3D printing can manufacture parts with complex geometries and advanced materials. In the metal sector, advancements in this technology have opened new possibilities for many industries, including critical sectors requiring high precision and complex materials.Existing metal additive manufacturing technologies primarily process metal materials by melting or sintering, a process that is costly and limited by the physical and chemical properties of the materials. According to 3D printing technology references, a company named 3D Architech is developinggel-based metal 3D printing technology. DLP Technology for Printing Organic GelsThis technology first usesDigital Light Processing (DLP) technology (which projects a two-dimensional image of ultraviolet light onto a photosensitive resin tank for layer-by-layer curing) to print structured polymer gels based on N,N-Dimethylformamide (DMF)/Polyethylene Glycol Diacrylate (PEGda).After printing, DMF is replaced with water through solvent exchange, transforming the organic gel into a hydrogel. Subsequently,the hydrogel structure is immersed in a solution filled with metal ions, allowing the metal ions to swell the hydrogel scaffold. After that,calcination in air converts the swollen hydrogel containing metal salts into metal oxides, which are then reduced in a protective reducing gas (95% N₂, 5% H₂) to obtain dense components,realizing the shaping of metal products.Throughout the process, the component shape defined by DLP printing is preserved,and the conversion of metal salts in the polymer scaffold to metal oxides, followed by reduction to metals and alloys, only requires the target material to have a water-soluble precursor, and the intermediate oxides formed after calcination can be reduced by hydrogen.

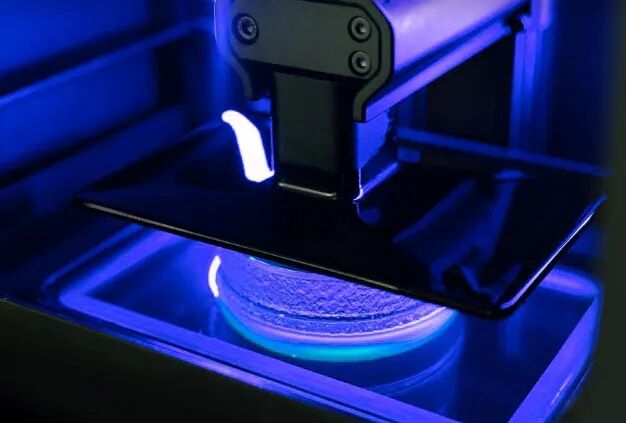

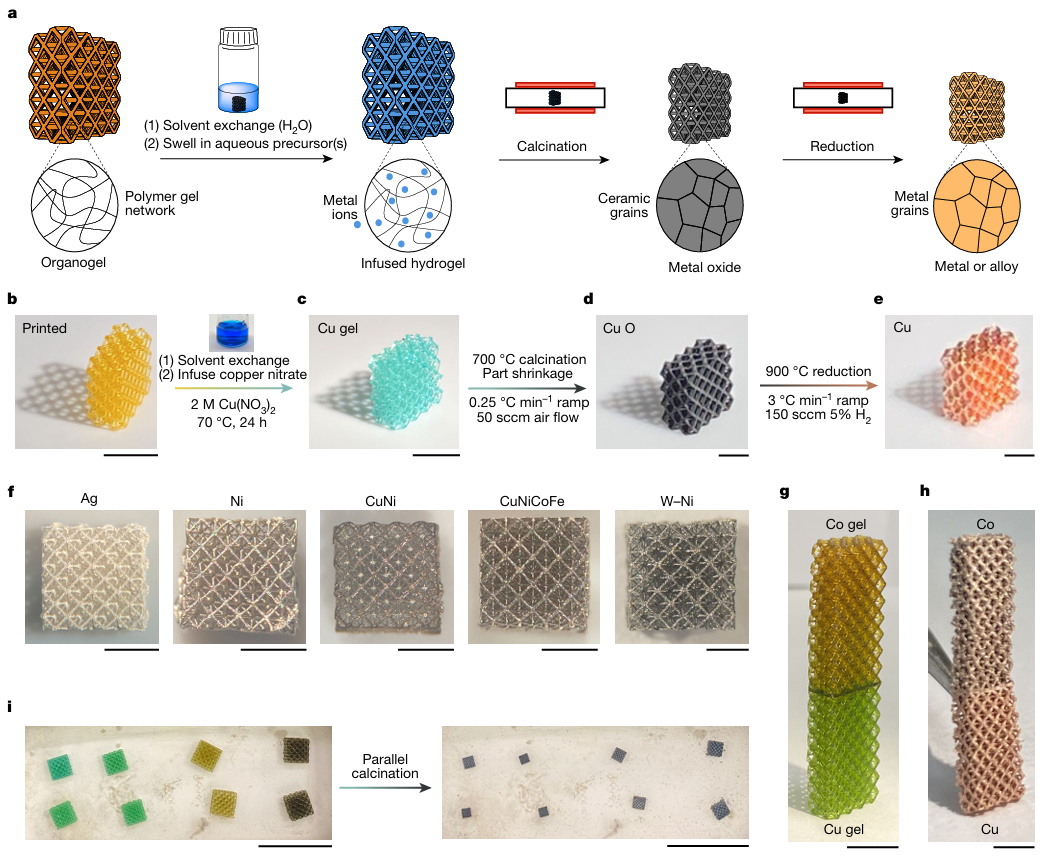

DLP Technology for Printing Organic GelsThis technology first usesDigital Light Processing (DLP) technology (which projects a two-dimensional image of ultraviolet light onto a photosensitive resin tank for layer-by-layer curing) to print structured polymer gels based on N,N-Dimethylformamide (DMF)/Polyethylene Glycol Diacrylate (PEGda).After printing, DMF is replaced with water through solvent exchange, transforming the organic gel into a hydrogel. Subsequently,the hydrogel structure is immersed in a solution filled with metal ions, allowing the metal ions to swell the hydrogel scaffold. After that,calcination in air converts the swollen hydrogel containing metal salts into metal oxides, which are then reduced in a protective reducing gas (95% N₂, 5% H₂) to obtain dense components,realizing the shaping of metal products.Throughout the process, the component shape defined by DLP printing is preserved,and the conversion of metal salts in the polymer scaffold to metal oxides, followed by reduction to metals and alloys, only requires the target material to have a water-soluble precursor, and the intermediate oxides formed after calcination can be reduced by hydrogen.

