AM Yidao Introduction:Since the inception of 3D printing technology, it has been plagued by a stubborn problem—support structures.These annoying supports not only waste materials but also increase post-processing workload, and even affect print quality and mechanical strength.However, a groundbreaking study from the University of Manchester is completely changing this situation!The neural network slicing algorithm proposed in the paper “Neural Slicer for Multi-Axis 3D Printing” brings us a brand new multi-axis non-planar slicing method, opening the door to a support-free era of 3D printing.

AM Yidao Introduction:Since the inception of 3D printing technology, it has been plagued by a stubborn problem—support structures.These annoying supports not only waste materials but also increase post-processing workload, and even affect print quality and mechanical strength.However, a groundbreaking study from the University of Manchester is completely changing this situation!The neural network slicing algorithm proposed in the paper “Neural Slicer for Multi-Axis 3D Printing” brings us a brand new multi-axis non-planar slicing method, opening the door to a support-free era of 3D printing. This technology is not just another fancy concept in academia, but a mature algorithm that can be practically applied to complex geometries.It cleverly plans the printing path using neural network technology, allowing the print head to print along non-planar curved layers, thereby eliminating or significantly reducing the need for supports while greatly enhancing the mechanical performance of the printed parts.Relevant open-source links are at the end of this article!Pain Points and Constraints of Traditional Planar SlicingTraditional FDM printing technology constructs objects by stacking layers in a planar manner. Although this method is simple and intuitive, it has three significant drawbacks.

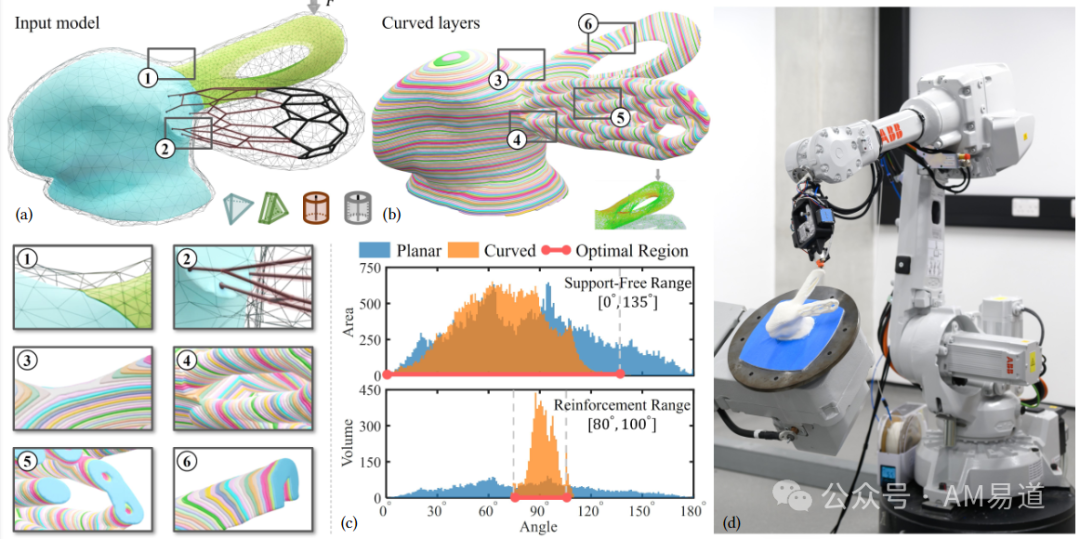

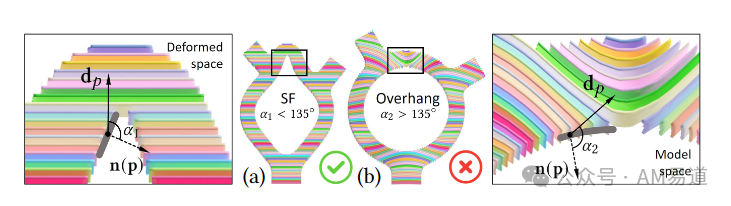

This technology is not just another fancy concept in academia, but a mature algorithm that can be practically applied to complex geometries.It cleverly plans the printing path using neural network technology, allowing the print head to print along non-planar curved layers, thereby eliminating or significantly reducing the need for supports while greatly enhancing the mechanical performance of the printed parts.Relevant open-source links are at the end of this article!Pain Points and Constraints of Traditional Planar SlicingTraditional FDM printing technology constructs objects by stacking layers in a planar manner. Although this method is simple and intuitive, it has three significant drawbacks. As shown in Figure 1, traditional planar slicing can only construct models in a single direction, leading to weak connections between layers, especially when the force direction is perpendicular to the layer lines, making the printed parts prone to inter-layer fractures.Another issue is the handling of overhang structures.When a model has overhangs exceeding a certain angle (usually 45°), support structures must be added; otherwise, the printing material will sag in mid-air, leading to print failure.These supports not only increase material consumption and printing time but also leave marks after removal, affecting surface quality.Finally, the inherent stair-step effect of planar slicing can lead to rough surfaces, impacting aesthetics and functionality.While reducing layer height can improve this, it significantly increases printing time, creating a dilemma.Neural Slicer: A Neural Network-Based Multi-Axis Non-Planar Slicing AlgorithmCore Idea of the AlgorithmThe core idea of Neural Slicer is to transform the non-planar slicing problem into an optimizable mathematical problem, constructing a mapping from the input model to the optimized slicing using a neural network (a computational model that mimics the structure of the human brain).Unlike previous methods, this approach can directly optimize the printing direction in the original model space rather than indirectly optimizing in a deformed space, thus avoiding mapping distortion issues.

