Today, I have gathered some ideas and methods on how to master PLC programming. I hope that after accepting this recommendation, everyone can have a general learning approach to PLC programming and independently apply PLCs to complete programming.

1. Basic Hardware Knowledge

Before programming, it’s essential to understand some basic hardware knowledge. It’s best to start with hardware selection and schematic drawing. Once you clarify the types of inputs and outputs, and the selection of analog quantities, it will be easier to start programming. Familiarizing yourself with basic hardware circuits will help you find that ladder diagrams can correspond well with these hardware circuits.

2. Understand PLC Programming Methods

Linear programming, modular programming, and structured programming. For Siemens PLCs, structured programming is primarily used, but linear and modular programming can also be employed. Structured programming requires a certain structured programming mindset.

If you want to master Siemens PLC quickly, it’s recommended to first learn linear or modular programming. Gradually experience structured programming during the learning process.

3. Practice

Practice a lot; having someone guide you or taking advanced classes will generally be faster than self-study, but it’s not absolute. First, buy a book about PLCs, then have a PLC on hand. Based on the examples in the book, work on a small project to implement a function, independently create a PLC project. The Siemens S7-200 series PLC is very suitable for beginners and relatively easy to use.

Today’s PLC software is designed very well. If you have hardware, that’s better. If not, install a software simulator to familiarize yourself with basic operations, and observe the changes in PLC input and output. Before fully validating the program, it’s recommended to disconnect the load and only connect it after all IO and analog tests are completed.

4. Process

The focus of PLC programming is to simulate the original work process, completing the control process through program execution. Therefore, the core content is the program description of the process. It is essential to master PLC programming languages and basic function implementations. PLC languages include ladder diagrams, statement lists, and function block diagrams.

The most commonly used is the ladder diagram, which is suitable for basic logical descriptions. The statement list is suitable for data processing but is relatively harder to understand. Function block diagrams are suitable for step-type state function descriptions and are not used as frequently. For self-study, you need to install the corresponding software; different manufacturers have many differences, but they are similar.

Understanding how devices operate, what information needs to be read, how to control field devices, and how to achieve the best control effect requires a close understanding of the field processes.

5. Basic Automation Knowledge

1. Hardware knowledge of process instruments, including sensors, transmitters (secondary instruments), and the PLC itself, which is the foundation of building a control system; for example, two-wire, four-wire systems, current, voltage, PT100, corresponding physical ranges, vacuum conversion, etc.

2. Process control theory, including the principles and applications of various control models, among which the most important are two-position control and PID control models. PID control is currently the most widely used process control method and is highly variable. It is essential to understand the principles and know how to adjust parameters.

6. Good Programming Habits

1. Variable naming, function block naming, timer naming should follow certain principles for readability;

2. Familiarize yourself with the basic commands of the software;

3. Write common program blocks, such as common blocks for valves and motors;

4. Reasonably allocate main programs, subprograms, and timer interrupt programs;

5. Reasonably allocate data blocks, timers, counters, and memory variables, ensuring variable positions do not overlap.

7. Internal Mechanisms of Software

Every software has its differences, but basic elements should include:

1. Understanding instruction accumulators, status words, and other contents.

2. The composition of instructions and the meanings of various parts, whether it’s high-level language if-then-else statements or PLC instructions like A, AN, JNB, need to be clarified;

3. Understanding several addressing methods. This is very important for microcontrollers; for PLCs, knowing more helps with complex programming.

4. Understanding data formats, paying attention to high and low bit distributions, which is crucial, especially when communicating with third parties.

5. Familiarity with several common registers and storage areas, such as DB, M, I, Q, etc.

In summary, regularly review others’ programs, extract the essence, and expand your knowledge from simple to complex (because PLC functionalities are quite powerful, involving not only control but also communication, etc.).

According to my understanding, many people encounter a problem while learning PLCs: they can independently write some simple programs, but when it comes to developing for a specific set of equipment, they often don’t know how to start. What should be done?

Source: Internet, if there is any infringement, please contact to delete!

