Introduction:

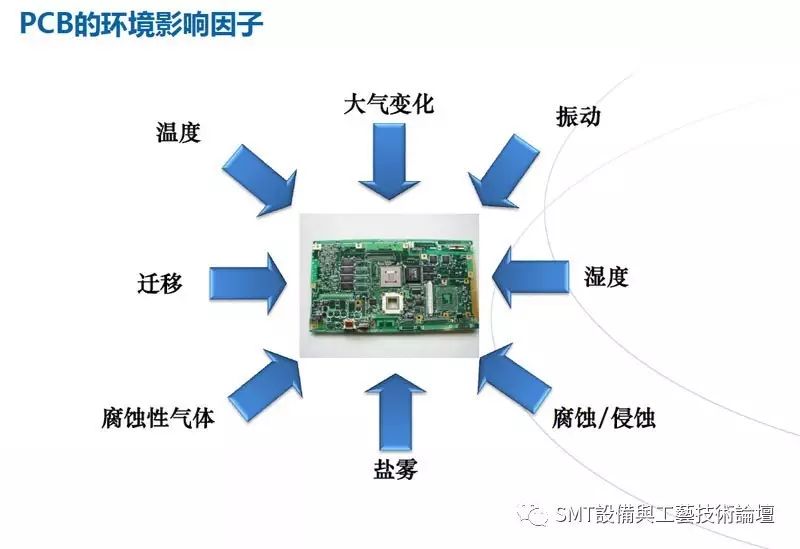

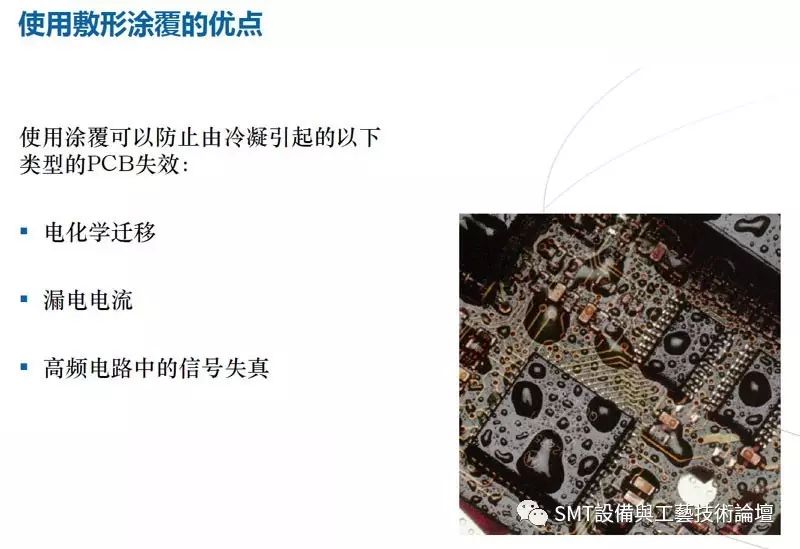

The conformal coating of PCBA (Printed Circuit Board Assembly) is an important part of the three-proof technology for military electronic equipment. Its purpose is to further enhance the resistance of the circuit board to adverse environmental effects during storage and operation, and to improve the mechanical performance of components against shock and vibration, achieving long-term protection against moisture, mold, and salt spray corrosion. It can also prevent increased leakage of printed wires and short circuits due to sudden temperature changes that create a ‘dew point’ in the air.

Additionally, for printed board assemblies operating under high voltage or low pressure, conformal coating can effectively avoid corona and creepage phenomena between wires, thereby improving system reliability. To ensure that the conformal coating achieves its intended purpose, a necessary prerequisite is that the circuit board must be clean and dry before coating. If the circuit board is not cleaned or improperly cleaned before coating, the results will be counterproductive and fail to achieve the above objectives.

▼▼

Cleaning Process Before Conformal Coating: Achieving Sustainability and Maximum Reliability