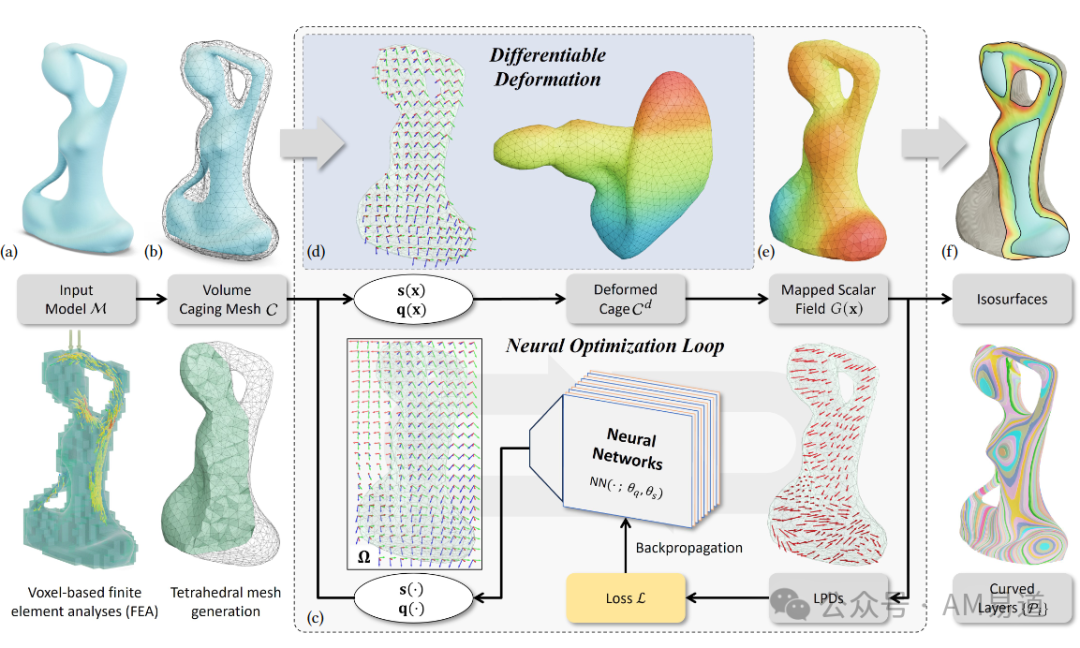

As shown in Figure 1, traditional planar slicing can only construct models in a single direction, leading to weak connections between layers, especially when the force direction is perpendicular to the layer lines, making the printed parts prone to inter-layer fractures.Another issue is the handling of overhang structures.When a model has overhangs exceeding a certain angle (usually 45°), support structures must be added; otherwise, the printing material will sag in mid-air, leading to print failure.These supports not only increase material consumption and printing time but also leave marks after removal, affecting surface quality.Finally, the inherent stair-step effect of planar slicing can lead to rough surfaces, impacting aesthetics and functionality.While reducing layer height can improve this, it significantly increases printing time, creating a dilemma.Neural Slicer: A Neural Network-Based Multi-Axis Non-Planar Slicing AlgorithmCore Idea of the AlgorithmThe core idea of Neural Slicer is to transform the non-planar slicing problem into an optimizable mathematical problem, constructing a mapping from the input model to the optimized slicing using a neural network (a computational model that mimics the structure of the human brain).Unlike previous methods, this approach can directly optimize the printing direction in the original model space rather than indirectly optimizing in a deformed space, thus avoiding mapping distortion issues. As shown in Figure 3, the entire algorithm process is divided into three main steps:

As shown in Figure 3, the entire algorithm process is divided into three main steps:

- Input Model Preprocessing

- Mapping Optimization

- Post-Processing to Generate Surface Layers

In the preprocessing stage, the algorithm first converts the input model into an implicit function H(x) (a mathematical equation describing the shape of the object, similar to a “distance function from points to the surface”), and calculates the internal stress field through finite element analysis (a computational method simulating the stress state of an object).Then, it constructs a “volume cage mesh C” as the computational domain, which will serve as the intermediate representation for optimization.Mapping optimization is the core part of the algorithm.The two continuous functions q(x) and s(x) shown in Figure 3(c) are the core components of the algorithm, acting like a navigation system guiding each point of the 3D model.The q(x) function acts like a compass, indicating the direction in which each point of the model should rotate. Here, quaternions are used to represent rotation, providing smoother transitions compared to the common angular representation (Euler angles), avoiding sudden jumps.The s(x) function acts like a scaling regulator, determining whether each point should be enlarged or reduced, and by how much. Together, these two functions perfectly control the deformation of the model.Traditional mathematical formulas struggle to describe complex 3D rotation and scaling patterns, but neural networks can gradually learn this complex relationship. “Differentiable” means the system can adjust and improve step by step.The entire optimization process is akin to scoring the quality of 3D printing and continuously improving to achieve the highest score. Various loss functions serve as different scoring criteria, such as “support-free score”, “mechanical strength score”, and “printing smoothness score”.The system weighs the importance of these scores to find an optimal balance, ultimately generating a scalar field G(x), which corresponds to the optimal printing height for each point.The post-processing stage converts these optimization results into actual printable surface layers. Imagine drawing contour lines on a map, connecting points of equal elevation.Similarly, the system extracts points with the same value from G(x) to form isosurfaces in 3D space.These isosurfaces intersect with the boundary of the original model H(x)≤0 to obtain the final surface printing layers, which ensure print quality while avoiding support structures.If AM Yidao were to summarize the core idea of the Neural Slicer algorithm in one sentence:The algorithm transforms the non-planar slicing problem into a neural network optimization problem, directly optimizing the printing direction in the original model space by learning continuous deformation mapping functions, generating surface layers that meet support-free requirements and enhance strength, thus achieving support-free manufacturing of complex geometries in multi-axis 3D printing.Loss Function DesignOne of the major innovations of Neural Slicer mentioned earlier is its carefully designed loss function system.The loss function acts as a scoring standard for print quality, with lower scores indicating better quality.

