The working principle of a circuit board is to use an insulating material to separate the surface copper foil conductive layer, allowing current to flow along a pre-designed route through various components to perform functions such as work, amplification, attenuation, modulation, demodulation, and encoding.

Figure 1: Circuit Board

The circuit board mainly consists of pads, vias, mounting holes, wires, components, connectors, and other elements. The main functions of each component are as follows:

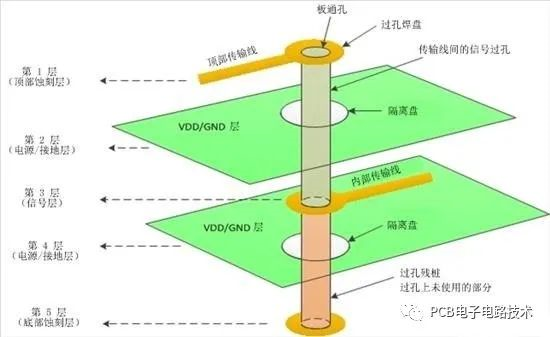

Pad: A metal hole used for soldering component pins.

Via: There are metal vias and non-metal vias, where metal vias are used to connect component pins between layers.

Mounting Hole: Used to fix the circuit board.

Wire: An electrical network copper film connecting component pins.

Connector: A component used to connect between circuit boards.

Filling: Copper plating used for ground networks, which can effectively reduce impedance.

Electrical Boundary: Used to determine the size of the circuit board; all components on the circuit board must not exceed this boundary.

Figure 2: Structure of Circuit Board Vias

Circuit boards can be classified into three main categories based on the number of layers: single-sided boards, double-sided boards, and multilayer boards.

Multilayer Board: Refers to a printed circuit board consisting of three or more conductive pattern layers and insulating materials laminated between them, with the conductive patterns interconnected as required. Multilayer circuit boards are products of the development of electronic information technology towards high speed, multifunctionality, large capacity, small size, thinness, and lightweight.

Single-sided Board: On the most basic PCB, components are concentrated on one side, while wires are concentrated on the other side. Since wires only appear on one side, this PCB is called a single-sided board. Single-sided boards are usually simple to manufacture and low in cost, but the downside is that they cannot be applied to overly complex products.

Double-sided Board: An extension of the single-sided board, used when single-layer wiring cannot meet the needs of electronic products. Both sides have copper coating and wiring, and connections can be made between the two layers through vias to form the required network connections.

Circuit boards can also be classified according to their characteristics into flexible boards (FPC), rigid boards (PCB), and rigid-flex boards (FPCB).

Figure 3: Multilayer Circuit Board

The circuit board includes many types of working layers, such as signal layers, protective layers, silkscreen layers, internal layers, etc. The roles of various layers are briefly introduced as follows:

(1) Protective Layer: Mainly used to ensure that areas on the circuit board that do not require tin plating are not plated, thus ensuring the reliability of the circuit board operation. Top Paste and Bottom Paste refer to the top and bottom solder resist layers, respectively; Top Solder and Bottom Solder refer to the solder paste protective layer and bottom solder paste protective layer, respectively.

(2) Signal Layer: Mainly used for placing components or wiring. Protel DXP typically includes 30 intermediate layers, namely Mid Layer1~Mid Layer30, which are used for placing signal lines, while the top and bottom layers are used for placing components or copper plating.

(3) Silkscreen Layer: Mainly used to print component serial numbers, production numbers, company names, etc., on the circuit board.

(4) Internal Layer: Mainly used as a signal wiring layer, with a total of 16 internal layers included in Protel DXP.

(5) Other Layers: Mainly include four types of layers.

Drill Guide Layer: Mainly used for marking the position of drilled holes on the printed circuit board.

Keep-Out Layer: Mainly used to draw the electrical border of the circuit board.

Drill Drawing Layer: Mainly used to set the shape of drilled holes.

Multi-Layer: Mainly used to set multiple layers.

Figure 4: Working Layers of Circuit Boards

This article introduces the concept, working principle, components, classification, and working layers of circuit boards. The price of circuit boards varies depending on the design, materials, number of layers, size, production quantity, manufacturing process, minimum line width and spacing, minimum hole diameter, number of holes, and special process requirements.