Waterproof Methods for PCBA

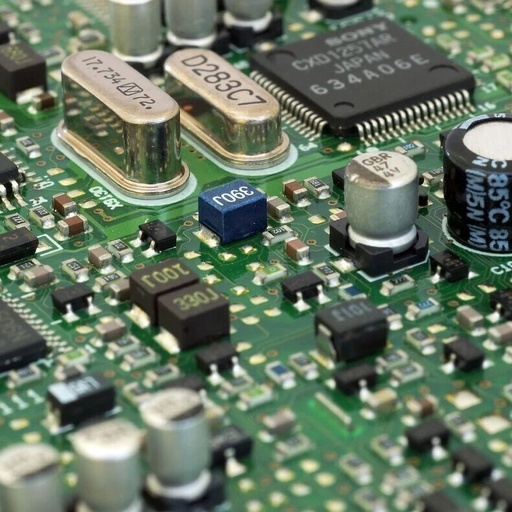

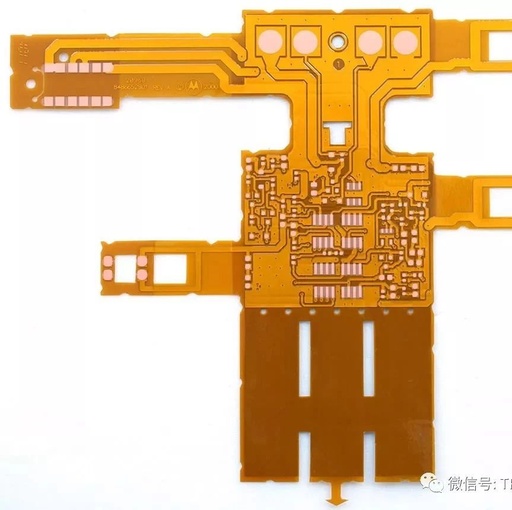

Opinion / Champion This is the68th original content from the Watt Product Design public account. ▪ Potting WaterproofingCurrently, the most common method for potting waterproofing is the use of epoxy resin potting glue, which is used for potting electronic product modules, allowing the entire PCB to be encapsulated, thus providing waterproof, moisture-proof, salt spray-proof, mold-proof, … Read more