These include:

- Strength Enhancement Loss (LSR)ensures that the printing direction is perpendicular to the maximum principal stress direction, enhancing mechanical strength.

- Support-Free Loss (LSF)ensures that the angle between the printing direction and the surface normal does not exceed 135°.

- Point Overhang Avoidance Loss (LPO)prevents the generation of printing directions that lead to local minima.

- Collision Avoidance Loss (LCA)ensures that the print head does not collide with the working surface locally.

- Harmonic Smoothing Loss (LHS and LHQ)controls the smoothness of q(x) and s(x), ensuring continuous and smooth movement of the print head.

These loss functions work together to form a multi-objective optimization problem:

L = w₁LSF + w₂LSR + w₃LPO + LHS + LHQ

where w₁, w₂, and w₃ are the weight coefficients of each loss term.

Readers interested in learning more about algorithm optimization can refer to the original text.

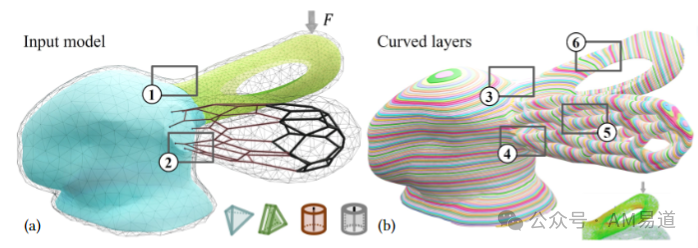

Astonishing Experimental ResultsThe performance of Neural Slicer has been validated on various complex models, including the Bunny Head model, Yoga model, and Shelf model.Figures 1 and 3 demonstrate the application of the algorithm on the Bunny Head and Yoga models, with the generated surface layers perfectly adapting to the model’s geometry, and without the need for support structures. Performance of Complex Topology ModelsFigure 6 showcases the outstanding performance of Neural Slicer on the highly complex Shelf model.