Cleaning Before Coating

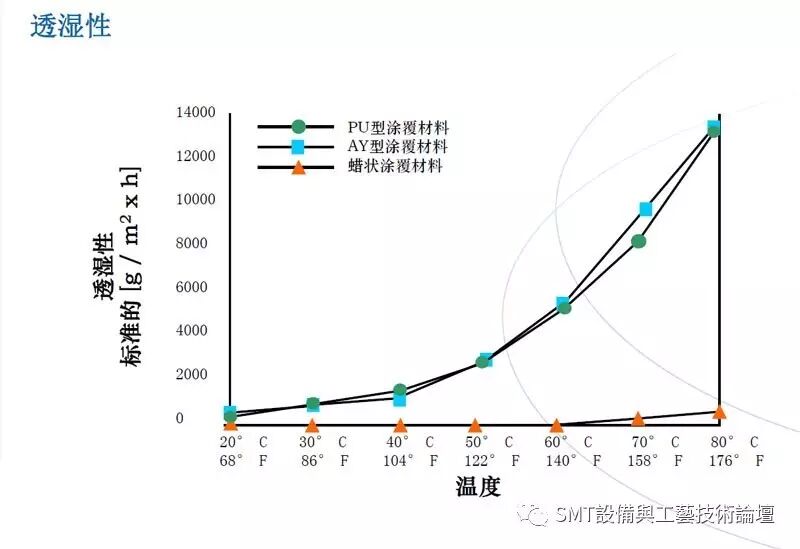

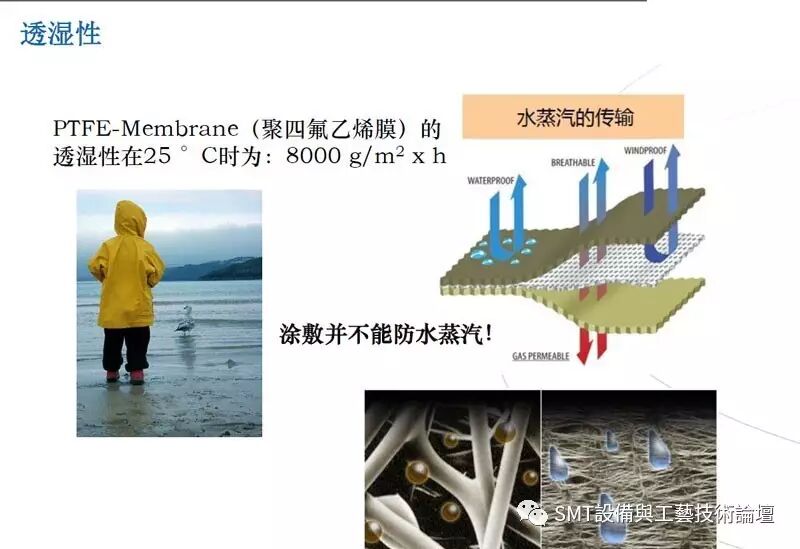

1. Contaminants under the coating layer are hygroscopic.

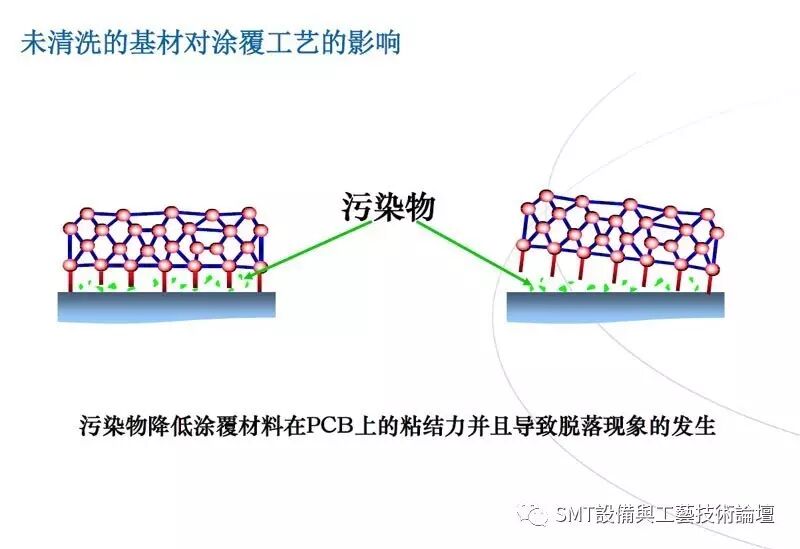

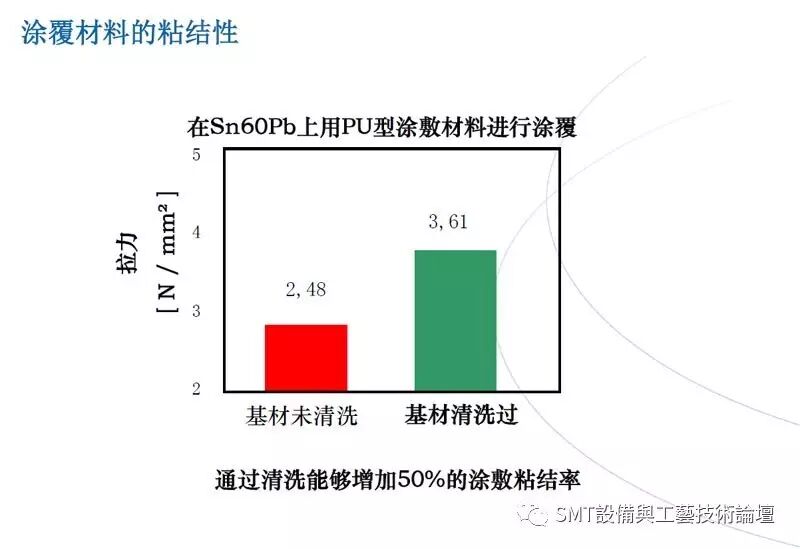

2. The adhesion of the coating material on an uncleaned PCB is poor.

3. Due to the permeability of the coating material, merely using coating is insufficient to achieve improved reliability (it may even be worse than just cleaning without coating).

4. The use of coating is intended to enhance the environmental reliability of the product.

→ Coating material suppliers also confirm: reliable coating requires prior cleaning.

