Analysis of Defects in PCBA Soldering

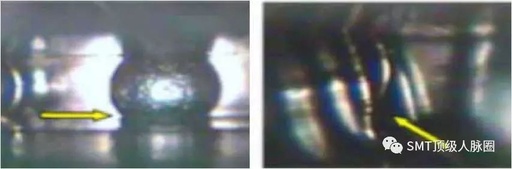

During the production process of PCBA soldering, operational errors can easily lead to defects such as: cold solder joints, short circuits, component lifting, missing components, solder balls, component misalignment, excessive solder, incorrect components, cold soldering, reverse soldering, white/reverse side issues, misalignment, component damage, insufficient solder, excessive solder, solder sticking to gold fingers, and glue overflow. … Read more