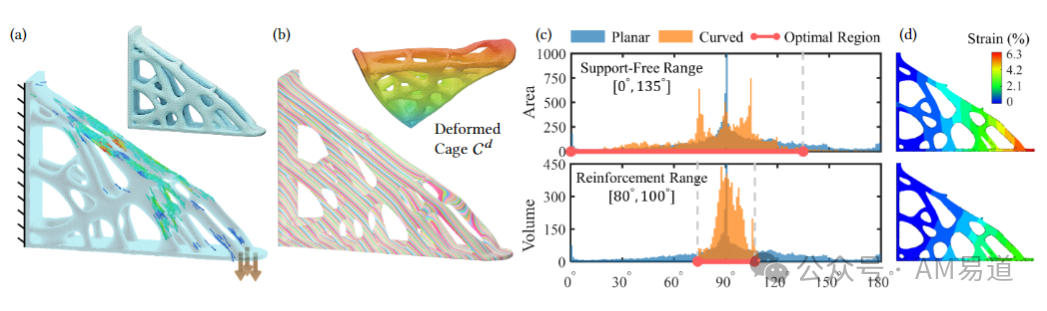

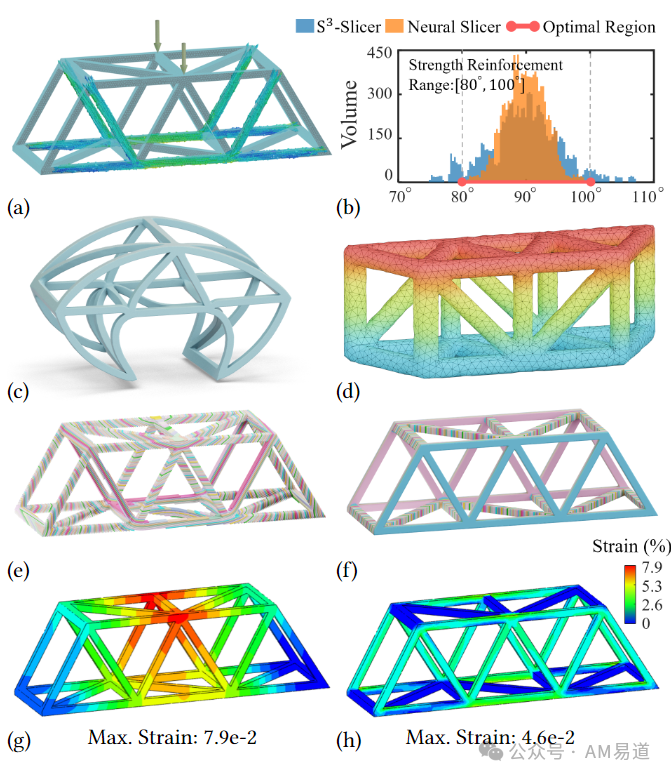

Performance of Complex Topology ModelsFigure 6 showcases the outstanding performance of Neural Slicer on the highly complex Shelf model. This model’s topological complexity far exceeds that of ordinary models.Figure 6(a) shows the stress field distribution under a given force (indicated by the arrows), obtained through finite element analysis.Figure 6(b) displays the surface layers generated by Neural Slicer, clearly showing that these layers perfectly conform to the model’s shape.Figure 6(c) quantifies the algorithm’s performance further; the upper graph shows that in terms of support-free (SF) requirements, most areas maintain angles within the [0°,135°] range;the lower graph indicates that in terms of strength enhancement (SR) requirements, most areas concentrate within the [80°,100°] range, indicating that the printing direction is nearly perpendicular to the maximum stress direction.Figure 6(d) presents finite element simulation results, demonstrating that the surface layers generated by Neural Slicer (lower image) significantly reduce strain distribution in the model under stress compared to planar layers (upper image).The Key Role of Point Overhang Avoidance LossFigure 11 illustrates the critical impact of Point Overhang Avoidance Loss (LPO) on print quality.

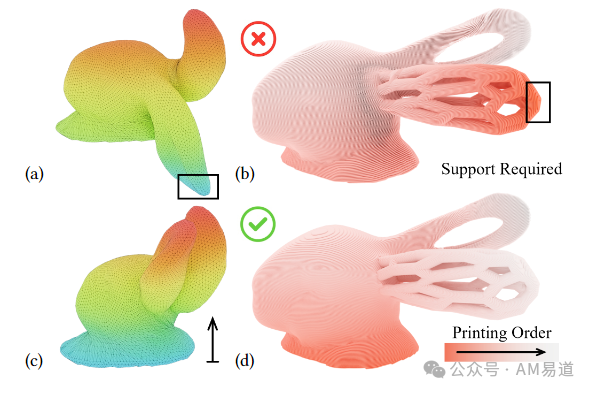

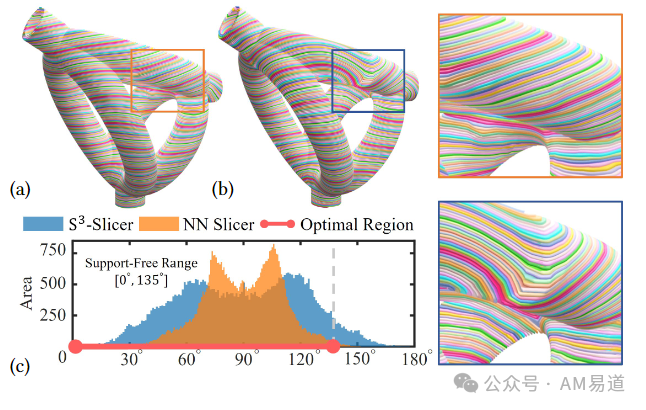

This model’s topological complexity far exceeds that of ordinary models.Figure 6(a) shows the stress field distribution under a given force (indicated by the arrows), obtained through finite element analysis.Figure 6(b) displays the surface layers generated by Neural Slicer, clearly showing that these layers perfectly conform to the model’s shape.Figure 6(c) quantifies the algorithm’s performance further; the upper graph shows that in terms of support-free (SF) requirements, most areas maintain angles within the [0°,135°] range;the lower graph indicates that in terms of strength enhancement (SR) requirements, most areas concentrate within the [80°,100°] range, indicating that the printing direction is nearly perpendicular to the maximum stress direction.Figure 6(d) presents finite element simulation results, demonstrating that the surface layers generated by Neural Slicer (lower image) significantly reduce strain distribution in the model under stress compared to planar layers (upper image).The Key Role of Point Overhang Avoidance LossFigure 11 illustrates the critical impact of Point Overhang Avoidance Loss (LPO) on print quality. This ablation study (testing the importance of a component by removing it) compares results with and without LPO enabled.As shown in Figures 11(a)(c), when LPO is disabled, the deformation cage Cd exhibits noticeable distorted areas (marked with ×), corresponding to model parts that form local minima, leading to overhang issues.In contrast, Figures 11(b)(d) show that with LPO enabled, the deformation cage is smoother, and the printing order (from pink to gray) is more reasonable, ensuring that material always accumulates on already printed sections rather than printing in “mid-air”.LPO allows the print head to move smoothly along the optimized path, significantly improving print success rates and quality. Especially for complex models like the Bunny Head, the application of LPO enables areas that would typically require substantial support, such as the ears, to be printed entirely without support.Significant Improvement in Mechanical PerformanceFigure 14 details the actual printing results of the Bridge model, comparing the outcomes of Neural Slicer and the S³ slicer.S³ slicer is another non-planar slicing method published by the team two years ago.

