The role of the FAI first article tester is to conduct comprehensive testing on the first product produced before mass production begins, ensuring it meets quality standards before large-scale manufacturing starts. This mechanism effectively reduces the risk of incorrect items, lowers the probability of errors, and improves the overall quality of production. Through first article testing, the product manufacturing process can be pre-controlled, preventing the occurrence of large batches of defective products.

Working Principle of the FAI First Article Tester:

The FAI first article tester typically consists of an LCR bridge integrated with a set of FAI software. It imports the product BOM, coordinates, and Gerber files into the system, where employees use dedicated fixtures to measure the first article sample components. The system automatically recognizes the customer BOM and CAD layout, generates the testing program, and displays the test results through graphics or voice, reducing mismeasurement caused by human negligence.

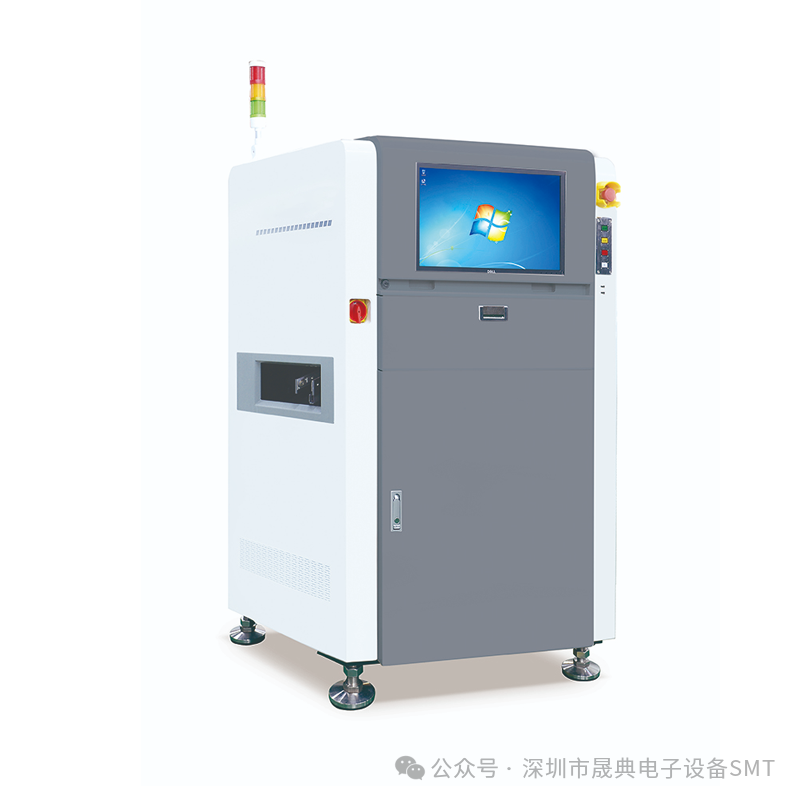

(Shengdian FAI First Article Tester)

(Shengdian FAI First Article Tester)

Automated Optical Inspection Equipment (AOI) is a type of inspection equipment based on optical principles, primarily used to detect defects in various manufacturing processes. AOI equipment automatically scans the object being inspected using cameras, captures images, and then compares the test results with qualified parameters in the database. It identifies defects through image processing technology and displays them on a monitor or through automatic marking for maintenance personnel to rectify.

Working Principle of AOI Equipment

The working principle of AOI equipment mainly includes the following steps:

Image Acquisition: The equipment captures the reflected light image of the inspected object using a photoelectric conversion photography system (such as photodiodes) and an illumination system.

Data Processing: The acquired image data is analyzed and compared through an image processing system to identify defects.

Defect Reporting: The detected defects are displayed on a monitor or through automatic marking for maintenance personnel to rectify.

(Shengdian Fully Automatic Optical Inspection Equipment)

The Solder Paste Thickness Tester (SPI) is a device used to detect and analyze the quality of solder paste printing, primarily used in SMT (Surface Mount Technology) processes to ensure the thickness, uniformity, and consistency of solder paste, thereby enhancing product quality and production efficiency.

Classification and Functions of Solder Paste Thickness Testers

Solder paste thickness testers can be classified into two types: 2D and 3D:

2D Solder Paste Thickness Tester: It can only measure the height of solder paste at a specific point, is relatively simple to operate, but has a larger human error margin.

3D Solder Paste Thickness Tester: It can measure the solder paste height across the entire pad, reflecting the true solder paste thickness, and can automatically focus through a computer, providing more accurate measurement data.

(Shengdian SPI Solder Paste Thickness Tester)