When designing electronic products, it is often necessary to evaluate hardware costs. What components make up hardware costs? They mainly consist of the prices of components, PCBs, and SMT, which together constitute the cost of PCBA. In other words, calculating hardware costs primarily involves calculating the cost of PCBA. Let’s learn about the methods for calculating PCBA costs.

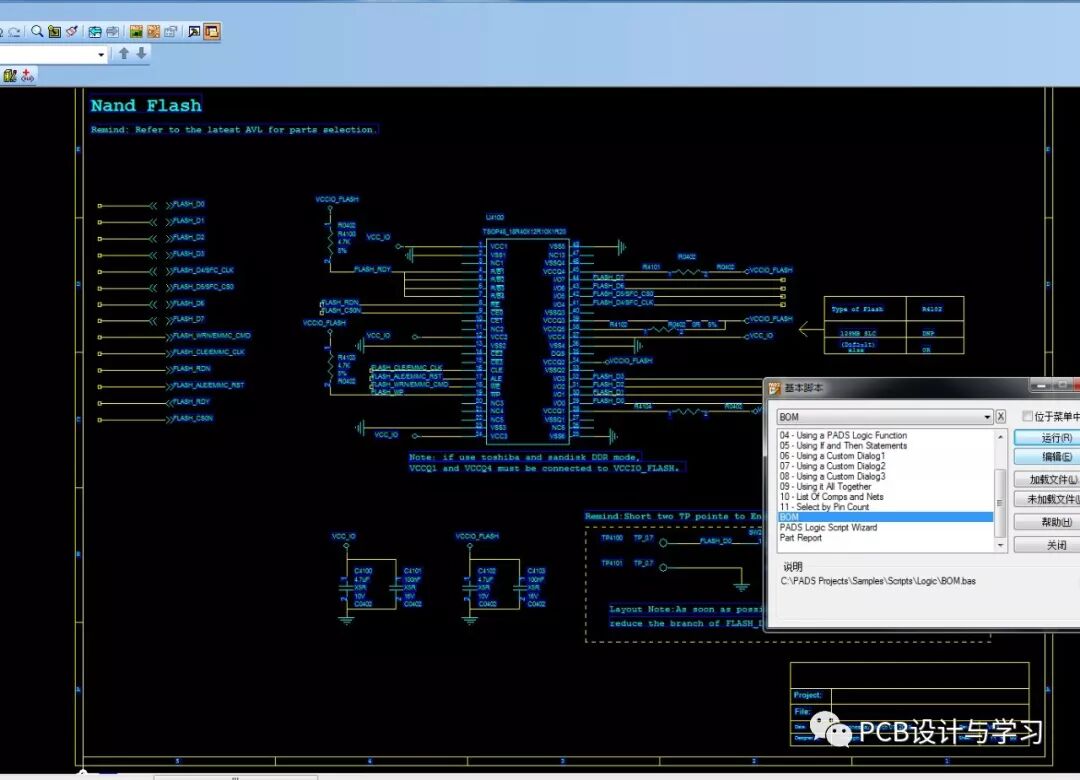

1. First, open the schematic and export the corresponding BOM.

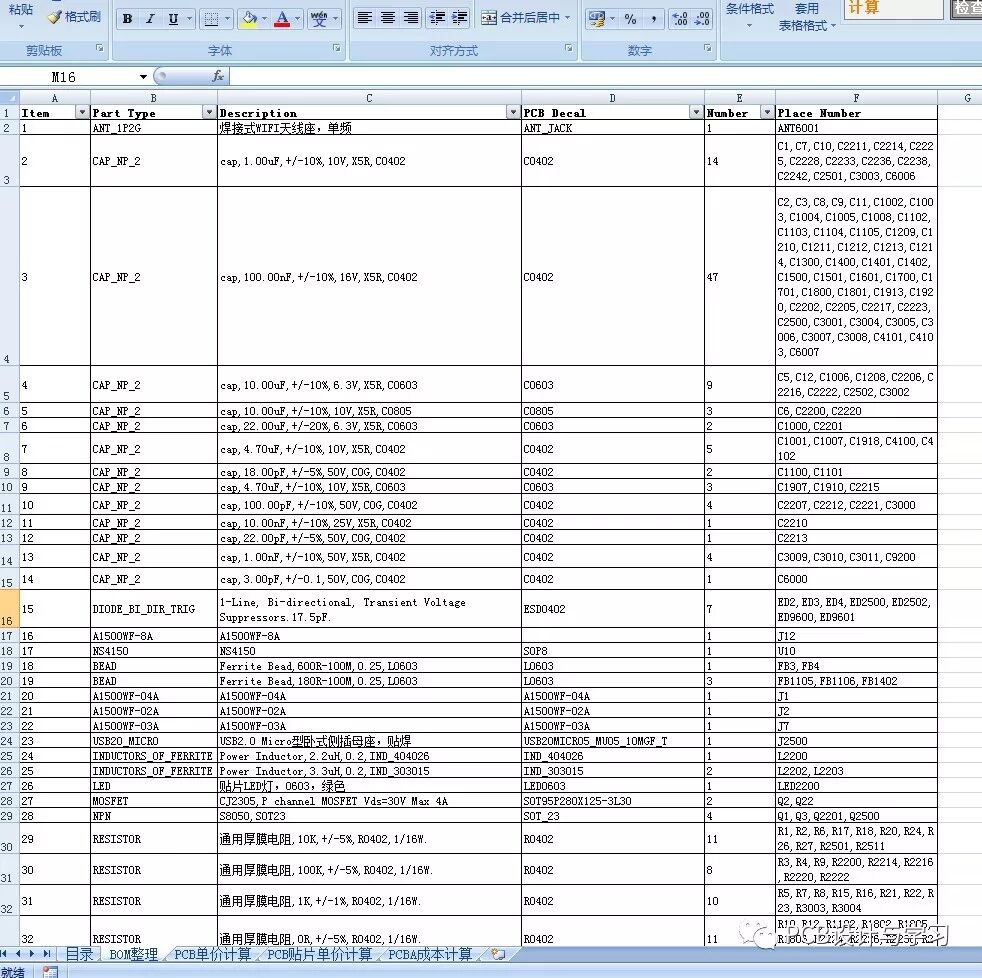

