Recently, Carnegie Mellon University reported a new ceramic 3D printing technology based on aerosol jet printing (3D-AJP), which can be used to manufacture high-performance ceramic materials with complex microstructures. This technology achieves binder-free, support-free nano-printing to create complex ceramic structures at micro-scale (minimum feature size of 20 micrometers) with extremely low shrinkage rates (2-6%) after sintering. The research demonstrates the potential applications of this technology in various fields such as photocatalysis, biosensing, and microelectronics packaging.

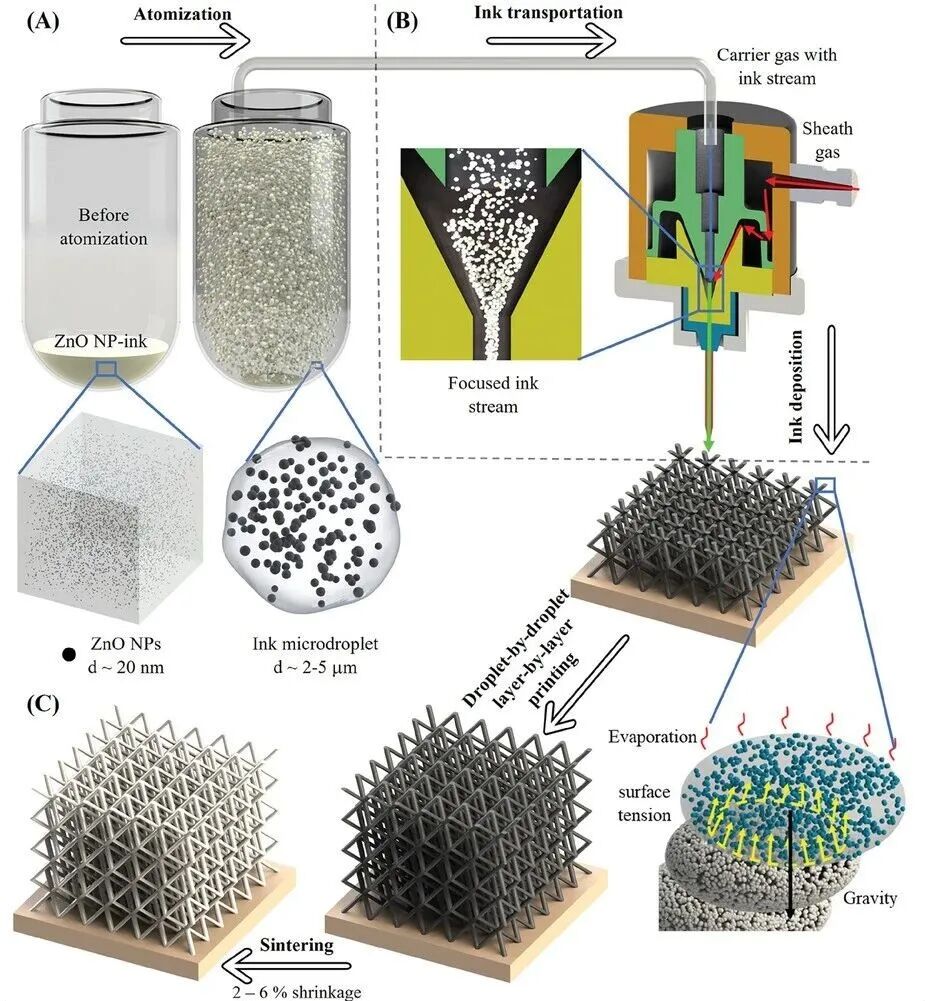

3D aerosol jet printing (3D-AJP) schematic: aerosol jet printing of complex three-dimensional ceramic microstructures with nearly zero shrinkage. A) The ultrasonic atomizer in the AJ nanoparticle printer atomizes the ink based on zinc oxide (ZnO) nanoparticles, with an enlarged image showing the nanoparticles in the ink bottle (diameter ≈ 20 nanometers) and individual droplets. B) The aerosol (mist) is transported to the deposition nozzle through a piping system using inert gas. The enlarged image shows the loosely arranged ink flow focused onto the substrate by the sheath gas. C) Rapid drop-by-drop freeform printing without support. The enlarged image illustrates the mechanism for constructing inclined structures without auxiliary support. The extremely low shrinkage observed after sintering proves its near-net-shape manufacturing effectiveness.The core of the 3D-AJP technology is the use of aerosol jet printing to precisely deposit nanoparticle ink into complex three-dimensional microstructures. It employs nearly binder-free nanoparticle ink, avoiding the high shrinkage rates and structural defects caused by binder removal in traditional manufacturing. This technology can achieve complex structures with a minimum feature size of 20 micrometers, such as micro-columns, spirals, and lattices, with aspect ratios up to 30:1. Additionally, it has multi-material printing capabilities, allowing the integration of different ceramic materials (such as zinc oxide, titanium dioxide, and zirconia) within the same structure.