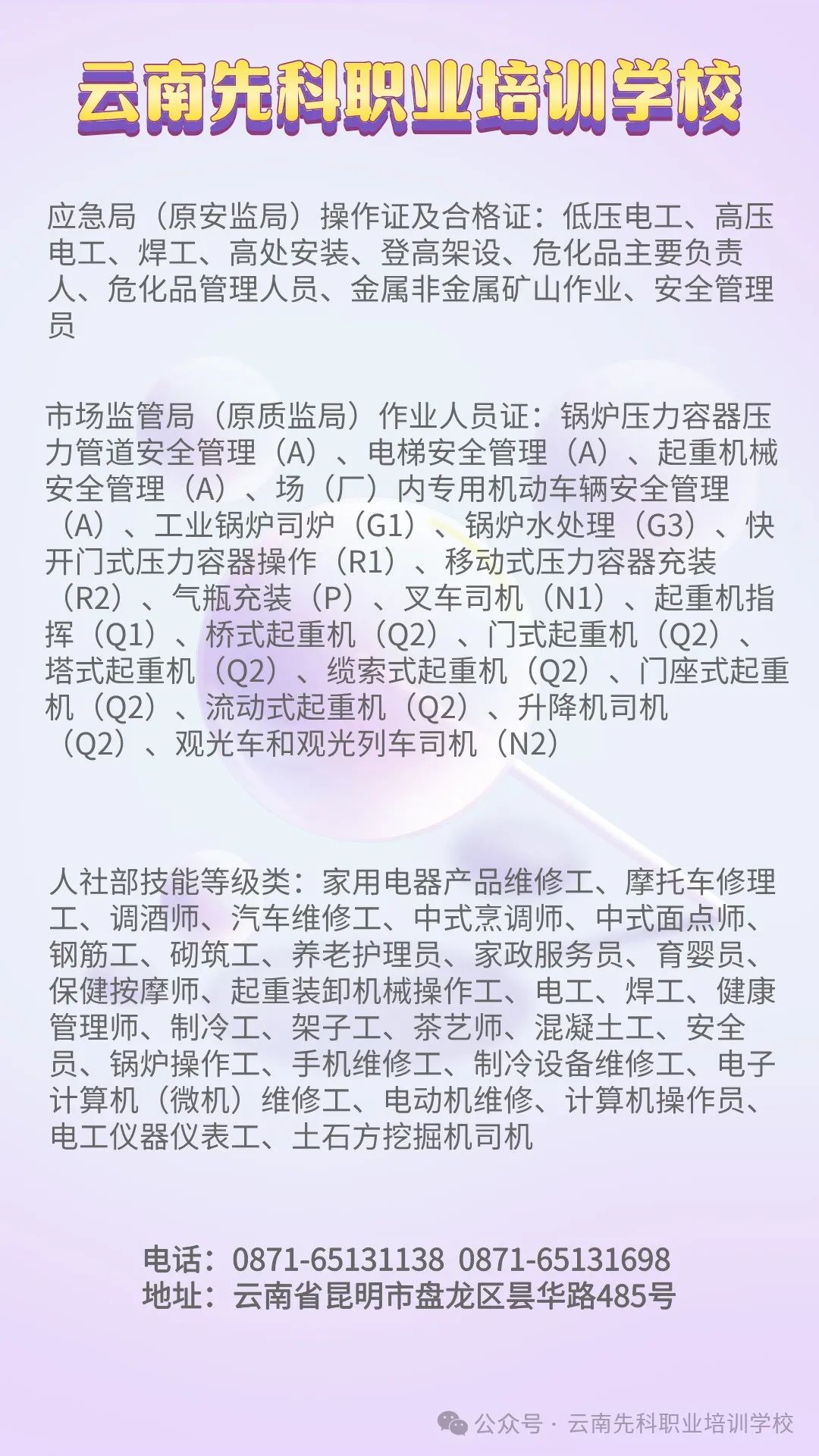

Enrollment is year-round, with classes starting every month; continuous teaching, learn at your own pace, with unified accommodation; job placement recommended!1. Registration Methods:

Register anytime, on-site registration, WeChat registration, and QQ registration are all acceptable.2. Registration Conditions:

3. Registration Hotline:

Contact Number: 0871—65131138Address: No. 485, Tanhua Road, Kunming (beside the back gate of Tanhua Temple Park)Website:www.ynxk.com.cn