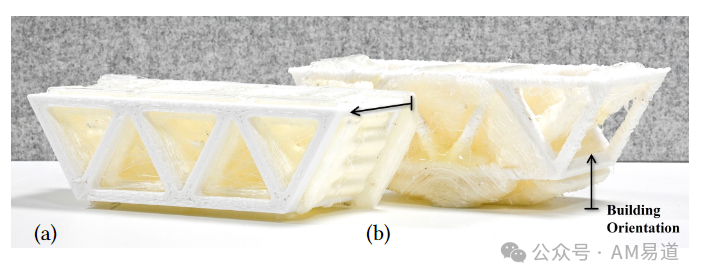

This ablation study (testing the importance of a component by removing it) compares results with and without LPO enabled.As shown in Figures 11(a)(c), when LPO is disabled, the deformation cage Cd exhibits noticeable distorted areas (marked with ×), corresponding to model parts that form local minima, leading to overhang issues.In contrast, Figures 11(b)(d) show that with LPO enabled, the deformation cage is smoother, and the printing order (from pink to gray) is more reasonable, ensuring that material always accumulates on already printed sections rather than printing in “mid-air”.LPO allows the print head to move smoothly along the optimized path, significantly improving print success rates and quality. Especially for complex models like the Bunny Head, the application of LPO enables areas that would typically require substantial support, such as the ears, to be printed entirely without support.Significant Improvement in Mechanical PerformanceFigure 14 details the actual printing results of the Bridge model, comparing the outcomes of Neural Slicer and the S³ slicer.S³ slicer is another non-planar slicing method published by the team two years ago. The layers generated by Neural Slicer are smoother, and the printing direction (indicated by arrows) is more reasonable, while the layers generated by the S³ slicer exhibit noticeable discontinuities and unreasonable printing directions.Most impressively, the mechanical performance of the printed parts has significantly improved.

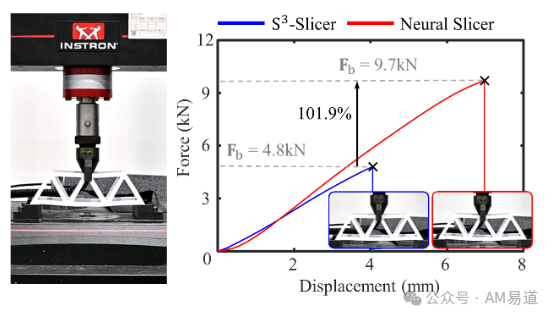

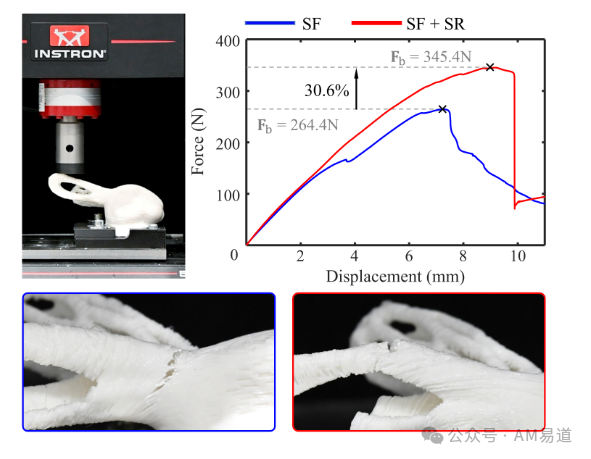

The layers generated by Neural Slicer are smoother, and the printing direction (indicated by arrows) is more reasonable, while the layers generated by the S³ slicer exhibit noticeable discontinuities and unreasonable printing directions.Most impressively, the mechanical performance of the printed parts has significantly improved. As shown in Figure 15, a three-point bending test on the Bridge model indicates that the surface layers generated by Neural Slicer improved the fracture force by 101.9%, from 4.8kN to 9.7kN.Figure 16 displays the compression test results for the Bunny Head model, showing that after incorporating strength enhancement (SR) requirements, the fracture force increased from 264.4N to 345.4N, a rise of 30.6%.

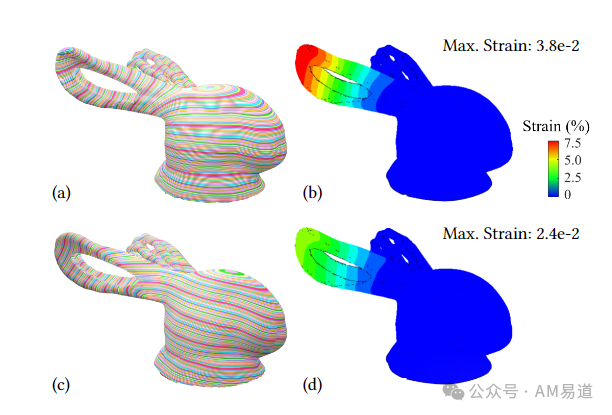

As shown in Figure 15, a three-point bending test on the Bridge model indicates that the surface layers generated by Neural Slicer improved the fracture force by 101.9%, from 4.8kN to 9.7kN.Figure 16 displays the compression test results for the Bunny Head model, showing that after incorporating strength enhancement (SR) requirements, the fracture force increased from 264.4N to 345.4N, a rise of 30.6%. More importantly, the fracture mode has also changed: from breaking at the ear root to breaking at the ear hole, which aligns with the predictions from finite element analysis.The finite element analysis (FEA) results in Figure 10 further confirm that compared to slicing that only considers support-free (SF) requirements, slicing that simultaneously considers both support-free (SF) and strength enhancement (SR) can reduce the maximum strain by 36.8%, which is crucial for functional components.

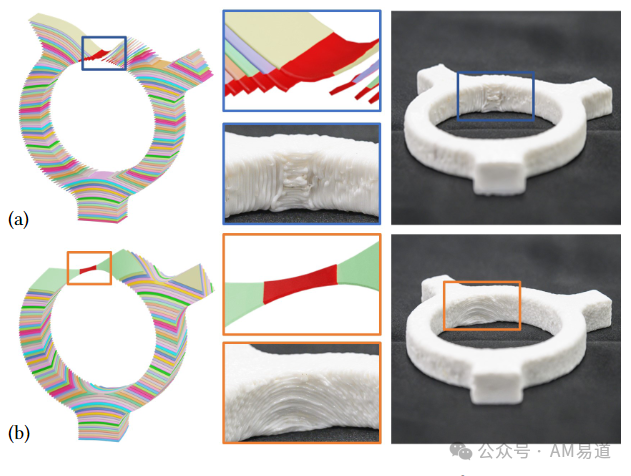

More importantly, the fracture mode has also changed: from breaking at the ear root to breaking at the ear hole, which aligns with the predictions from finite element analysis.The finite element analysis (FEA) results in Figure 10 further confirm that compared to slicing that only considers support-free (SF) requirements, slicing that simultaneously considers both support-free (SF) and strength enhancement (SR) can reduce the maximum strain by 36.8%, which is crucial for functional components. Significant Reduction in Support RequirementsNeural Slicer excels in reducing support requirements.Figure 7 compares the performance of the S³ slicer and Neural Slicer on ring-type models, showing that the surface layers generated by Neural Slicer better avoid overhangs.