3D aerosol jet printing (3D-AJP) schematic: aerosol jet printing of complex three-dimensional ceramic microstructures with nearly zero shrinkage. A) The ultrasonic atomizer in the AJ nanoparticle printer atomizes the ink based on zinc oxide (ZnO) nanoparticles, with an enlarged image showing the nanoparticles in the ink bottle (diameter ≈ 20 nanometers) and individual droplets. B) The aerosol (mist) is transported to the deposition nozzle through a piping system using inert gas. The enlarged image shows the loosely arranged ink flow focused onto the substrate by the sheath gas. C) Rapid drop-by-drop freeform printing without support. The enlarged image illustrates the mechanism for constructing inclined structures without auxiliary support. The extremely low shrinkage observed after sintering proves its near-net-shape manufacturing effectiveness.The core of the 3D-AJP technology is the use of aerosol jet printing to precisely deposit nanoparticle ink into complex three-dimensional microstructures. It employs nearly binder-free nanoparticle ink, avoiding the high shrinkage rates and structural defects caused by binder removal in traditional manufacturing. This technology can achieve complex structures with a minimum feature size of 20 micrometers, such as micro-columns, spirals, and lattices, with aspect ratios up to 30:1. Additionally, it has multi-material printing capabilities, allowing the integration of different ceramic materials (such as zinc oxide, titanium dioxide, and zirconia) within the same structure.

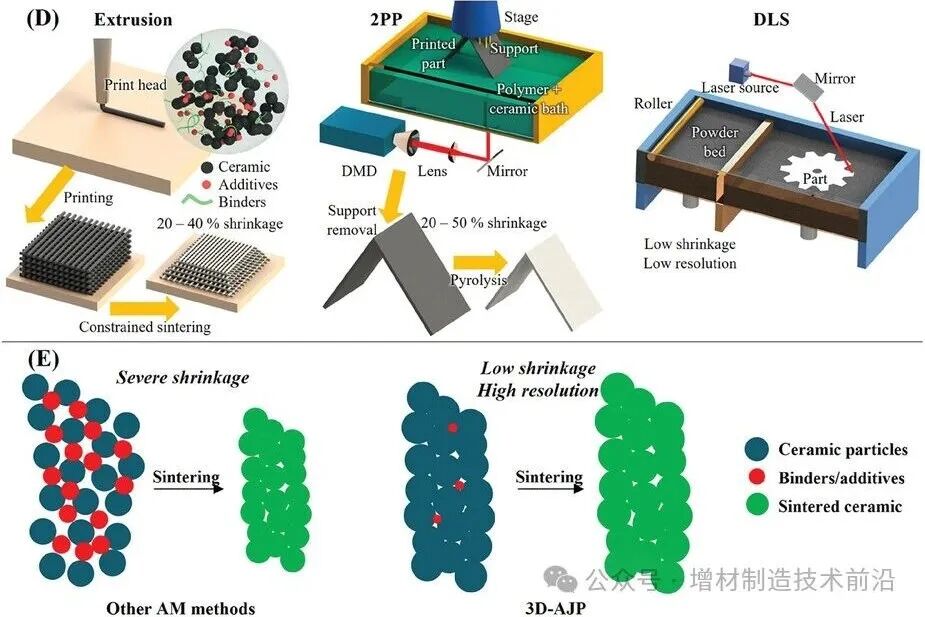

Manufacturing ceramics through other 3D printing technologies (such as extrusion printing, 2PP, and DLS). Demonstrating the precursor inks used in ceramic manufacturing with high binder content (left) and minimal binder content (right)

The linear shrinkage rate after sintering for this technology is only 2-6%, significantly lower than traditional techniques (such as 15-43% in 3D printing). Furthermore, the 3D-AJP technology can rapidly manufacture complex ceramic structures without complicated post-processing steps.This research showcases the application potential of the 3D-AJP technology in multiple fields.

