In integrated circuit application design, after completing the project schematic design, PCB layout design is necessary. PCB design is a crucial step. The quality of the design results directly affects the overall functionality of the design. Therefore, a reasonable and efficient PCB layout is essential for the successful debugging of chip circuit design. In this article, we will briefly discuss the key points in PCB layout design.

Key Points in PCB Layout Design

+

Component Package Selection

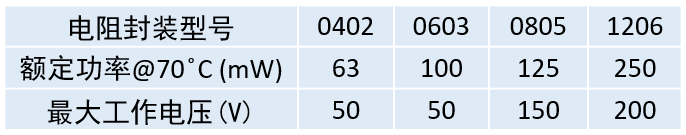

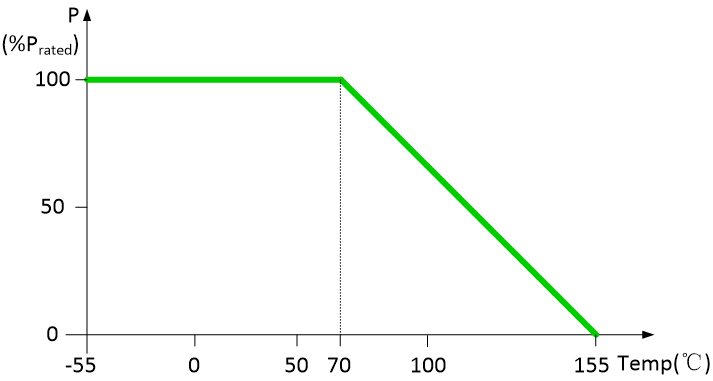

Resistor Selection: The selected resistor’s voltage rating, maximum power consumption, and temperature must not exceed the usage limits.

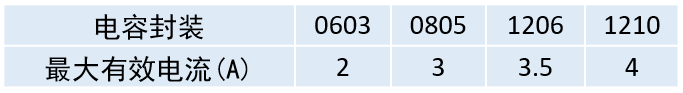

Capacitor Selection: The voltage rating and maximum effective current of the selected capacitor must also be considered.

Inductor Selection: The effective current and peak current of the selected inductor must be greater than the actual current flowing through the circuit.

+

Common Circuit Design Interference

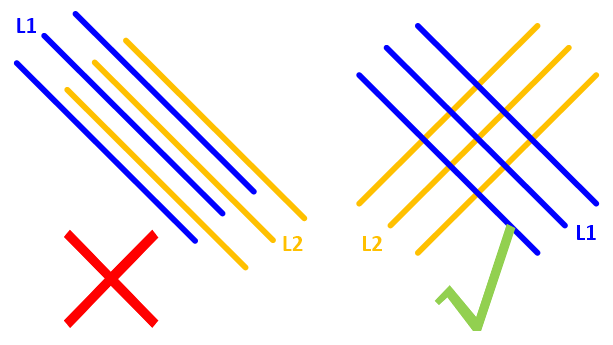

Crosstalk: When the distance of parallel wiring is too long, the mutual capacitance and mutual inductance between the wires can couple energy to adjacent transmission lines. Crosstalk can be reduced through the following methods:

1. Add safety traces

2. Whenever possible, make adjacent traces perpendicular to each other

3. Increase the spacing between parallel lines as they run

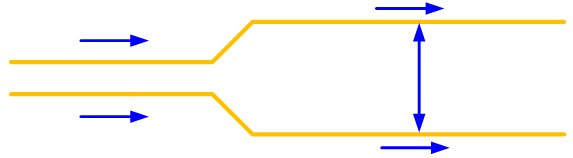

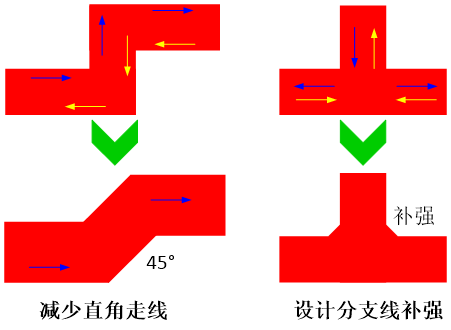

Reflection: Due to too many bends and branches in the wiring, impedance mismatch occurs on the transmission line. This can be improved by reducing the bends and branch lines on the line or avoiding right-angle wiring and branch line reinforcements.

