Source: Concrete Decoration

Exploring a Series of Bicycle Bridge Structures with 3D Printed Concrete in the Netherlands

From innovative technology to the exploration of building diverse bridge structures

From innovative technology to the exploration of building diverse bridge structures

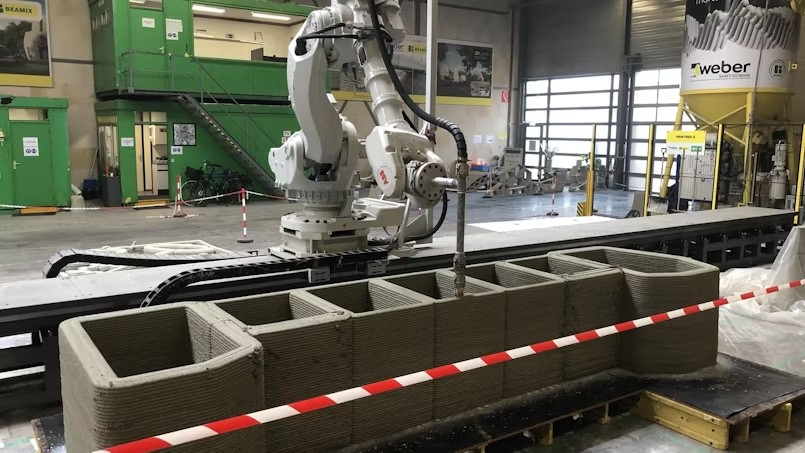

In 2017, the world’s first 3D printed concrete bicycle bridge was completed in the Gemert region of Brabant, Netherlands. The ongoing exploration and reflection on whether 3D printing concrete technology can print supporting structures of any form is a key aspect of this project. Since 2017, the Netherlands has continuously utilized 3D printed concrete technology to complete numerous projects, with the most notable being the longest (29 meters) 3D printed concrete bridge completed in Nijmegen in 2021. The Dutch team has never ceased its exploration and research into 3D printed concrete technology, and this year, North Holland has constructed a series of 3D printed concrete bridges, further advancing the development in this field.When thinking of bridges and concrete, one might envision massive solid bridge piers and road surfaces, rather than small landscape bridges with hollow structures and a thickness of only 5 centimeters.This is the thickness of the thinnest part of the new 3D printed concrete bicycle bridge on the N243 highway in North Holland. This bridge is 14.8 meters long, making it the longest single-span bridge built using this method.” said the project manager of Weber Beamix: “This is a milestone for 3D printed concrete load-bearing structures.”

Image©Witteveen+Bos, the North Holland bridge has completed partial connections near the final project site, and load tests have been conducted.

During on-site testing, the project team placed water tanks on the bridge, testing a load of 1000 kg/m², and the significant test results led the project team to decide to put the four bridges into use by the end of 2023.

#Driven by Innovation and Sustainability

The series of bridges spans 9 to 12 meters, with each bridge having a unique shape, marking a significant step in the development phase of constructive 3D printed concrete. This development began in 2015 when Professor Theo Salet from Eindhoven University of Technology, along with concrete manufacturers Weber Beamix, engineering company Witteveen+Bos, construction company BAM, and other companies and investors, started researching 3D printed concrete. Image ©Tektoniek, the first 3D printed concrete bicycle bridge located in Gemert, NetherlandsAt that time, BAM was implementing a Gemert ring road project, which also required a bicycle bridge, so they proposed the use of 3D printed concrete technology. The construction team has since mastered the 3D printing concrete process in the university laboratory and is focused on researching whether this technology can create richer architectural elements.Innovation is a driving force and also represents the potential of 3D printed concrete technology in mass customization, such as bridges, where each project has different requirements: longer spans, wider road surfaces, or specific objects needed in certain locations. Additionally, materials can be placed where needed without being constrained by molds, saving a significant amount of mold material.

Image ©Tektoniek, the first 3D printed concrete bicycle bridge located in Gemert, NetherlandsAt that time, BAM was implementing a Gemert ring road project, which also required a bicycle bridge, so they proposed the use of 3D printed concrete technology. The construction team has since mastered the 3D printing concrete process in the university laboratory and is focused on researching whether this technology can create richer architectural elements.Innovation is a driving force and also represents the potential of 3D printed concrete technology in mass customization, such as bridges, where each project has different requirements: longer spans, wider road surfaces, or specific objects needed in certain locations. Additionally, materials can be placed where needed without being constrained by molds, saving a significant amount of mold material.

Image©Witteveen+Bos

Image©Witteveen+Bos

#Thinking About Technology Innovation from the Material Itself

What can we learn from these pioneering projects? This technology can achieve many things, and the key is to start thinking from the printer, materials, and the possibilities that this technology offers. For example, concrete has excellent compressive strength, so the design process must fully utilize the material’s high compressive strength; otherwise, it will be challenging to explore the design applications of the material in terms of shaping.

