During visual inspection (non-sectioning), voids in the copper layer and coating layer of the hole (void) are common defects. Voids identified during visual inspection refer to areas exposing the substrate material, while voids identified through section analysis refer to areas below the minimum thickness specification, indicating a fundamental difference between the two.

Different grades of products have varying requirements for the plating and coating layers of the hole, as detailed in Table1 (IPC-6012F).

Table 1 Specifications for Voids in Hole Coating Layers (Visual Inspection)

|

Material |

Grade 1 |

Grade 2 |

Grade 3 |

|

Copper |

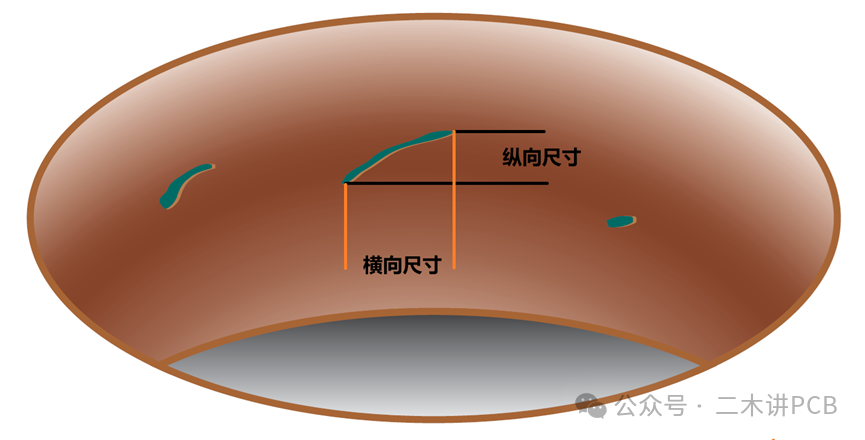

1. Number of voids in the hole ≤3 2. Number of holes with voids ≤10% 3. Longitudinal size of voids ≤ hole height ×10% 4. Lateral size of voids ≤ hole circumference ×1/4 |

1. Number of voids in the hole ≤1 2. Number of holes with voids ≤5% 3. Longitudinal size of voids ≤ hole height ×5% 4. Lateral size of voids ≤ hole circumference ×1/4 |

Not allowed |

|

Coating Layer |

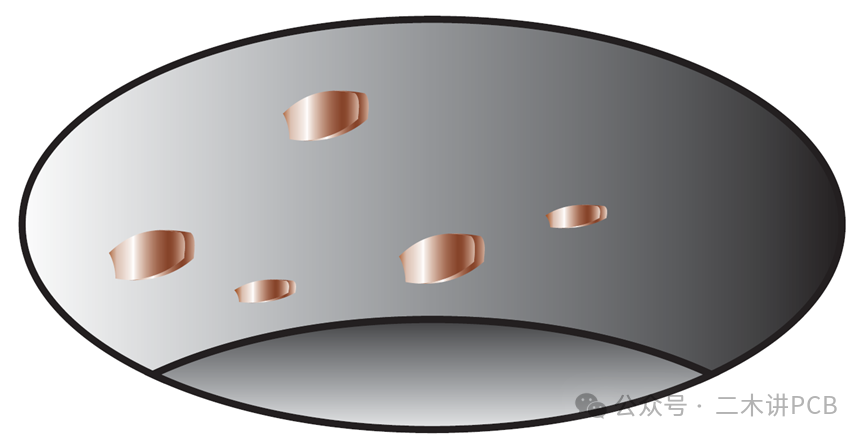

1. Number of voids in the hole ≤5 2. Number of holes with voids ≤15% 3. Longitudinal size of voids ≤ hole height ×10% 4. Lateral size of voids ≤ hole circumference ×1/4 |

1. Number of voids in the hole ≤3 2. Number of holes with voids ≤5% 3. Longitudinal size of voids ≤ hole height ×5% 4. Lateral size of voids ≤ hole circumference ×1/4 |

1. Number of voids in the hole ≤1 2. Number of holes with voids ≤5% 3. Longitudinal size of voids ≤ hole height ×5% 4. Lateral size of voids ≤ hole circumference ×1/4 |

Figure1 Voids in the Copper Plating Layer of the Hole (Exposing the Substrate Material)

Figure2 Voids in the Coating Layer of the Hole (Exposing the Substrate Copper)