Significant Reduction in Support RequirementsNeural Slicer excels in reducing support requirements.Figure 7 compares the performance of the S³ slicer and Neural Slicer on ring-type models, showing that the surface layers generated by Neural Slicer better avoid overhangs. Figure 8 showcases the results of the Tubes model, where Neural Slicer reduced overhang areas by 95% compared to the S³ slicer, meaning that support requirements were nearly completely eliminated.

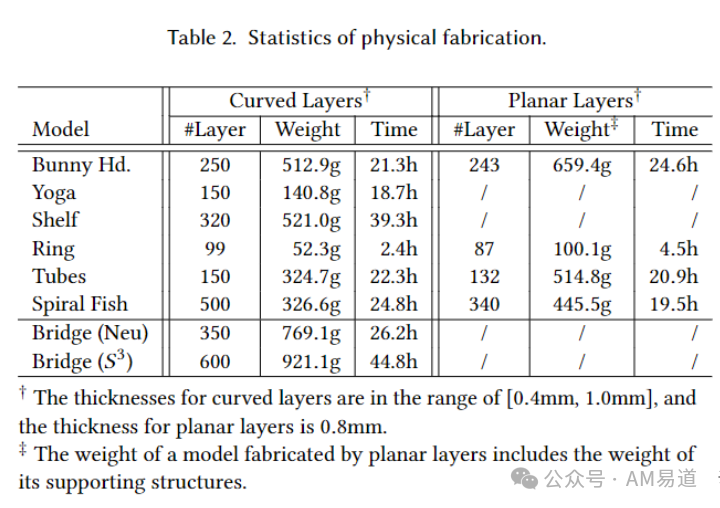

Figure 8 showcases the results of the Tubes model, where Neural Slicer reduced overhang areas by 95% compared to the S³ slicer, meaning that support requirements were nearly completely eliminated. The physical printing statistics in Table 2 also confirm that models printed with surface layers are lighter, have shorter printing times, and maintain or improve mechanical performance compared to models printed with planar layers.

The physical printing statistics in Table 2 also confirm that models printed with surface layers are lighter, have shorter printing times, and maintain or improve mechanical performance compared to models printed with planar layers. Comprehensive Advancement Over Previous TechnologiesNeural Slicer has significant advantages over previous non-planar slicing methods, such as the S³ slicer:It can handle various model representations, including tetrahedral meshes (3D meshes composed of tetrahedra), surface meshes (composed of triangles), skeletons, etc., making it more versatile.The loss function is directly defined in model space rather than deformation space, avoiding the mapping distortion issues shown in Figure 2.

Comprehensive Advancement Over Previous TechnologiesNeural Slicer has significant advantages over previous non-planar slicing methods, such as the S³ slicer:It can handle various model representations, including tetrahedral meshes (3D meshes composed of tetrahedra), surface meshes (composed of triangles), skeletons, etc., making it more versatile.The loss function is directly defined in model space rather than deformation space, avoiding the mapping distortion issues shown in Figure 2. The S³ slicer satisfies support-free requirements in deformation space, which may lead to larger overhang areas when mapped back to model space.It does not require high-quality tetrahedral meshes, reducing computational demands.Neural Slicer achieves better results with far fewer cage mesh elements than the S³ slicer.More importantly, the neural network’s expressive power: the non-linear characteristics of neural networks can model more complex deformations.Readers are encouraged to refer to the original text for specific algorithm principles and details.Practical Applications and Future ProspectsNeural Slicer has been validated on multi-axis 3D printing hardware systems, such as the 6-degree-of-freedom (DOF) ABB IRB 2600 robotic arm combined with a 2DOF ABB A250 positioning system, as shown in Figure 1(d).

The S³ slicer satisfies support-free requirements in deformation space, which may lead to larger overhang areas when mapped back to model space.It does not require high-quality tetrahedral meshes, reducing computational demands.Neural Slicer achieves better results with far fewer cage mesh elements than the S³ slicer.More importantly, the neural network’s expressive power: the non-linear characteristics of neural networks can model more complex deformations.Readers are encouraged to refer to the original text for specific algorithm principles and details.Practical Applications and Future ProspectsNeural Slicer has been validated on multi-axis 3D printing hardware systems, such as the 6-degree-of-freedom (DOF) ABB IRB 2600 robotic arm combined with a 2DOF ABB A250 positioning system, as shown in Figure 1(d). AM Yidao believes that non-planar slicing algorithms will have a profound impact on the 3D printing industry.They can greatly expand the application range of FDM printing, enabling it to handle more complex geometries and functional requirements.By eliminating or reducing support structures, they lower material consumption and printing time, improving production efficiency and sustainability.Finally, the significant enhancement in mechanical performance of printed parts makes FDM printing applicable in high-demand fields such as functional parts and load-bearing structures.