Technical Principles and Printable Materials

This technology demonstrates diversity inprintable materials, allowing for the preparation ofcopper, nickel, silver, and their alloys, as well as more complex materials such as high-entropy alloys CuNiCoFe and refractory alloys W-Ni, and composites. This diversity enables the customization of properties such as strength, flexibility, and conductivity.

Additionally, this technology has the advantage ofsimultaneously printing multiple organic gels, which can be swollen in different solutions and then co-calcined/reduced, making the transition from the R&D phase tomass production of customizedand optimized components possible. Combined with the vast material diversity, it canadapt to the needs of different industry clients.

Batch Printing of Parts

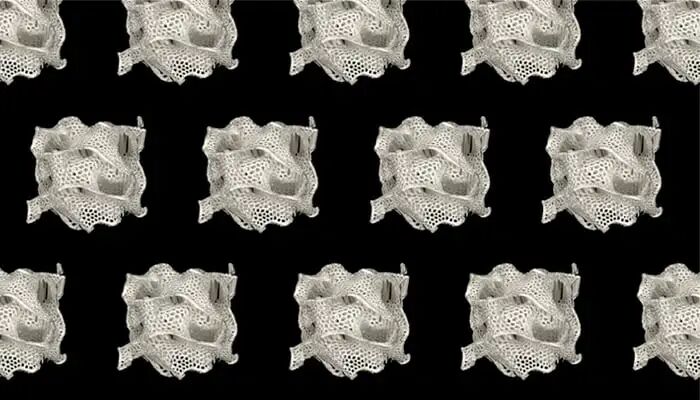

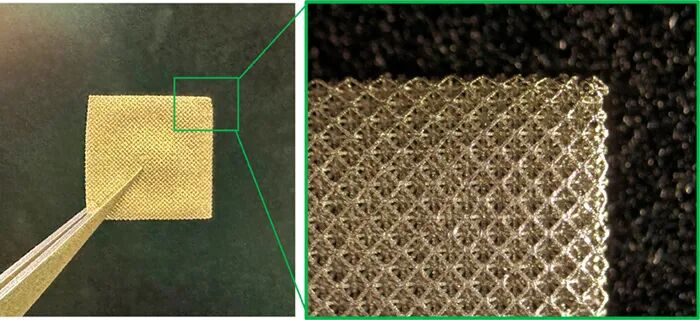

Currently, the company has been able to achieve10um level featuresthrough advanced microstructure design and printing, using cost-effective materials to reduce overall costs in the production process and enhance printing efficiency.They are currently focusing on fields such as cooling, energy, and manufacturing. They are working on producing heat sinks to significantly improve cooling efficiency and performance in data centers, as well as electrolyzer components for green production. Furthermore, they are exploring applications such as porous metal structures for fuel cells and other innovative solutions.

Ultra-Fine Structure Printing3D Architech’s gel metal 3D printing technology has transformed traditional hot processing forms with“cold forming.” In application, the company has alreadyproduced heat sinks with micron-level features using pure copper and copper alloys, significantly reducing thermal resistance and pressure drop, achieving excellent heat dissipation. In addition to heat sinks, the company plans to develop core materials for heat spreaders and two-phase cooling systems.This technology has also been applied in fuel cells and water electrolysis.3D Architechhas developed porous metalgas diffusion layers and porous transport layers with micron-level precision, ensuring uniform gas flow and rapid discharge, significantly enhancing the efficiency and performance of clean energy technologies. Therefore, it can be seen that this technology has application advantages in the development of electrodes for batteries, catalysts, and other energy conversion applications.Note:This articlewas created by 3D printing technology references and is not authorized for reproduction without contact..Reposting is welcome

Ultra-Fine Structure Printing3D Architech’s gel metal 3D printing technology has transformed traditional hot processing forms with“cold forming.” In application, the company has alreadyproduced heat sinks with micron-level features using pure copper and copper alloys, significantly reducing thermal resistance and pressure drop, achieving excellent heat dissipation. In addition to heat sinks, the company plans to develop core materials for heat spreaders and two-phase cooling systems.This technology has also been applied in fuel cells and water electrolysis.3D Architechhas developed porous metalgas diffusion layers and porous transport layers with micron-level precision, ensuring uniform gas flow and rapid discharge, significantly enhancing the efficiency and performance of clean energy technologies. Therefore, it can be seen that this technology has application advantages in the development of electrodes for batteries, catalysts, and other energy conversion applications.Note:This articlewas created by 3D printing technology references and is not authorized for reproduction without contact..Reposting is welcome

Welcome to join the PhD and Master exchange groupQ group:248112776

Further Reading:

1. Researchers Develop a New Type of High-Performance Metal Alloy for Space Use

2. Latest Technological Advances in Copper and Copper Alloy 3D Printing 2025: Based on Laser/Electron Beam Melting and Energy Deposition

3. American Users Transform Business Using Huazhu High-Tech Metal 3D Printing Equipment

4. New Progress in the International Market Expansion of Zhongti New Materials Metal 3D Printing Powder