+

Determine Grounding Method

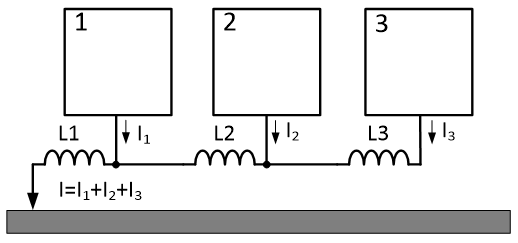

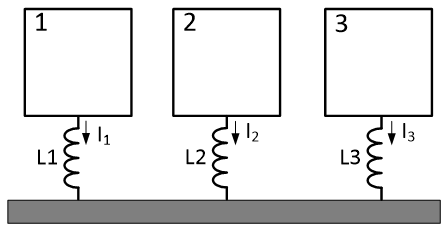

Single-point grounding (suitable for low-frequency circuits): All circuit ground wires connect to a common ground point, making wiring simple and reducing interference from ground loops.

Multi-point grounding (suitable for multi-layer circuit/high-frequency circuits): Each part of the system is grounded nearby, providing lower ground impedance.

+

Increase Filtering and Bypass Capacitors

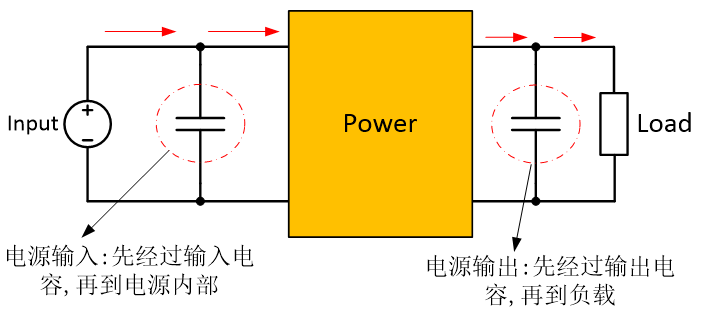

To ensure stable input/output voltage, add input/output capacitors.

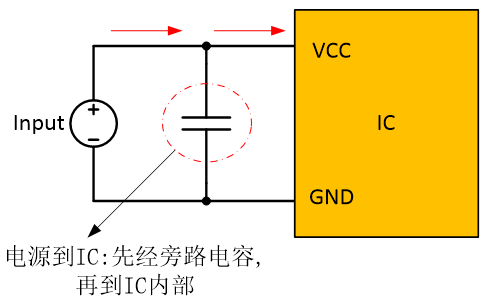

Add bypass capacitors between the power supply and IC to ensure stable input voltage and filter out high-frequency noise.