AM Yidao believes that non-planar slicing algorithms will have a profound impact on the 3D printing industry.They can greatly expand the application range of FDM printing, enabling it to handle more complex geometries and functional requirements.By eliminating or reducing support structures, they lower material consumption and printing time, improving production efficiency and sustainability.Finally, the significant enhancement in mechanical performance of printed parts makes FDM printing applicable in high-demand fields such as functional parts and load-bearing structures. Of course, Neural Slicer still has some limitations and room for improvement, such as neglecting the anisotropic effects brought by surface layers (material performance varies in different directions).Integrating anisotropic FEA into the optimization loop may further enhance the mechanical performance of printed parts.Additionally, as mentioned in the article, global collision handling and computational efficiency optimization also need improvement.Not Just Theory: Joshua Bird Turns Non-Planar Slicing into RealityBefore delving into the University of Manchester research team’s Neural Slicer, it is essential to mention another innovator who has made outstanding contributions in the field of non-planar slicing—Joshua Bird.Previously, AM Yidao shared his masterpiece: Cambridge genius boy made a big leap! New 4-axis FDM 3D printing device blueprints + code fully open source, capable of printing overhang angles up to 90 degrees!The S4 slicer (Simple S3 Slicer) he developed brought non-planar slicing technology from academic theory into practical application.S3 Slicer is an earlier optimization-based non-planar slicing algorithm developed by the same research team at the University of Manchester, while Bird’s S4 is a simplification and improvement of S3.Unlike the Neural Slicer discussed in this article, S4 employs a three-step method of “deformation-slicing-inverse deformation”, first deforming the model to eliminate overhangs, then slicing with a traditional slicer, and finally transforming the tool path back to the original shape.Bird’s video showcases stunning application cases, particularly the printing of the inverted Benchy model, which features overhangs exceeding 90°, something impossible with traditional printing.

Of course, Neural Slicer still has some limitations and room for improvement, such as neglecting the anisotropic effects brought by surface layers (material performance varies in different directions).Integrating anisotropic FEA into the optimization loop may further enhance the mechanical performance of printed parts.Additionally, as mentioned in the article, global collision handling and computational efficiency optimization also need improvement.Not Just Theory: Joshua Bird Turns Non-Planar Slicing into RealityBefore delving into the University of Manchester research team’s Neural Slicer, it is essential to mention another innovator who has made outstanding contributions in the field of non-planar slicing—Joshua Bird.Previously, AM Yidao shared his masterpiece: Cambridge genius boy made a big leap! New 4-axis FDM 3D printing device blueprints + code fully open source, capable of printing overhang angles up to 90 degrees!The S4 slicer (Simple S3 Slicer) he developed brought non-planar slicing technology from academic theory into practical application.S3 Slicer is an earlier optimization-based non-planar slicing algorithm developed by the same research team at the University of Manchester, while Bird’s S4 is a simplification and improvement of S3.Unlike the Neural Slicer discussed in this article, S4 employs a three-step method of “deformation-slicing-inverse deformation”, first deforming the model to eliminate overhangs, then slicing with a traditional slicer, and finally transforming the tool path back to the original shape.Bird’s video showcases stunning application cases, particularly the printing of the inverted Benchy model, which features overhangs exceeding 90°, something impossible with traditional printing. In contrast, the Neural Slicer shared in this article adopts a different technical route, utilizing neural networks for direct optimization, offering stronger expressive power and better computational efficiency, albeit with higher implementation complexity.These three algorithms collectively advance non-planar slicing technology, providing different technical solutions for the support-free era of 3D printing.Opening a New Era of Support-Free 3D PrintingNeural Slicer represents a significant breakthrough in the field of multi-axis 3D printing.It combines the powerful expressive capability of neural networks with a meticulously designed multi-objective optimization framework, creating a non-planar slicing method capable of handling complex geometries, requiring no support structures, and significantly enhancing mechanical performance.AM Yidao believes that as these algorithms continue to mature and proliferate, multi-axis non-planar printing is likely to become the mainstream technology of the next generation of 3D printing.It not only addresses the core pain points of current FDM printing but also opens up new application scenarios, from functional prototypes to end-use parts, from consumer products to industrial applications, the potential of multi-axis non-planar printing is gradually being unleashed.When we completely free ourselves from the constraints of support structures, when the strength of printed parts is no longer a limiting factor, when complex geometries are no longer a challenge, what leaps will 3D printing technology achieve?This article shows us not just an algorithm, but a new era of support-free, high-strength, and free-form 3D printing.Article Information:

In contrast, the Neural Slicer shared in this article adopts a different technical route, utilizing neural networks for direct optimization, offering stronger expressive power and better computational efficiency, albeit with higher implementation complexity.These three algorithms collectively advance non-planar slicing technology, providing different technical solutions for the support-free era of 3D printing.Opening a New Era of Support-Free 3D PrintingNeural Slicer represents a significant breakthrough in the field of multi-axis 3D printing.It combines the powerful expressive capability of neural networks with a meticulously designed multi-objective optimization framework, creating a non-planar slicing method capable of handling complex geometries, requiring no support structures, and significantly enhancing mechanical performance.AM Yidao believes that as these algorithms continue to mature and proliferate, multi-axis non-planar printing is likely to become the mainstream technology of the next generation of 3D printing.It not only addresses the core pain points of current FDM printing but also opens up new application scenarios, from functional prototypes to end-use parts, from consumer products to industrial applications, the potential of multi-axis non-planar printing is gradually being unleashed.When we completely free ourselves from the constraints of support structures, when the strength of printed parts is no longer a limiting factor, when complex geometries are no longer a challenge, what leaps will 3D printing technology achieve?This article shows us not just an algorithm, but a new era of support-free, high-strength, and free-form 3D printing.Article Information:

https://dl.acm.org/doi/10.1145/3658212

Open Source Project Information:

