When metal 3D printing meets the harsh environment of space, a heat pipe radiator that reduces weight by 50% and a shape memory alloy radiator with a 6:1 deployment ratio are two new cases that are must-sees in the field of aerospace thermal management.

Let’s take a look at what applications these are.

Real Challenges in Space Thermal ManagementHow extreme are the temperature fluctuations in space? From over 200 degrees Celsius in direct sunlight to below -100 degrees Celsius in the shadow, such drastic changes can cause any precision electronic device to fail. AM Yidao believes this is why organizations like NASA have been seeking more efficient thermal management solutions. Traditional radiators are either too heavy, not efficient enough, or prone to failure in extreme environments. On June 3, 3D Systems, a veteran 3D printing company established in 1986, announced progress in a collaborative project with Penn State University, Arizona State University, and NASA Glenn Research Center. Titanium Alloy Heat Pipe Radiator: A Breakthrough in Lightweight Technology

Titanium Alloy Heat Pipe Radiator: A Breakthrough in Lightweight Technology

First, let’s look at the results of the first project.

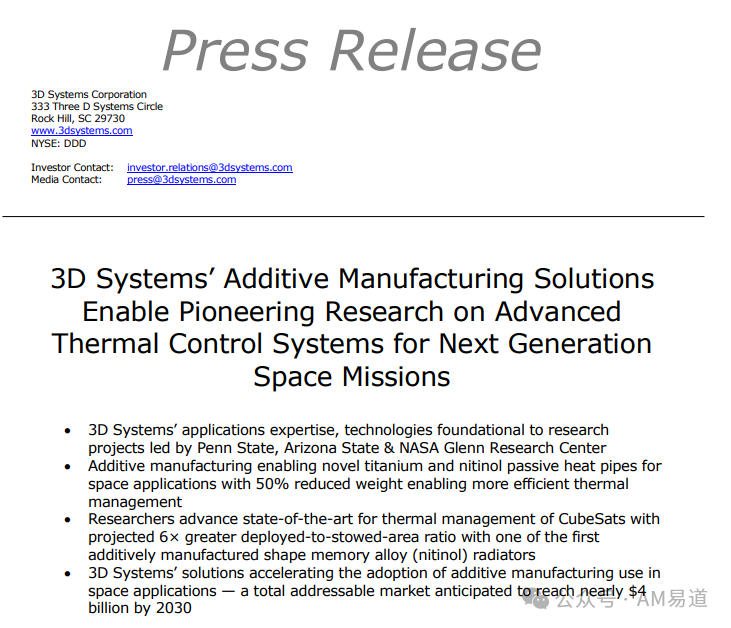

Figure 1: a. Prototype of a high-temperature titanium alloy heat radiator manufactured by additive manufacturing, embedded with a branched heat pipe network (75×125 mm and 200×260 mm panels); b. X-ray CT scan of the radiator, showing the internal porous core absorption layer for passive fluid circulation; c. Penn State University PhD student Tatiana El Dannaoui installing the radiator prototype in a thermal vacuum testing facility to simulate space environment operation; d. Thermal image of the heat pipe radiator operating in a vacuum chamber. (Image provided by Penn State University)

Figure 1 shows the prototype of the titanium alloy heat pipe radiator developed by the research team, including panels of 75×125 mm and 200×260 mm specifications.

The most attractive feature of these radiators is the embedded branched heat pipe network—clearly visible through X-ray CT scans, the internal porous core structure is key to achieving passive fluid circulation.

The image also shows Penn State PhD student Tatiana El Dannaoui installing the radiator prototype in a thermal vacuum testing facility, simulating the actual working conditions in space.

AM Yidao believes the cleverness of this design lies in utilizing the forming characteristics of metal 3D printing.

Traditional heat pipe manufacturing requires complex processes to form the internal porous core structure, while 3D printing can directly embed such complex internal networks during the printing process.

The test results are quite impressive:

This titanium-water heat pipe radiator operates normally at high temperatures of 230°C, with a weight reduction of 50% compared to traditional solutions, from over 6 kg/m² to 3 kg/m².

For aerospace applications, every kilogram of weight reduction translates to significant cost savings.

Shape Memory Alloy: An Innovative Passive Deployment Concept

The second project is even more interesting.