+

Impedance Position Design

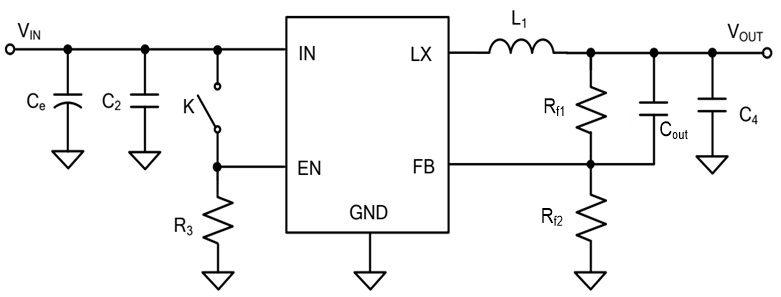

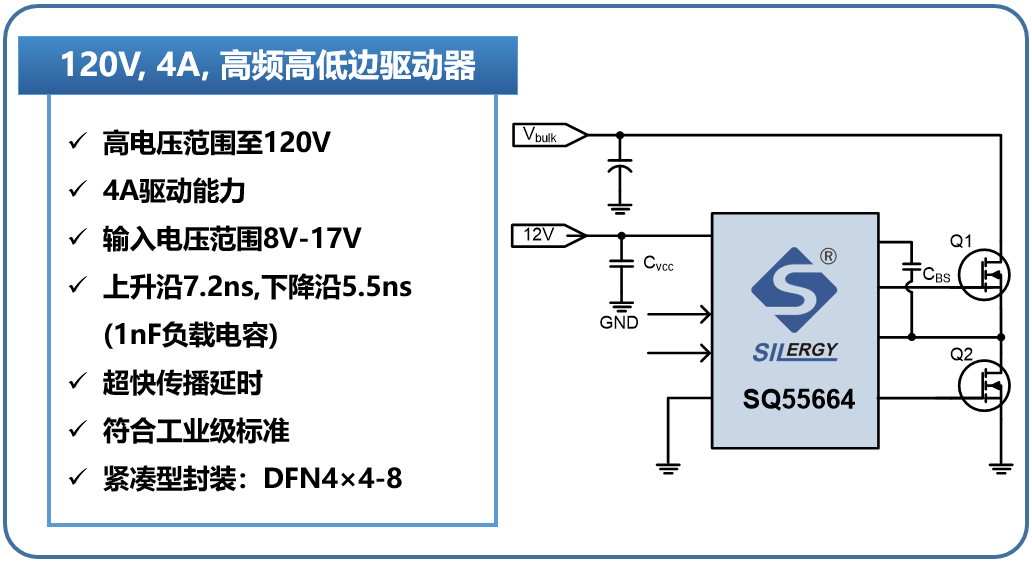

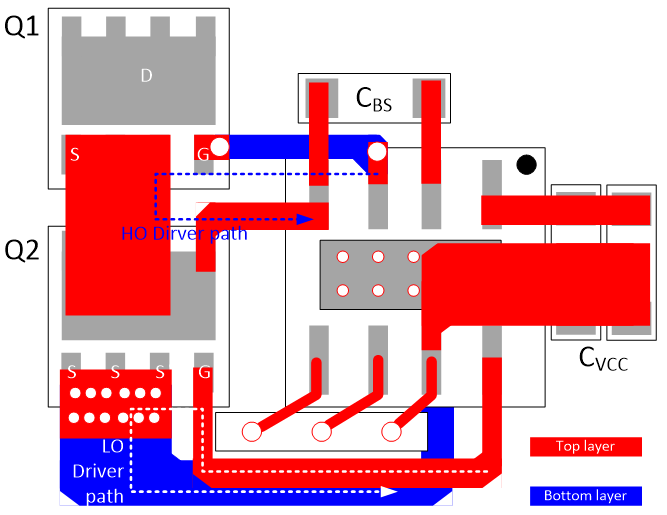

Generally, the higher the impedance position, the more susceptible it is to interference. Below is the PCB impedance position design of a synchronous buck chip.

PCB Layout Design Techniques

+

Power/Ground Line Processing

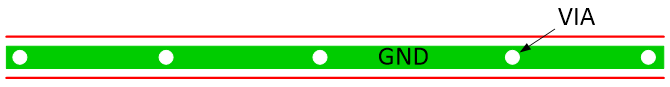

Even if the wiring throughout the PCB is well done, interference caused by inadequate consideration of power and ground lines can degrade product performance. When wiring, try to widen the power and ground lines, and it is best for the ground line to be wider than the power line. Their relationship is: Ground Line > Power Line > Signal Line.

For digital circuit PCBs, a wide ground wire can form a loop, constituting a ground network (this method cannot be used for analog circuits). Use large copper areas for ground lines, connecting all unused areas on the printed circuit board to ground. Alternatively, make a multi-layer board, with power and ground lines occupying one layer each.

+

Common Ground Handling for Digital and Analog Circuits

Common ground handling for digital and analog circuits: When digital and analog circuits coexist, wiring needs to consider the interference issues between them, especially noise interference on the ground line.

Digital circuits have high frequency, while analog circuits are sensitive; for signal lines, high-frequency signal lines should be kept as far away as possible from sensitive analog circuit components.

