Glass, as one of the oldest industrial materials used by humans, has undergone an evolution in its manufacturing process over thousands of years, transitioning from blowing, casting to float glass. However, traditional methods face bottlenecks in producing complex structures and functional doping. The emergence of 3D printing technology has opened a new era for glass manufacturing. Through layer-by-layer digital forming, scientists have not only achieved the free construction of complex geometric structures but also created intelligent glass materials with special optical properties.

New Discovery: Metal Doping 3D glass achieves precise control of optical properties.

Recently, a team from Harbin Institute of Technology developed an LCD 3D printing technology that showcases revolutionary breakthroughs. Researchers used a photosensitive slurry with a silica content of 53% and successfully prepared Cr³⁺ and Co²⁺ doped fused quartz glass through a process of de-fatting, soaking, and sintering. Experimental data shows:

|

Doping Type |

Solution Concentration (mol/cm³) |

Glass Concentration (μmol/cm³) |

Characteristic Absorption Wavelength (nm) |

Coloring Effect |

|

Cr³⁺ |

2.5 |

2.042 |

471 (blue light), 660 (red light) |

Green transparent |

|

Co²⁺ |

15 |

12.249 |

597 (yellow light), 662 (red light) |

Blue transparent |

The highlights of this technology:

- → Achieved efficient penetration of metal salt solutions by controlling the porosity of the de-fatting parts at 32.7% (average pore diameter 33.57nm).

- → After sintering at 1280℃, the glass transmittance reached 88%, comparable to commercial KN7980 fused quartz.

- → In the 660nm red light band, the absorption rate of Cr³⁺ doped glass reached 80%, showing potential as an optical filter.

Based on the above new discoveries, we will also discuss the current mainstream 3D printing glass processes.

We have created a comparison table for your reference.

|

Process |

Resolution (μm) |

Transmittance |

Surface Roughness (nm) |

Shrinkage Rate |

Bending (MPa) |

Applicable Scenarios |

|

FDM Fused Deposition Modeling |

100-400 |

82% |

Unpolished >1000 |

25-43% |

67-95 |

Large decorative pieces, microfluidic chips |

|

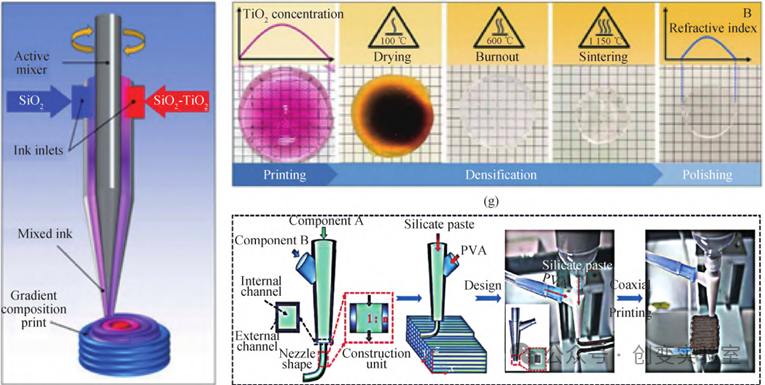

DIW Direct Ink Writing |

50-200 |

85-88% |

Polished 300-600 |

40-47% |

– |

Gradient refractive index lenses |

|

PBF Powder Bed Fusion |

100-300 |

65-75% |

Unpolished >5000 |

35-40% |

– |

Industrial structural parts |

|

DED Directed Energy Deposition |

200-500 |

92% |

Native 200-500 |

15-20% |

– |

Aerospace components |

|

SLA Stereolithography |

10-50 |

88% |

Post 2000 |

28% |

– |

Micro-optical components |

|

DLP Digital Light Processing |

20-100 |

90-92% |

Native 100 |

23-56% |

262 |

Complex structural transparent parts |

|

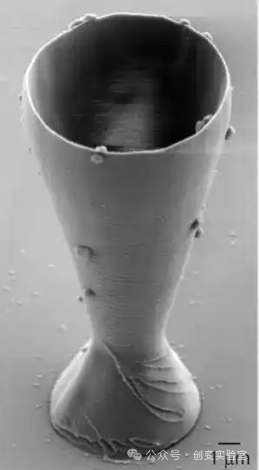

TPP Two-Photon Polymerization |

0.4-1.0 |

93% |

Native 5.7 |

15-27% |

– |

Nanoscale optical devices |

|

UV-DIW UV-Assisted Direct Ink Writing |

50-150 |

– |

Not published |

– |

– |

Multi-material composite structures |

|

CAL Micro-Scale Computed Axial Lithography |

<10 |

90% |

Sub-micron level |

– |

– |

Microfluidic channels |

|

TPP-DUV Two-Photon Polymerization – Deep Ultraviolet Conversion Technology |

0.2-0.5 |

91% |

Native ≤5 |

17% |

– |

Micro-optical devices |

Summary of Findings:

- TPP technology leads the precision race with sub-micron resolution (400nm truss structure) and 5.7nm surface roughness.