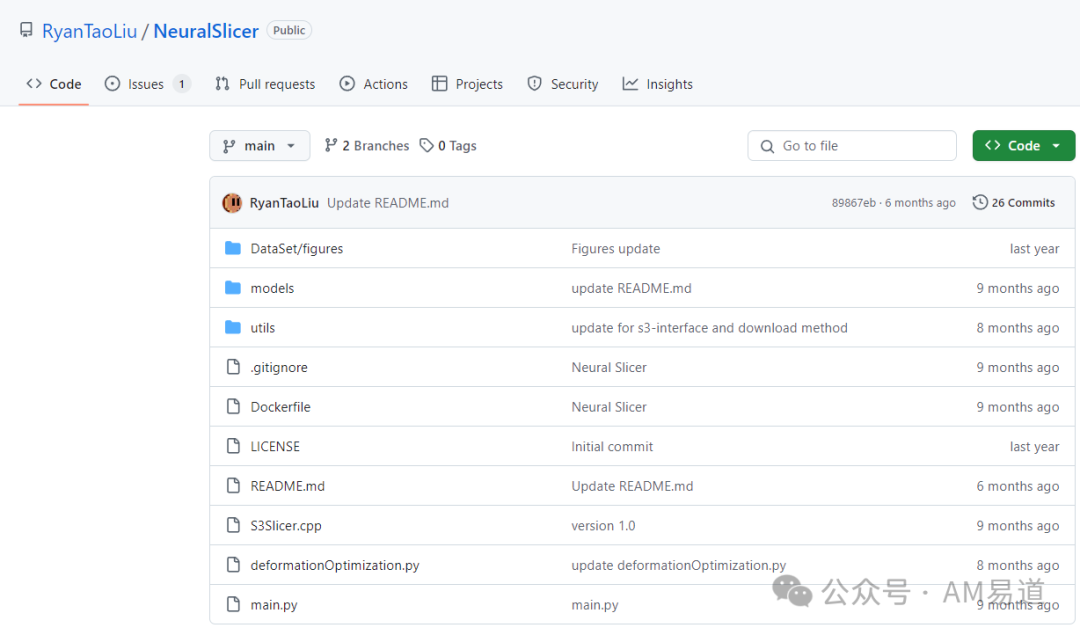

The GitHub repository for the Neural Slicer project provides complete code implementations, datasets, and detailed documentation, allowing anyone to replicate this cutting-edge technology developed by the University of Manchester team.

https://github.com/RyanTaoLiu/NeuralSlicer

The project includes a PyTorch-based neural network optimization framework and provides an interface integration with the S³ slicer, enabling users to achieve support-free multi-axis printing from model representation to final slicing in one go.

By using simple command line parameters, users can control the weights of various optimization objectives such as support-free (SF) and strength enhancement (SR), customizing their printing needs.

The project also comes with several test models (such as spiral fish, earrings, etc.) and detailed installation steps, allowing quick onboarding whether through a conda environment or Docker container.

Corporate Partner Program:Become a partner in the additive industry with AM Yidao, gaining free access to resources for customer acquisition, financing, overseas expansion, and industry-academia-government collaboration.Reader Reminder:Add amyidao to join the reader group (note to join),to obtain original source links or content that is inconvenient to publish, and discuss everything about 3D printing with like-minded readers of AM Yidao,AM Yidao also suggests readers star the public account to receive updates from AM Yidao promptly.Disclaimer:AM Yidao has no commercial cooperation, sponsorship, employment, or other interests with the companies mentioned in the text.AM Yidao ImageVideo clips are sourced from the internet for auxiliary reading purposes only, with no commercial intent.All rights belong to the original author; if any infringement occurs, please contact the rights holder promptly, and we will delete it immediately. The copyright of images in this article belongs to the copyright holder, and the AM Yidao watermark is automatically added for auxiliary reading, not representing ownership of the image copyright. For image usage, please consult the relevant copyright holders. AM Yidao articles do not constitute any investment advice, and AM Yidao is not responsible for any direct or indirect losses caused by the use of the information in this article.

Corporate Partner Program:Become a partner in the additive industry with AM Yidao, gaining free access to resources for customer acquisition, financing, overseas expansion, and industry-academia-government collaboration.Reader Reminder:Add amyidao to join the reader group (note to join),to obtain original source links or content that is inconvenient to publish, and discuss everything about 3D printing with like-minded readers of AM Yidao,AM Yidao also suggests readers star the public account to receive updates from AM Yidao promptly.Disclaimer:AM Yidao has no commercial cooperation, sponsorship, employment, or other interests with the companies mentioned in the text.AM Yidao ImageVideo clips are sourced from the internet for auxiliary reading purposes only, with no commercial intent.All rights belong to the original author; if any infringement occurs, please contact the rights holder promptly, and we will delete it immediately. The copyright of images in this article belongs to the copyright holder, and the AM Yidao watermark is automatically added for auxiliary reading, not representing ownership of the image copyright. For image usage, please consult the relevant copyright holders. AM Yidao articles do not constitute any investment advice, and AM Yidao is not responsible for any direct or indirect losses caused by the use of the information in this article.