Research on Cleaning Technology Before Coating

Research on Cleaning Technology Before Coating

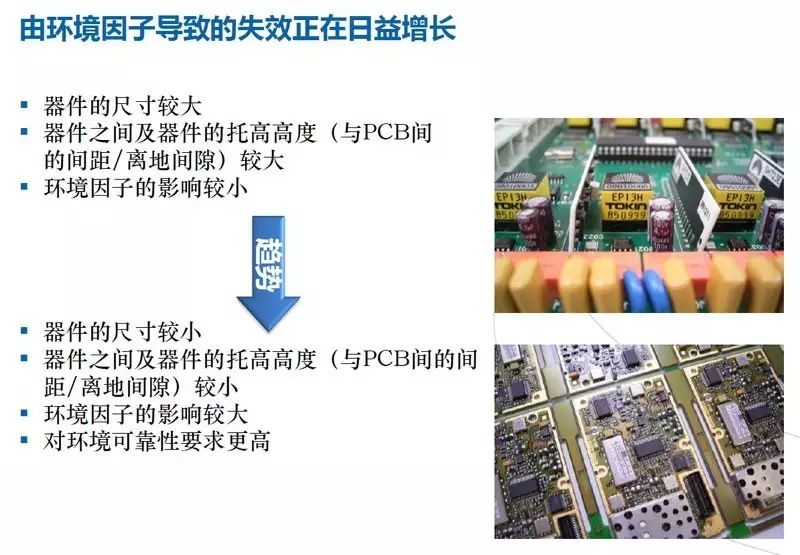

The necessity of coating

1. Higher quality demands.

2. Longer product lifespan.

3. Higher reliability requirements.

4. Miniaturization trend:

→ Smaller components, smaller gaps.

→ Lower input impedance.

5. Operation in harsh environments:

→ Temperature cycling and high humidity.

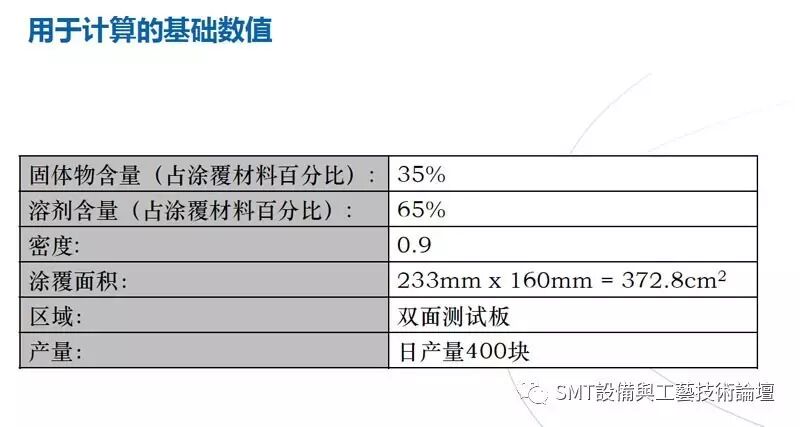

Using Coating Process: Increasing Raw Material and Solvent Consumption

1. Material consumption → cost driver.

2. Consumption of raw materials and energy.

3. Solvent emissions.

4. VOC emissions.

→ Requires additional post-processing.

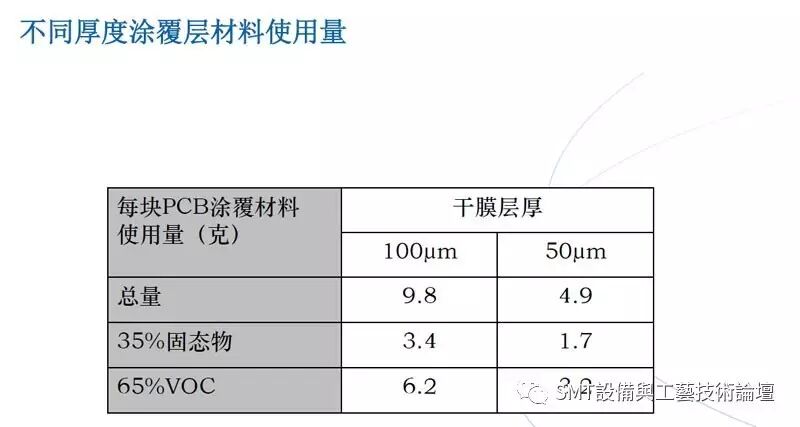

How to Use Resources More Efficiently

1. Goals:

→ Save resources.

→ Save coating materials.

→ Reduce VOC emissions.

→ Reduce production intensity.

→ Reduce energy usage, such as energy for curing.

→ Reduce footprint by using smaller curing equipment.

2. Simultaneously achieve:

→ The same or even higher coating reliability.

→ Increased profitability.

Cleaning Requirements for Coating Surfaces

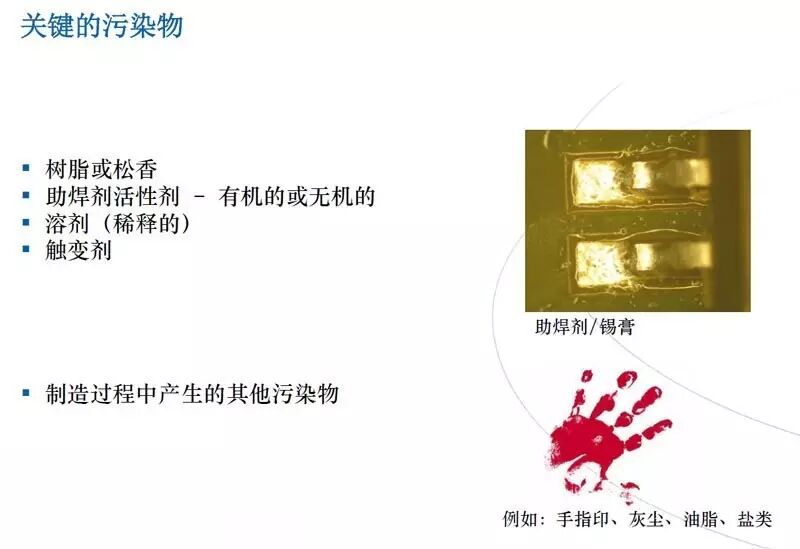

Contaminants can lead to:

