The circuit board manufacturing industry is shifting from “scale-driven” to “technology-driven,” with high density, high frequency, high speed, flexibility, intelligence, and environmental sustainability as core directions.

In the manufacturing and assembly process of PCBs (Printed Circuit Boards), the cleaning stage is one of the core steps to ensure product quality and performance stability. As circuit boards undergo complex processes such as soldering, coating with conformal coatings, and surface mount technology (SMT), their surfaces are easily contaminated with solder particles, flux residues, environmental dust, and fingerprints from operators. If these contaminants are not thoroughly removed, they can directly lead to a decline in the insulation performance of the circuit board, signal transmission interference, increased risk of short circuits, and even long-term reliability issues such as electrochemical corrosion or dielectric failure.

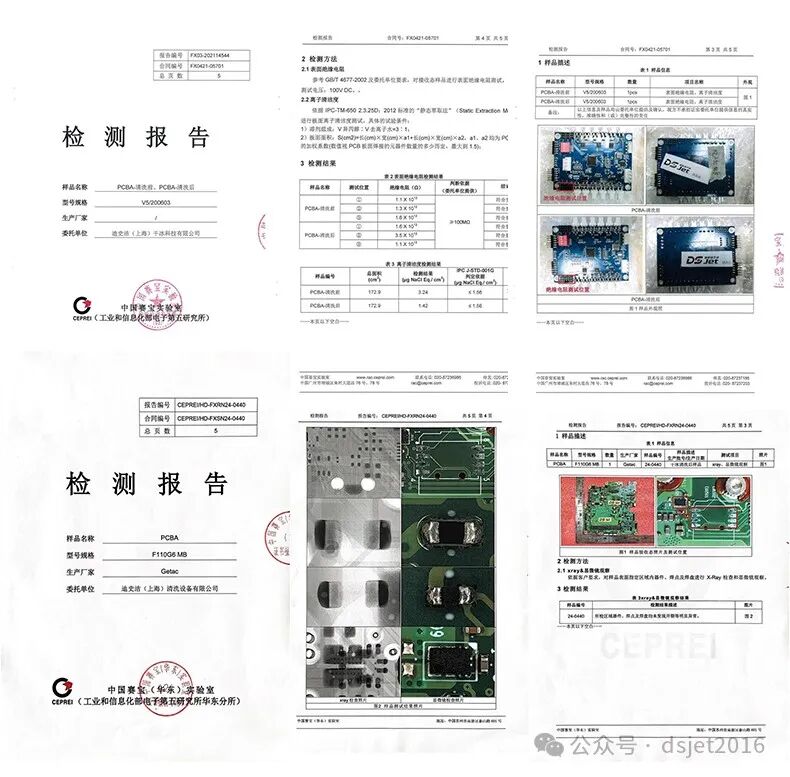

Dry ice cleaning technology is known for its efficiency, capable of removing surface contaminants from circuit boards in a very short time, significantly shortening the production cycle. Through an automated control system with preset parameters, the cleaning process can be executed precisely, avoiding the errors and fluctuations associated with manual operations, ensuring that the cleaning quality of each batch of circuit boards is highly consistent and stable. (The following is a report from the Guangwu Institute’s Saibao Laboratory)

Dry ice cleaning, also known as cold spray, utilizes dry ice particles at -78.5°C and compressed air, which are applied to the surface of objects through a spraying machine. Its principles include low-temperature freezing detachment, blowing detachment, and impact detachment, allowing contaminants to be rapidly frozen, embrittled, and removed with the airflow, achieving an efficient and residue-free cleaning effect.

Advantages of Dry Ice Cleaning

1

High cleaning efficiency: Compared to traditional solvent cleaning, the speed is increased by 30%-50%, making it especially suitable for large area or complex structure circuit boards.

2

No chemical residues: There is no need to use organic solvents (such as trichloroethylene or isopropanol), avoiding VOC emissions.

3

Low surface tension: Dry ice particles can penetrate micro-pores to remove residues.

4

Equipment compatibility: Can be integrated into SMT production lines for immediate cleaning after soldering, reducing intermediate steps.

5

Shortened cycle: No drying step is required after cleaning, allowing direct entry into the next process (such as conformal coating).

Dry ice cleaning demonstrates broad application prospects in the PCB cleaning field due to its unique advantages. With the continuous development and technological advancement of the electronic manufacturing industry, dry ice cleaning technology will play an important role in more fields, contributing to the clean production of the electronic manufacturing industry.

Get the most comprehensive information at the first timeScan the code to follow us!

Get the most comprehensive information at the first timeScan the code to follow us!