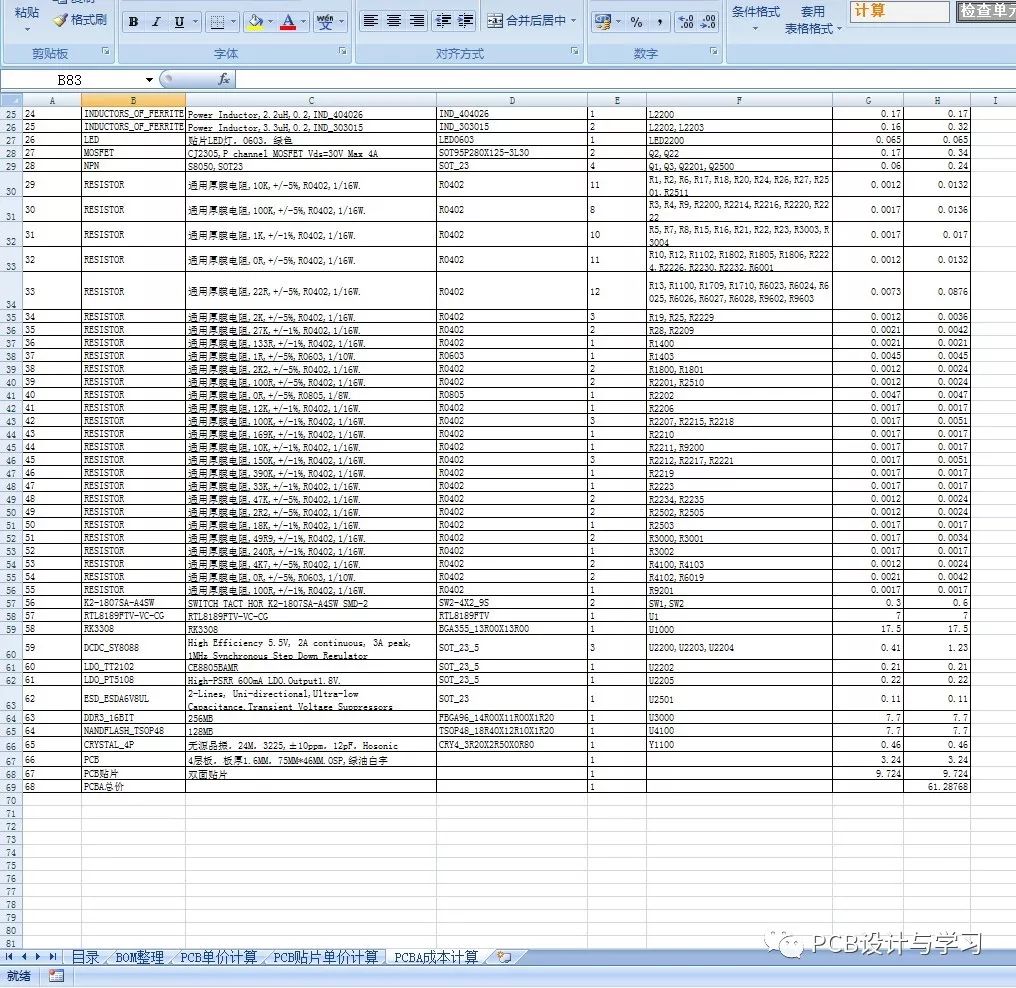

2. After exporting the BOM, organize it by categorizing similar components and counting the quantity of each category. This will be used later to calculate the costs of components and surface mount technology (SMT).