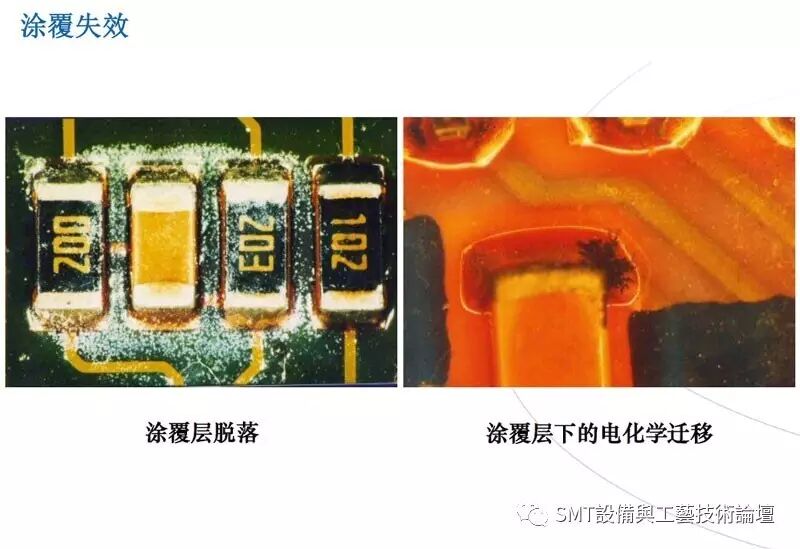

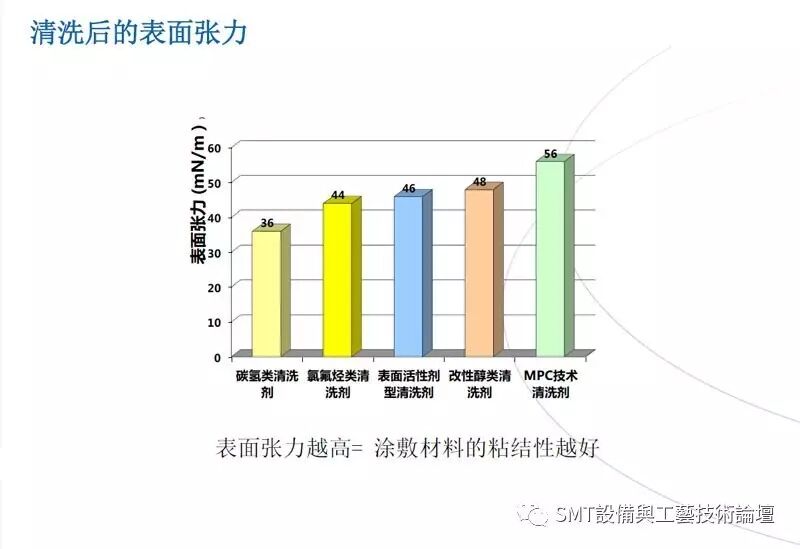

1. Poor wettability, poor adhesion, damage, and failure.

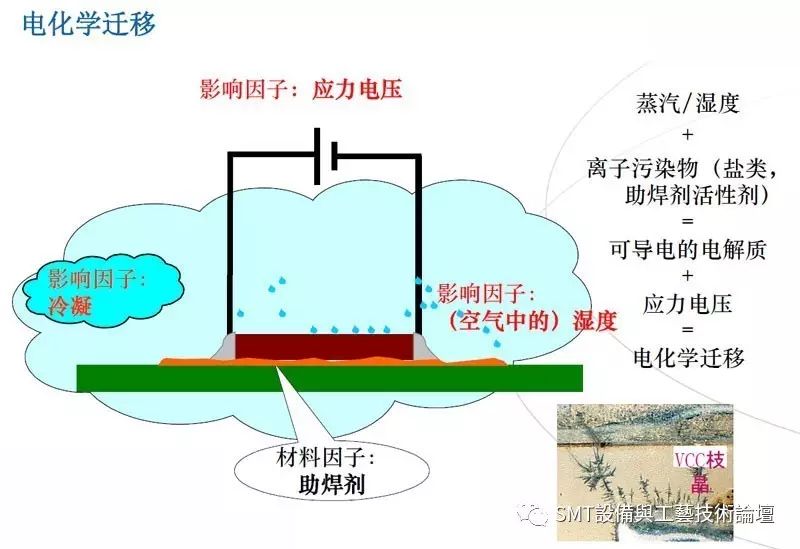

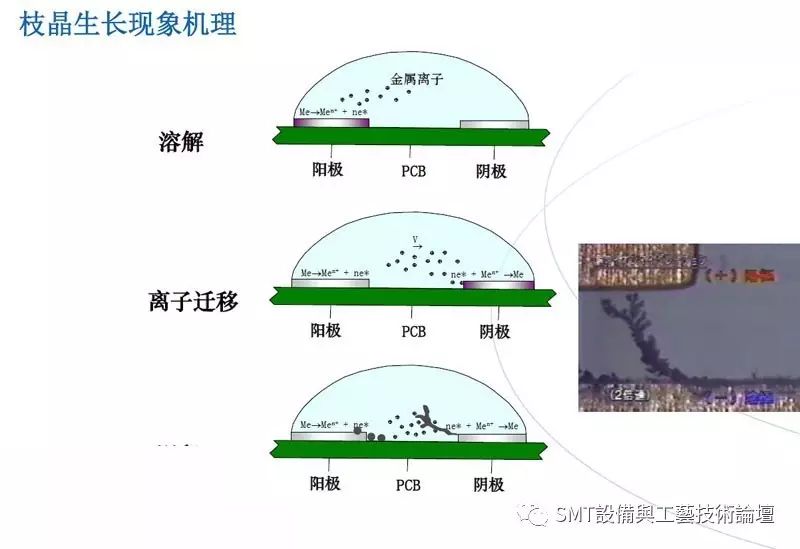