Comparison of CAD design and manufacturing of zinc oxide (ZnO) micro-lattices achieved through 3D aerosol jet printing technology. Optical images of high aspect ratio micro-lattices (height of 1 cm, width of 600 micrometers). Top view of different ceramic materials (i.e., zirconia ZrO₂) micro-lattices (left) and inclined scanning electron microscope (SEM) view (right)

In the field of photocatalysis, researchers manufactured ZnO (zinc oxide) micro-lattice structures and used them for photocatalytic degradation of methyl orange dye. The results showed that compared to traditional bulk ZnO, the ZnO micro-lattices produced by 3D-AJP exhibited a 400% increase in photocatalytic efficiency, demonstrating significant performance improvement.In the biosensing field, a sensor was manufactured using 3D-AJP technology to detect the breast cancer biomarker Her2. This sensor can detect the Her2 biomarker within 22 seconds, with a detection limit as low as 0.0193 femtomoles (fm), showing extremely high sensitivity.

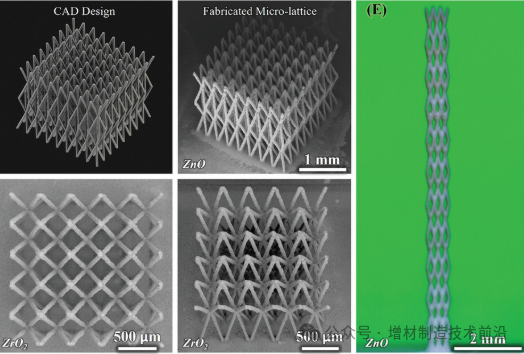

Complex single-material and dual-material ceramic microstructures produced by aerosol jet nano-printing. A) CAD design of multi-spiral microstructures (top) and scanning electron microscope (SEM) images (bottom); B) CAD design of pyramid-shaped micro-lattices (top) and SEM images (bottom); C) CAD design of wavy micro-walls made of zinc oxide (ZnO) (top) and SEM images (bottom). All scale bars are 500 micrometers. D) Printed dual-material pyramid-shaped micro-lattice (left) and energy dispersive X-ray spectroscopy (EDX) analysis showing zirconium (Zr) and zinc (Zn) on different printed layers (right). E) Other dual-material micro-lattices, including titanium dioxide (TiO₂) on top and ZnO on the bottom, with EDX analysis confirming their composition. Also shown is another dual-material structure with TiO₂ on top and zirconia (ZrO₂) on the bottom. F) Mixed ceramic materials containing alumina (Al₂O₃), TiO₂, and ZnO, with EDX analysis showing uniform distribution of titanium (Ti), aluminum (Al), and zinc (Zn) within a single lattice.

Moreover, the 3D-AJP technology also demonstrates the ability to integrate various ceramic materials such as ZnO, TiO2, and ZrO2 within the same structure, providing new possibilities for the manufacture of high-performance catalysts, sensors, and optoelectronic devices.In summary, the 3D-AJP technology achieves high-precision manufacturing of complex ceramic microstructures through binder-free nano-printing processes, with extremely low shrinkage rates after sintering. This technology not only demonstrates significant performance improvements in photocatalysis and biosensing fields but also opens new possibilities for manufacturing multi-material composite structures. The 3D-AJP technology is expected to find widespread applications in microelectronics packaging, structural materials, biomedical sensing, thermal barrier coatings, and filtration technologies, paving the way for the manufacture of high-performance ceramic materials.Recommended reading: 3D-AJP: Fabrication of Advanced Microarchitected Multimaterial Ceramic Structures via Binder-Free and Auxiliary-Free Aerosol Jet 3D NanoprintingNote: You are welcome to join the PhD and Master’s exchange QQ group (248112776)