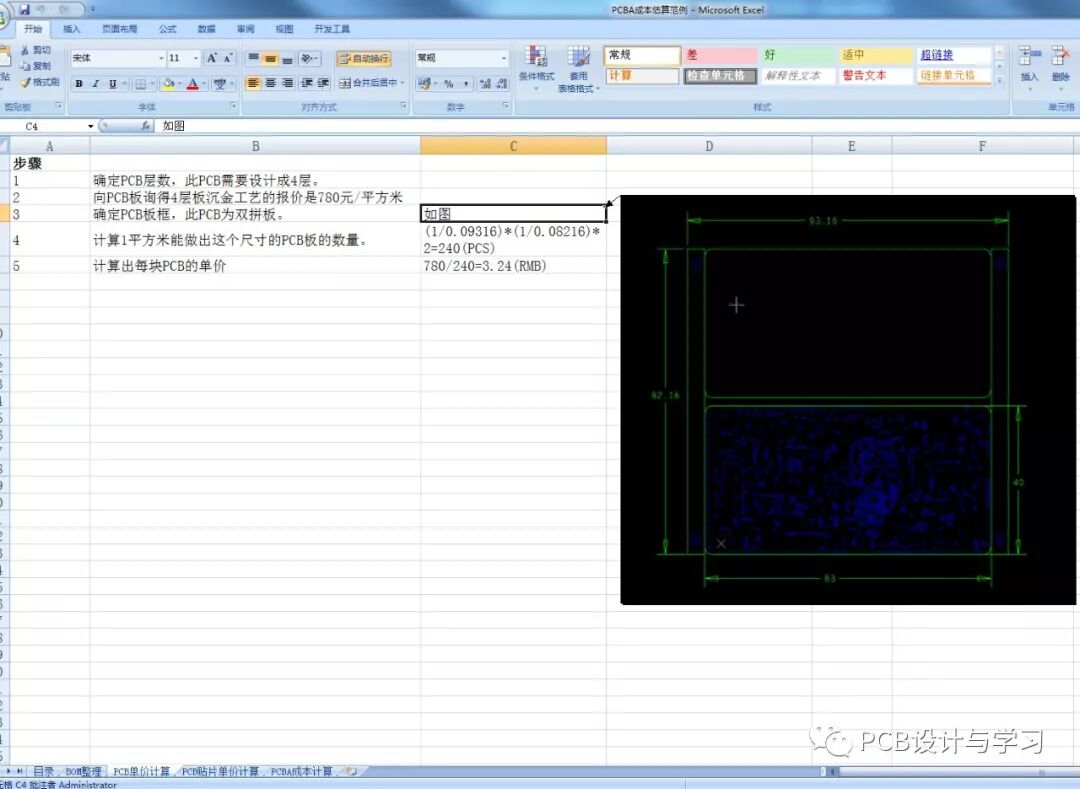

3. Calculate the cost of the PCB by following these steps. First, determine the price per square meter of the PCB, then calculate how many PCBs can be produced from the material of one square meter. Finally, divide the price per square meter of the PCB by the number of PCBs that can be produced from that area to obtain the unit price of the PCB.

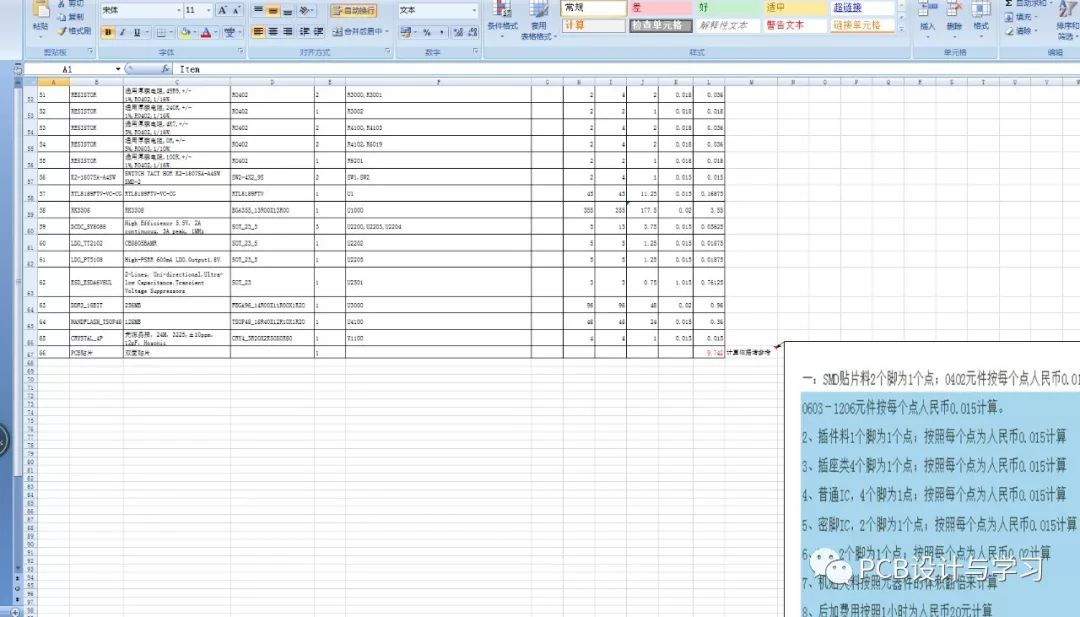

4. Calculate the cost of PCB assembly. The assembly cost is calculated based on the number of pins, so first, count the pins of the components. The unit price varies for different types of pins, and the calculation is done as follows.

5. Finally, calculate the total cost of the PCBA, as shown in the figure below.

If you are interested in this PCBA cost estimation reference case, you can reply “PCBA cost estimation reference case” on the public account homepage to obtain the download link, or download it from the group.