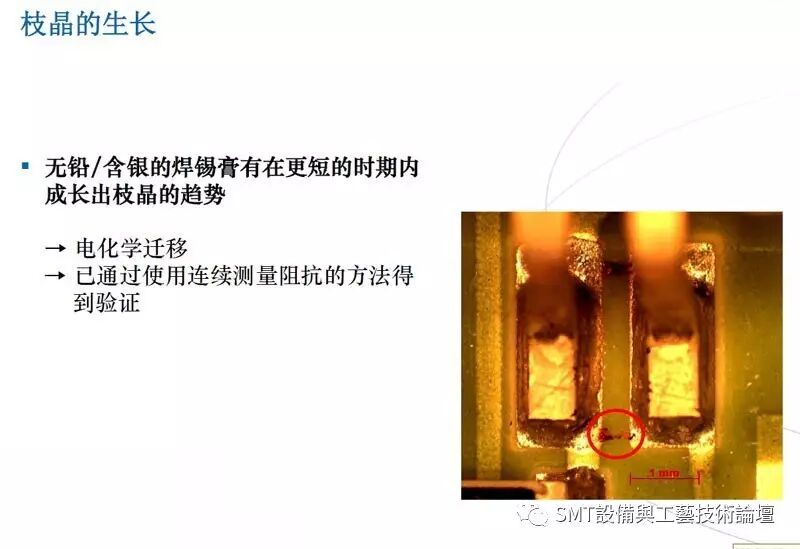

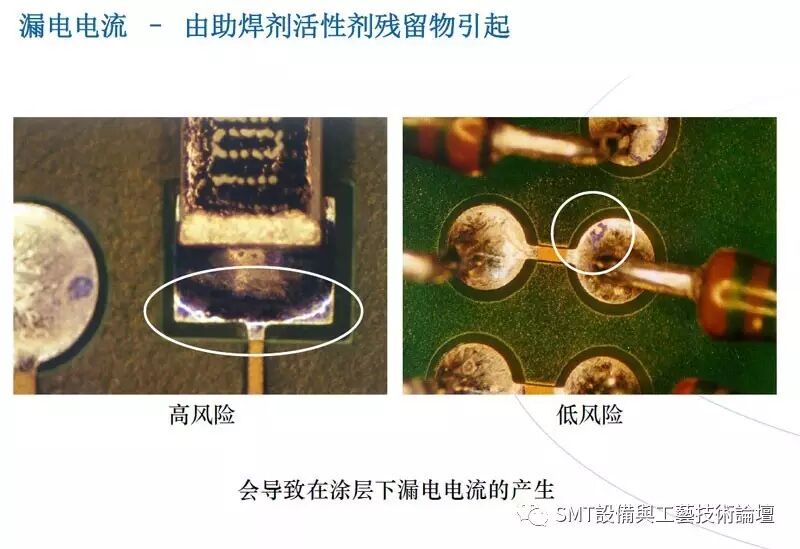

2. Hygroscopic contaminants can cause electrochemical migration.

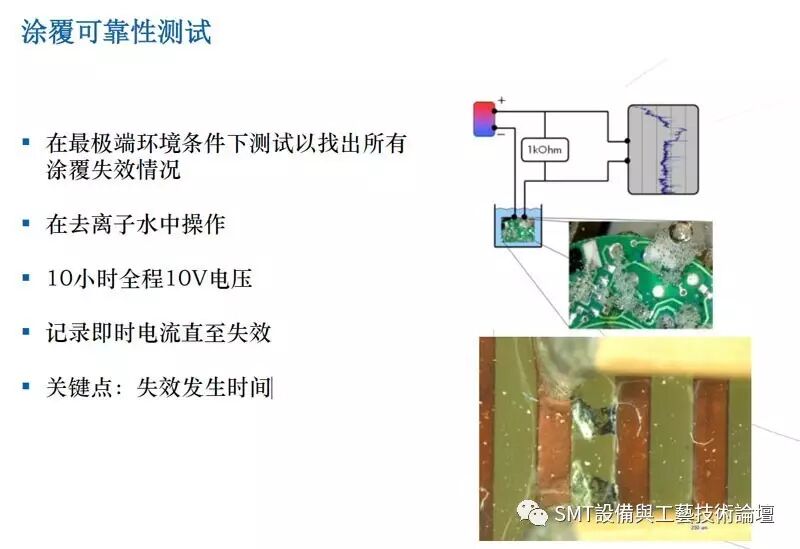

Test Boards Used in Research

1. Standard comb circuit boards.

