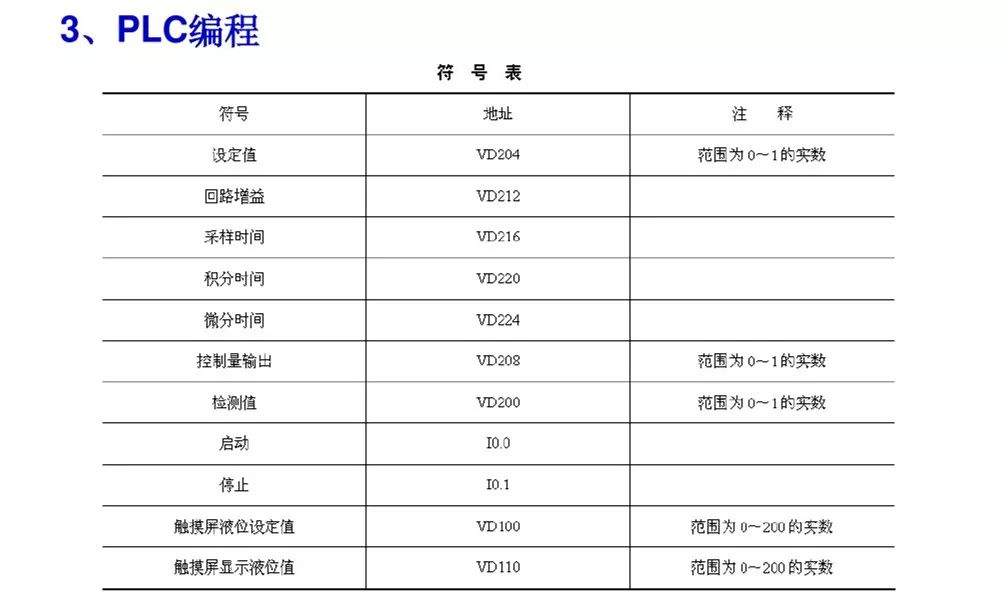

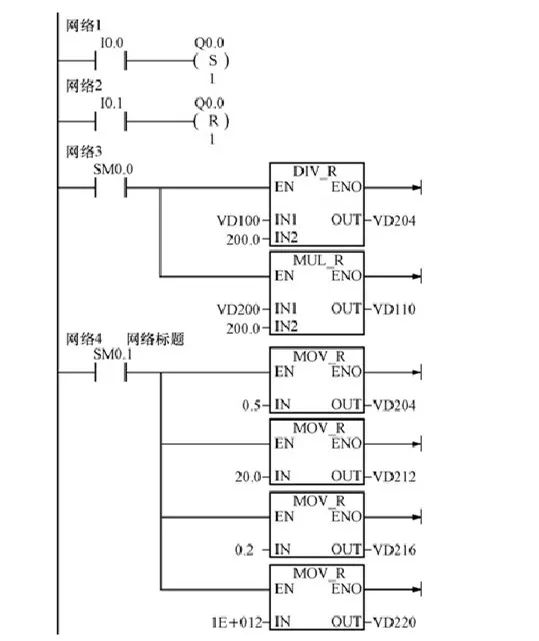

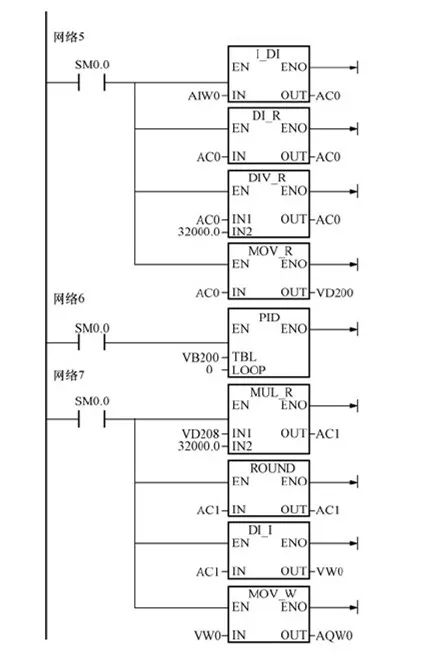

3. Project Implementation

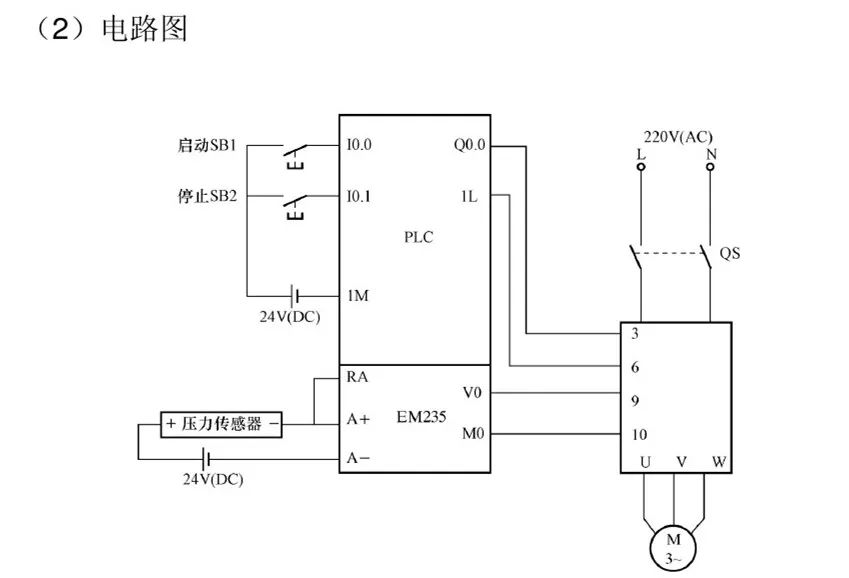

1. PLC IO Allocation and Circuit Diagram

PLC IO Allocation

Start Button, 10.0;

Stop Button, 10.1;

Q0.0, controls the operation of the water pump motor.

4. Touch Screen Monitoring

Source: Internet, please contact for deletion if there is any infringement.

Recommended Reading

Can You Learn PLC by Self-Study?

Click to view

Get Beginner PLC Learning Materials

Revealing the Real Salaries of Electricians, How Low Are They?

Click to view

Get Promotion and Salary Increase Secrets for Electricians