Image©Witteveen+Bos

Bridge Gemert on the pressure bench at Eindhoven University of Technology

Witteveen + Bos designed and calculated the bridge located in Gemert, which had to be completed in a very short time; the idea was proposed in spring, and the bridge had to be finished by September. During multiple design workshops, the project team determined the design and structural principles of the bridge: many concrete printing elements are stacked together through prestressing. To make it easier for everyone to understand, an expert from the project team took a stack of books from a shelf for comparison, pressing them together in the air. By applying horizontal pressure in advance, this stack of books remains stable as a whole.

Image©Witteveen+Bos

Subsequently, the project team discussed the possibilities and impossibilities of 3D printing. For example, printing cannot be done at sharp angles, and printing cannot be stopped during the process. Additionally, the maximum load of the bridge crane in their university laboratory is also very limited. Therefore, the bridge was printed in six parts instead of theoretically printing it all at once.

Image©Witteveen+Bos

Image©Witteveen+Bos

#Reinforcement Placement

Through this conceptual design, Witteveen+Bos first performed calculations in digital parameter software, then used finite element methods to calculate the strength of complex architectural elements. Engineers conducted material tests in collaboration with university researchers. Bruels explained that the concrete used consists of mortar mixed with steel wires, similar to laminated glass, where the steel wires ensure that the glass does not shatter further when it breaks (similar to tempered glass).The university laboratory printed and assembled a 1:2 scale model of this concrete, then conducted loading pressure tests, allowing researchers to record experimental parameters and analyze the force distribution of the bridge. Finally, these elements were printed at a 1:1 scale and transported to the construction site for assembly, prestressing, hoisting into place, and loading with water tanks. In October 2017, the world’s first 3D printed reinforced concrete bridge was opened.

Image©Witteveen+Bos

The Nijmegen 3D printed concrete bicycle bridge has multiple support points

Image ©BAM

The Nijmegen 3D printed concrete bicycle bridge is composed of small cross-section

components connected together, bearing tension

Image©Witteveen+Bos

Image©Witteveen+Bos

#”Family-style” Bridge System

At the end of 2018, North Holland province made a request to manufacture four bicycle bridges as part of the N243 highway reconstruction. For sustainability reasons, the province chose 3D printed concrete technology and saw opportunities in the parametric design process, they did not draw four independent structural drawings but designed a “family” of bridges with smoother and more curved shapes.In Eindhoven’s laboratory, components were first printed, and the calculated shear forces were tested, which played a normative and decisive role in the overall slender form. These components were printed at Weber’s factory in Eindhoven and then transported to North Holland. When some components were found to have capillary cracks, the situation became tense, as this was a design that had undergone considerable optimization—more critical than the Nijmegen bridge. The project team immediately checked all aspects of the project.

Image©Witteveen+Bos

North Holland 3D concrete printed bridges, their

curved sections are inclined along the length of the bridge

After testing in the university laboratory, the project team concluded that there were no issues, the cracks were located at the layering points, which is a common phenomenon within the acceptable range of 3D printed concrete, and after applying prestressing at the jointing stage, these cracks would not affect the strength and toughness of the bridge. By the end of 2022, the first bridge was assembled after successfully completing a test load of 30,000 kilograms with water tanks. Due to the larger size of the third bridge (14.8 meters), testing was similarly conducted on-site in August 2023.

#Future

When asked about the further development of 3D printed concrete structures, Witteveen+Bos mentioned a bridge developed for a construction exhibition in Germany.

Image©Witteveen+Bos North Holland bridge produced in the 3D printing factory

The project personnel introduced: “We did not print the entire cross-section of the bridge in one unit, but made two 3D printed concrete side tubes, with the bridge deck located in the middle. This is an interesting step because it allows you to print large components using less material, and the two side tubes, due to their 3D printing specificity, become two independent load-bearing structures, forming the main load-bearing body of the bridge. I see more possibilities for 3D printed concrete in this combination of construction systems.”

Video Recommendations

Book Recommendations

What Everyone is Reading

Click the lower left corner “Read the original text”, to purchase the annual publication~

Due to WeChat changing its push rules, articles no longer display in chronological order. If you do not click“Looking”or have not“Starred”, you may not see our push notifications! If you do not want to miss the exciting news from “Prefabricated Building Network” every day at noon, please remember to set us as“Starred”.

Due to WeChat changing its push rules, articles no longer display in chronological order. If you do not click“Looking”or have not“Starred”, you may not see our push notifications! If you do not want to miss the exciting news from “Prefabricated Building Network” every day at noon, please remember to set us as“Starred”.

Thank you again for your attention!