2. Unassembled and assembled ceramic capacitors.

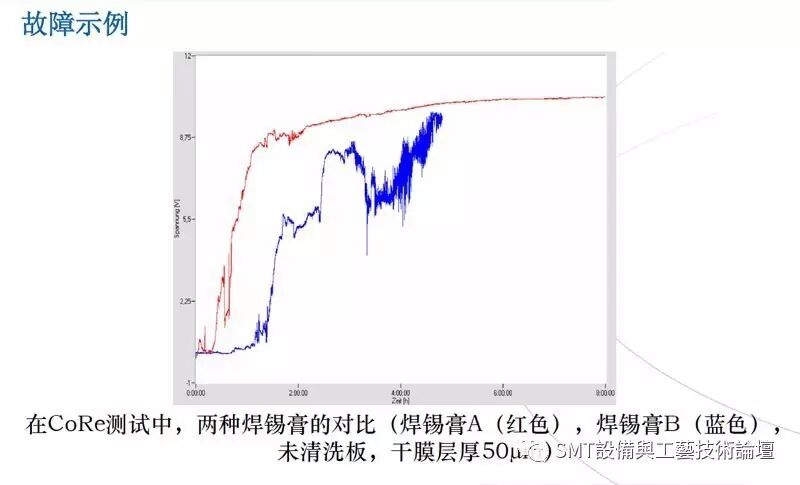

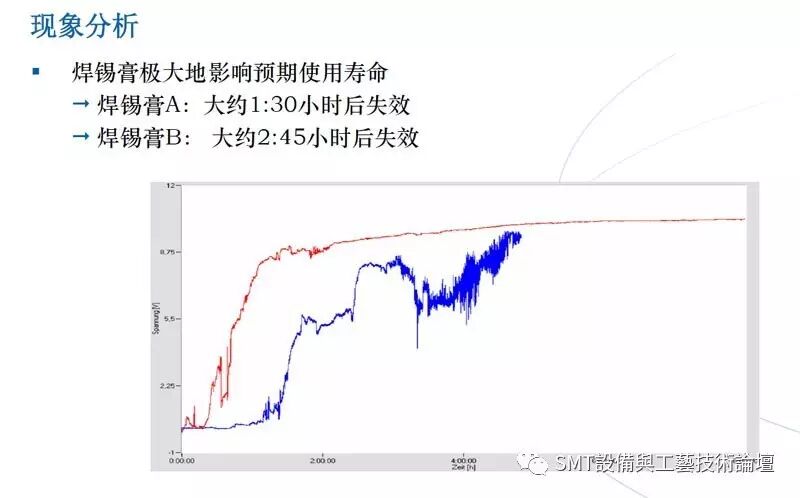

3. Two different types of solder pastes.

Cleaning Process

→ Use appropriate water-based cleaners in offline equipment.

