PCB Manual: Differences Between Via and Pad

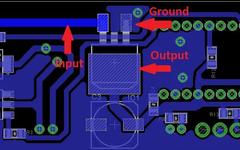

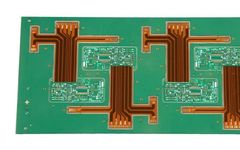

In PCB design, we often encounter the two technical terms “Via” and “Pad.” They each have distinct functions and uses. This article will detail the differences and roles of these two elements, hoping to assist everyone. 1. Via, also known as a via, is primarily used to achieve electrical connections between different layers. Depending on … Read more