(Source: MIT News)

Diffusion models (such as OpenAI’s DALL-E) are increasingly becoming effective assistants in design conception. Humans only need to input commands, and these systems can generate images, create videos, or optimize design drawings, leading to unexpected innovative solutions.

But did you know that generative artificial intelligence (GenAI) has also made breakthrough progress in the field of robotic manufacturing? The latest technology based on diffusion models can construct robot structures and their control systems from scratch. Regardless of whether user commands are received, these models can autonomously generate new designs and, after evaluation in a simulation environment, proceed to manufacturing.

Recently, the Computer Science and Artificial Intelligence Laboratory (CSAIL) at the Massachusetts Institute of Technology released results from two new robotic projects that utilize artificial intelligence to improve and accelerate robot design. The results were presented at the 2025 International Conference on Robotics and Automation.

Users only need to provide a draft of the robot’s 3D model and specify the dimensions of the parts that need improvement, and GenAI will automatically generate the optimal forms for these areas and conduct simulation testing. Once the system determines the best design, it can directly save the file and manufacture a fully functional robot using a 3D printer in one go, without the need for post-processing adjustments.

According to the team, this research can significantly reduce the typical trial-and-error process that engineers face in robot development, allowing designs to enter the prototyping phase more quickly.

Follow Replay Share Like Watch moreMIT Technology Review APP

0/0

00:00/02:20Progress bar, 0 percentPlay00:00/02:2002:20Fullscreen Playing at speed 0.5x 0.75x 1.0x 1.5x 2.0x Ultra HD Smooth

Continue watching

Robotic Design Enters the AI Era: Automatic Generation from Input Commands and Direct 3D Printing

Reprinted, Robotic Design Enters the AI Era: Automatic Generation from Input Commands and Direct 3D PrintingMIT Technology Review APPAdded to Top StoriesEnter comment Video Details

Optimizing Robot Jumping and Foot Design

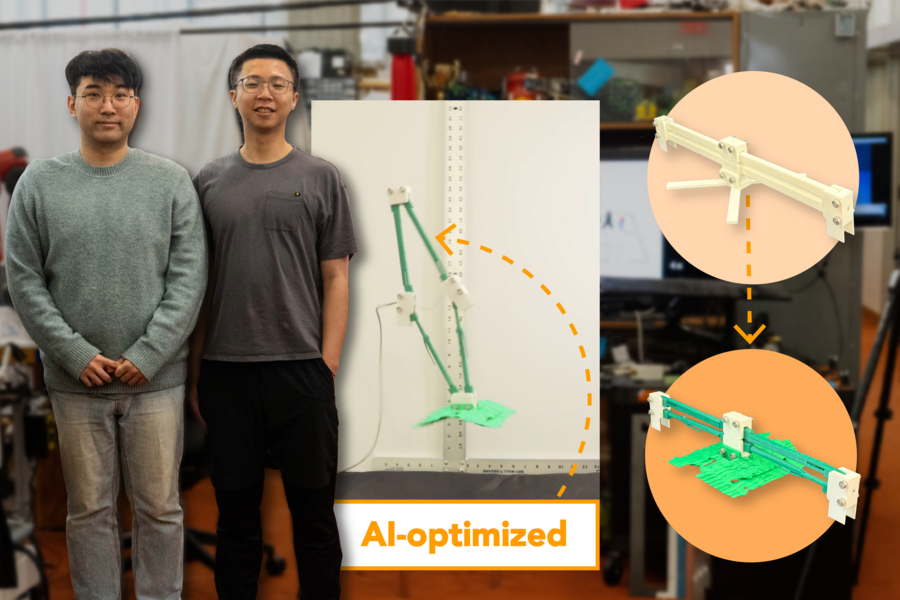

This technology’s most striking application case is the development of a micro-jumping robot. Researchers at MIT compared two versions: a prototype entirely designed by humans and an improved version optimized by the diffusion model. Although both used the same plastic material (PLA) and basic structure, the AI-optimized version achieved a 41% increase in jumping height—reaching about 2 feet (approximately 61 centimeters).

The secret to the performance improvement lies in the AI’s suggestion to change the originally straight block joint structure to a curved design. This subtle shape adjustment allows the robot to store and release energy more efficiently while maintaining structural strength.

During the development process, the AI started with the initial design and generated 500 shape variants through 5 iterations, ultimately determining an oddly shaped but significantly more efficient jumping solution. This design was scaled proportionally and 3D printed into a physical model for testing. Physical tests confirmed that this unique structure indeed significantly enhanced the robot’s jumping performance.

Byungchul Kim, a co-lead of the project and a postdoctoral researcher at CSAIL, pointed out that the advantage of diffusion models lies in their ability to discover unconventional optimization solutions: “We initially planned to reduce the weight by thinning the connecting parts to increase jumping height. However, the mechanical properties of traditional 3D printing materials can lead to fragile structures when overly thin. The diffusion model proposed an innovative solution—by designing special shapes to allow the robot to store more energy before takeoff while avoiding overly thin connections. This creative solution has given us new insights into the physical principles of robots.”

Jumping is just a basic capability; safe landing is equally critical. The research team again employed generative AI to design the robot’s feet, selecting the optimal solution after multiple rounds of simulation testing. The results showed that the improved robot’s probability of falling was reduced by 84% compared to the standard version. This dual enhancement in vertical jumping and stability confirms that generative AI can simultaneously optimize robot performance and reliability.

This breakthrough is not only applicable to jumping robots but holds significant value for all robotic systems requiring agility and precision. For example, manufacturing or household robot companies can adopt similar technologies to optimize prototype designs, significantly saving the time costs traditionally required for iterative modifications by engineers.

The Art of Balance Behind Jumping

To achieve the dual goals of high jumping and stable landing for the robot, the research team innovatively established a delicate balance between the two performance metrics. They quantified the jumping height and landing success rate as numerical parameters and used system training to find the optimal balance point between the two embedded vectors, thereby constructing the optimal three-dimensional structure.

Researchers noted that while the current AI-designed robots have surpassed human versions, there is still significant room for performance improvement. This iteration was limited by the properties of 3D printing materials; if lighter materials are used, future versions will achieve even higher jumping heights.

Johnson Wang, a co-lead of the project and a PhD student at MIT CSAIL, stated: “This research is the starting point for generative AI-assisted robot design. We plan to expand to more flexible design goals, such as directly using natural language commands to have the diffusion model generate robots that can grasp coffee cups or operate drills.”

Kim added that diffusion models can also optimize joint designs and innovate connection methods, potentially further enhancing jumping performance. The team is exploring increasing the number of motors to control jumping direction, thereby enhancing landing stability.

In the development of underwater gliding robots, the research team collaborated with the University of Wisconsin-Madison, testing various hydrodynamic shapes and ultimately developing robots for environmental monitoring and data collection.

The team input over 20 types of “ocean exploration shapes” into the AI model—including shapes of submarines, whales, manta rays, and sharks. The system ultimately generated two glider design proposals: a biplane style (similar to an airplane shape) and a quad-wing style (mimicking the fluid structure of a four-finned flatfish). This method created unconventional but more efficient gliding models.

Currently using standard 3D printing plastic materials, researchers believe that using lighter and stronger materials in the future could further enhance performance. By integrating generative AI with simulation technology, robots are not only becoming smarter but also making the entire construction process faster, more intuitive, and more efficient. From factory floors to future homes, this breakthrough may become a significant turning point in robot design and manufacturing.

Original link:

https://news.mit.edu/2025/using-generative-ai-help-robots-jump-higher-land-safely-0627