4. Coating the assemblies according to GfKORR (German Corrosion Protection Association) standards.

Findings

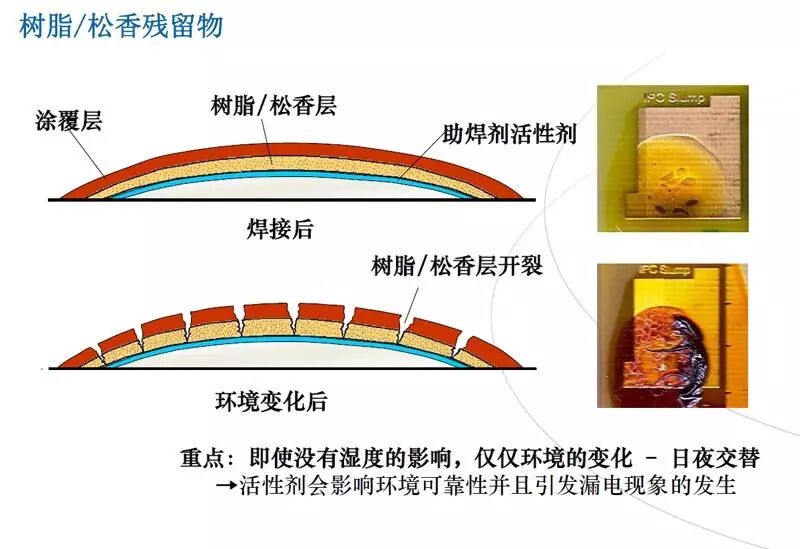

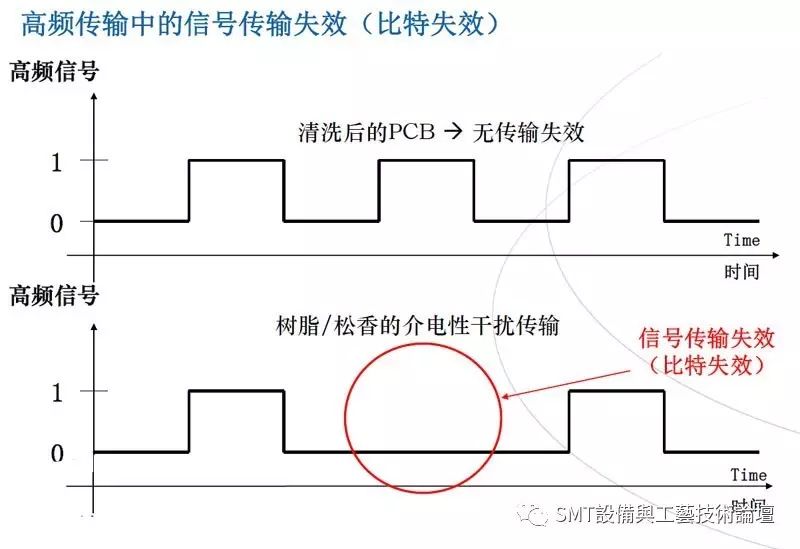

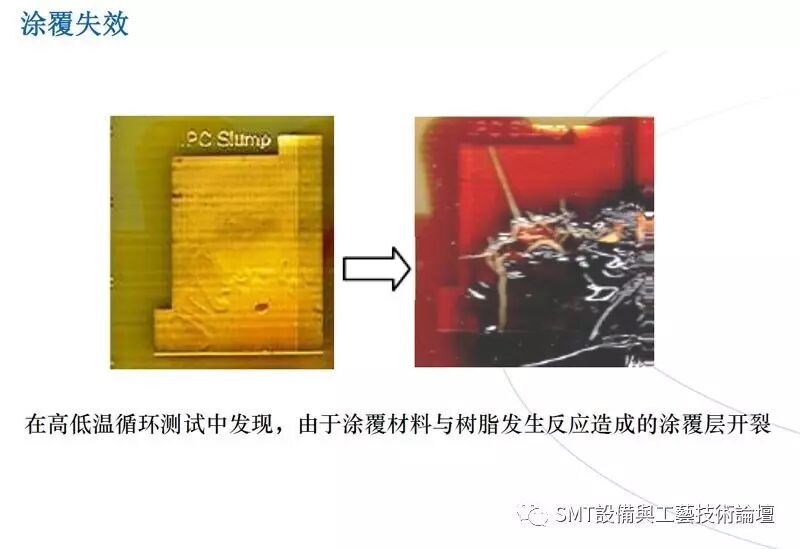

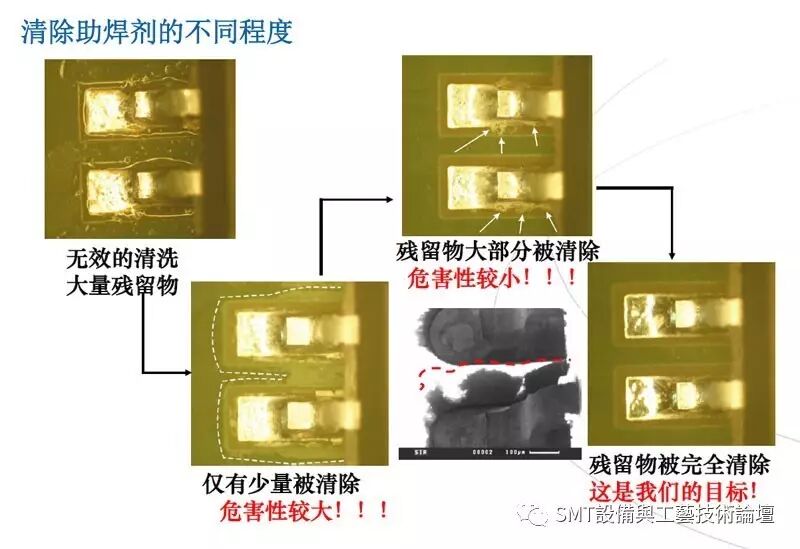

1. Resin residues are the fundamental cause of failures.

→ Reduces the adhesion and wettability of the coating layer.

→ Leads to coating adhesion failure.

2. Other residues such as flux activators:

→ Most are hygroscopic.

→ Have a negative impact on coating quality.

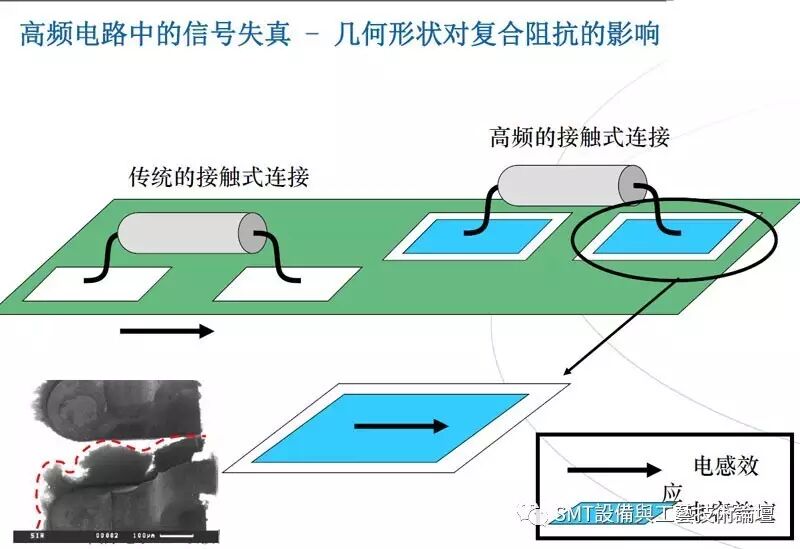

→ Cause dielectric effects.