For ground lines, the entire PCB has only one external connection port, so it is necessary to handle the common ground issue internally. In the board, the digital ground and analog ground are actually separated and not connected, except at the port connecting the PCB to the outside (such as plugs), where there is a slight short circuit between the digital ground and analog ground. Please note that there is only one connection point.

+

Signal Line Distribution Layer

Signal lines on the power (ground) layer: When wiring in multi-layer printed boards, if there are not many remaining lines on the signal layer, adding more layers will cause waste and increase production workload and costs.

To resolve this contradiction, consider wiring on the power (ground) layer. First, use the power layer, and then the ground layer, as it is best to maintain the integrity of the ground layer.

+

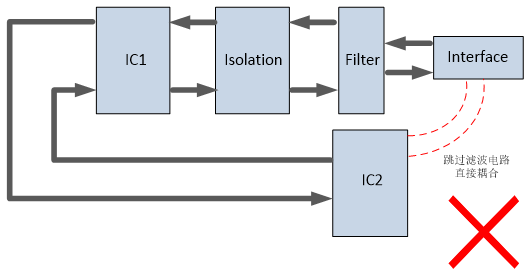

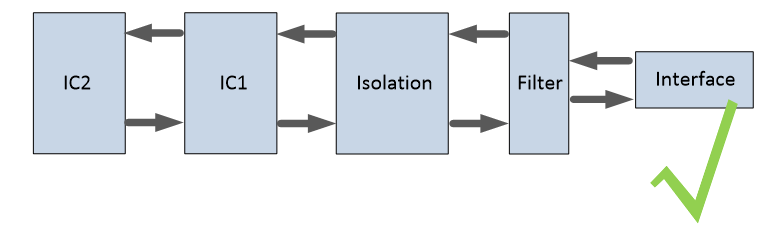

Signal Flow Direction Design

In PCB layout design, the principle of placing components in a straight line along the signal flow direction should be fully adhered to, avoiding back-and-forth routing as much as possible.

PCB Layout Design Examples

+

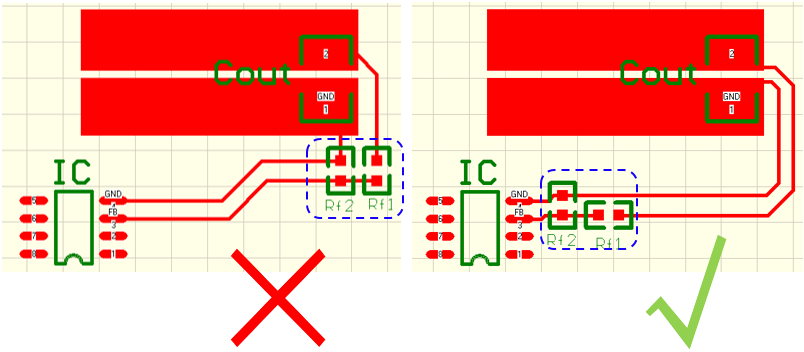

Layout Design Suggestions

1. Place the driver chip and power MOSFET as close as possible;

2. Place the VCC-GND (CVCC) / VB-VS (CBS) capacitors as close as possible to the chip;

3. Add a certain number of vias to the chip’s heat dissipation pad and connect them to GND (to increase heat dissipation and reduce parasitic inductance);

4. Route GND directly to the source of the MOSFET, avoiding overlap with the high-current path between the source and drain; apply the same GND routing principle for VS (avoid overlapping power and drive circuits);

5. Keep HO/LO routing as wide as possible (60mil-100mil, since the driving current is relatively high, to reduce the impact of parasitic inductance);

6. Keep the LIN/HIN logic input ports as far away from HS routing as possible (to avoid high voltage swings interfering with input signals).

Copyright Statement: This article is copyrighted by the original author and does not represent the views of the association. Articles promoted by the “Jiangxi Province Electronic Circuit Industry Association” are for sharing purposes only and do not represent the stance of this account. If there are copyright issues, please contact us for deletion.