- DLP process achieves the best balance between transmittance (92%) and strength (262MPa).

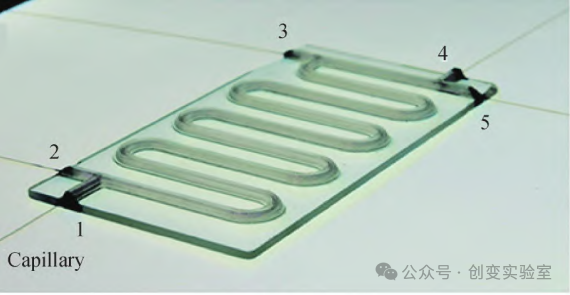

- FDM has lower precision but can print microchannels with a diameter of 0.4mm, offering unique advantages in the medical device field.

At the same time, we have found recent advancements in 3D printing glass in the following areas:

Optical Field

- The German KIT Institute achieved a refractive index gradient change of 0.02/mm through DLP printed GRIN lenses.

- Cr³⁺ doped glass made a 471nm blue light filter, showing great potential in laser protection.

Microfluidic Chips

- The Nguyen team manufactured glass chips with a channel width of 140μm using DIW technology, capable of withstanding 300℃ high-temperature sterilization.

- The Israeli team developed an FDM microfluidic device that can complete complex channel printing in 30 minutes.

Art and Architecture

- A Swiss artist created a glass sculpture titled “Maze of Light” containing 5000 crystal facets using SLA technology.

- The MIT team 3D printed micron-level glass cups (diameter < a hair strand), showcasing the limits of nanomanufacturing.

Summary of 3D Printing Glass Technology

The application prospects of 3D printing technology in glass manufacturing are broad. Although there are still many challenges, these issues will gradually be resolved with continuous technological advancements and optimizations.

Expansion of Material Types

Currently, 3D printing glass materials mainly consist of silica-based glasses such as quartz, but sulfide glasses, phosphate glasses, and sodium-calcium glasses are also gradually being applied in 3D printing. In the future, 3D printing technology will continue to promote the preparation of glass materials at lower temperatures. For example, the TPP process can achieve quartz glass forming at 650℃.

Optimization of Processes

Technologies such as DIW, SLA, DLP, and TPP can all produce functional glass devices with precise feature resolution and ideal surface quality. However, these technologies still have room for improvement, including optimizing photopolymer formulations, controlling post-processing temperature curves to eliminate stress effects on precision or cracks, and exploring the impact of different glass formulations and particle shapes and sizes on forming precision. For example, TPP printing of a 1cm³ structure takes 10 hours, making it difficult for mass production; the DIW process has a shrinkage rate of over 40%, resulting in a qualified rate of less than 60% for precision devices.

Expansion of Application Fields

3D printing technology can ensure high transparency, low surface roughness, high precision, and the forming of small-sized components in glass. The printed glass has good application prospects in optical components, microfluidic chips, and gradient refractive index (GRIN) optics. For example, the DIW method can prepare glass optical components with gradient refractive indices and multiple materials, while TPP, SLA, micro-CAL, and TPP-DUV technologies can already produce micro-structured lenses and complex fine-structured microfluidic glass devices.

Future Prospects

- 1. Multi-material co-printing: UV-DIW technology has achieved synchronous printing of glass and metal;

- 2. Smart responsive glass: Metal doping pathways indicate directions for thermosensitive and photochromic glass;

- 3. Space manufacturing: NASA is testing 3D printing of glass in zero-gravity environments for lunar base construction. Similar plans exist in our country to use lunar soil for 3D printing. Can you guess what the main component of lunar soil is?

3D printing technology has brought revolutionary changes to the glass manufacturing field. It not only enables the digital manufacturing of complex structures but also provides new possibilities for the functionalization and performance optimization of glass materials. From material extrusion to stereolithography, various 3D printing technologies have their advantages and are suitable for different application scenarios. With continuous technological advancements and optimizations, 3D printing glass materials will play unique advantages in more fields, injecting new vitality into the traditional glass manufacturing industry.