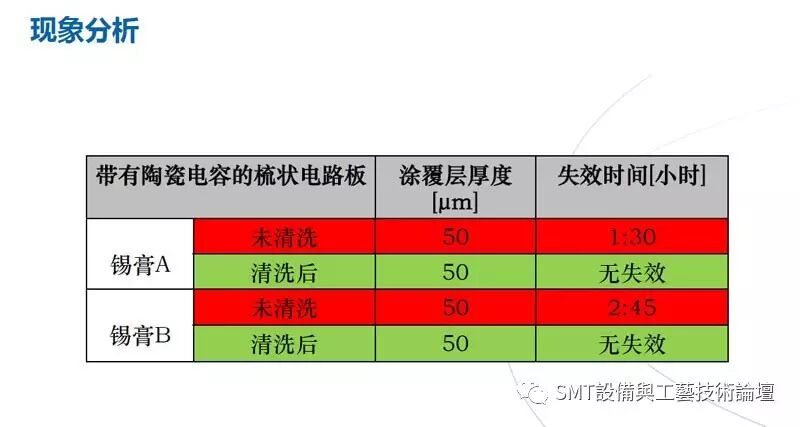

3. Failures of test boards with ceramic capacitors:

→ The shape and assembly density of the circuit board lead to mechanical stress.

→ Higher probability of failure at the edges of components.

Conclusion

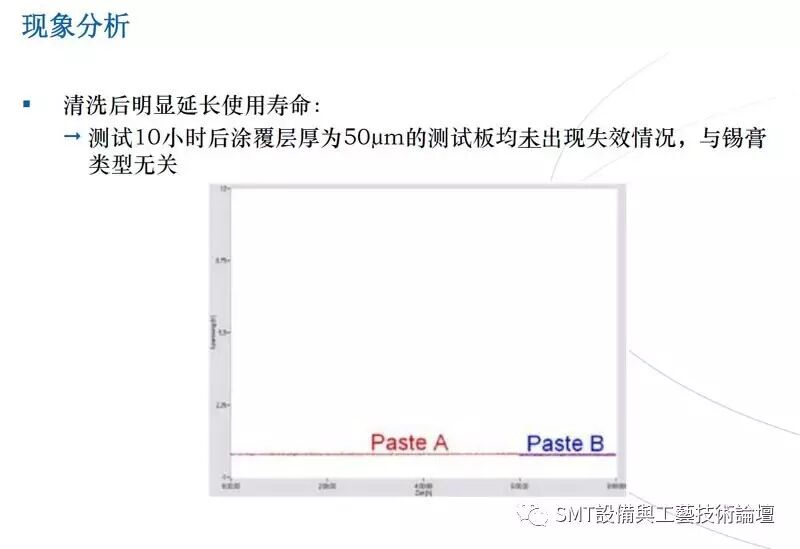

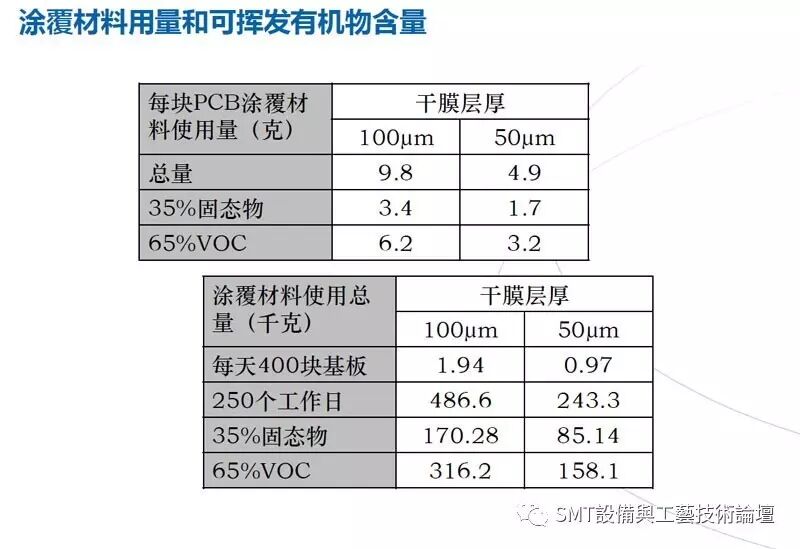

Incorporating a cleaning process before coating can achieve:

1. Significant savings in coating materials.

2. A noticeable reduction in VOC emissions.

3. Increased reliability of components after coating.

4. Sustainability of the coating process.

For more exciting past content reviews:

Essential Course for SMT Electronic Manufacturing Buyers: The Difference Between Traditional Procurement and Strategic Procurement!

💠 A Day in the Life of SMT Electronic Factory Leaders and Their Management Responsibilities❗

💠 Summary of Mainstream Smartphone Charger Manufacturers in SMT Equipment and Process Technology❗

Practical Case Analysis of Solving BGA CSP Ball Pit Defects (Head-In-Pillow)

This is the Highest Realm of “Quality Management” in SMT Electronic Manufacturing Industry!

2017 SMT Industry’s Most Popular 👍 SMT Equipment and Process Technology WeChat Public Account Collection❗

If your company has needs for senior interviews, new product introductions, press releases, industry exchanges, SMT industry opportunities, and SMT enterprise demand connections, please contact:

SMT Industry Headline Network “Electronic Manufacturing Technology Home”

E-mail : [email protected]

☞ Click the number to contact the editor for cooperation:Chinasmt188

Disclaimer:The copyright of the articles, images, audio, video files, and other materials reproduced by this public account belongs to the copyright owner. The purpose of reproduction is to convey more information, and does not represent the views of this public account or its responsibility for the authenticity. If the original author believes that their work is not suitable for public browsing or should not be used without compensation, please contact us promptly to take swift action to avoid unnecessary losses for both parties.

Original Statement:The information content is not original, originality is limited to the combination and filtering of forms!

The Most Popular SMT Industry WeChat Public Account in China

GDdz_0755SmT