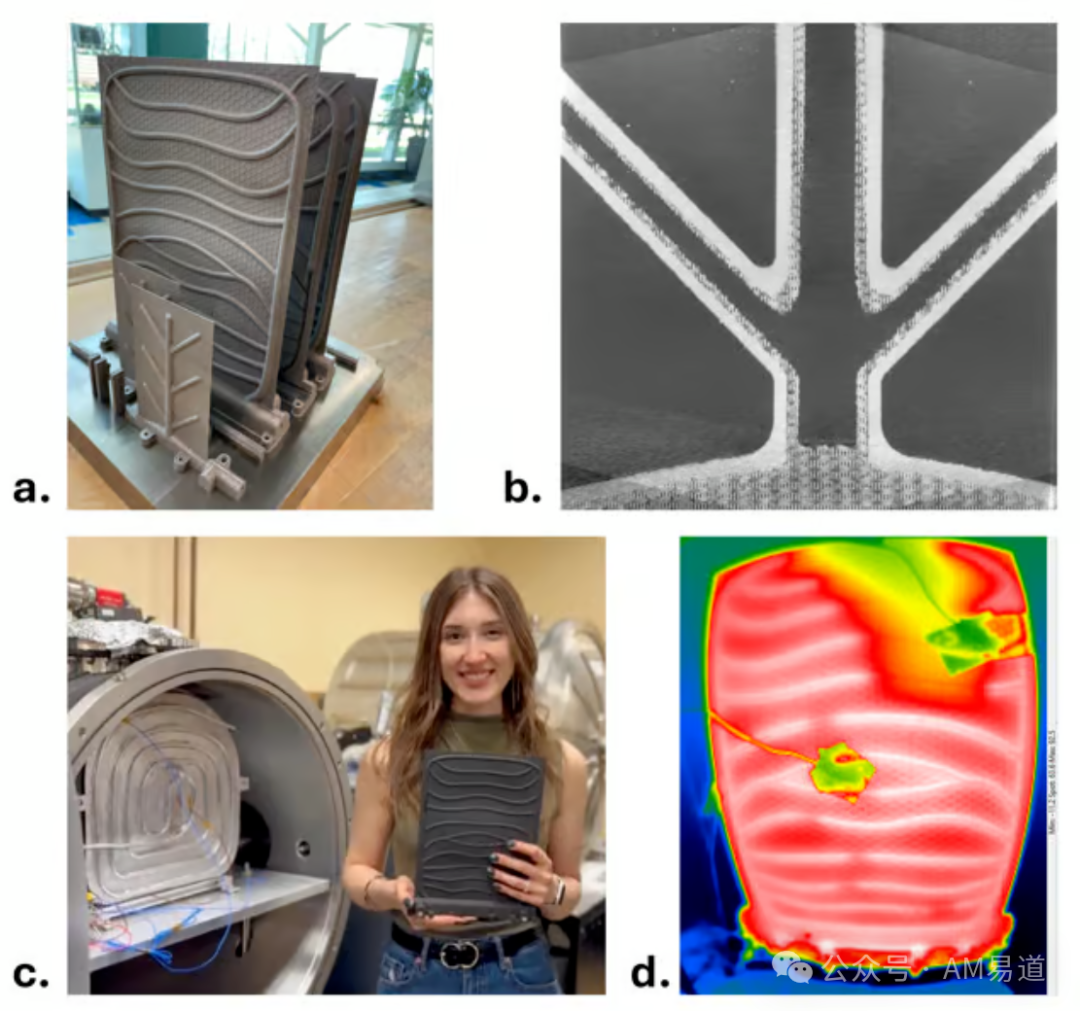

Figure 2: a. Concept diagram of an additive manufactured shape memory alloy (SMA) radiator, with radial heat pipe branches unfolding from a compact storage state. b. SMA prototype demonstrator with highly flexible corrugated pipe heat pipe arms. c. Thermal image of the SMA branched corrugated pipe heat pipe, showing its near isothermal operation. (Image provided by Penn State University)

Figure 2 shows the concept diagram and prototype demonstrator of an expandable radiator made from nickel-titanium shape memory alloy (nitinol).From the image, we can see the design concept of this radiator unfolding radially from a compact storage state, along with the highly flexible corrugated pipe heat pipe arm prototype.The thermal imaging shows that the SMA branched corrugated pipe heat pipe operates almost isothermally, demonstrating its excellent thermal conductivity.It can be imagined that the application scenario is when the radiator is stored in a compact form during satellite launch, and automatically unfolds into a radial structure after entering orbit through internal fluid heating.This passive deployment mechanism eliminates the need for motors or other traditional drive devices, making this simple and reliable design particularly valuable in the almost impossible maintenance environment of space.Project data shows that this SMA radiator has a deployment-to-storage area ratio of 12:1, a sixfold improvement over the current state-of-the-art 2:1, while reducing weight by 70%, from 19 kg/m² to less than 6 kg/m².Technical Accumulation of Established Enterprises

According to 3D Systems’ own disclosures, over the past decade, they have manufactured more than 2,000 titanium or aluminum alloy structural components for space flight, as well as over 200 critical passive RF flight components.

Currently, more than 15 satellites are operating in orbit with flight hardware manufactured by them.

Penn State Associate Professor Alex Rattner mentioned that the long-term R&D collaboration with 3D Systems has allowed them to explore advanced design strategies and push the boundaries of existing technology, thanks to their combined expertise in aerospace engineering and additive manufacturing.

The low-oxygen environment 3D printing platform, combined with 3DXpert software capabilities, enables the team to manufacture new components with significantly enhanced performance using special materials.

Market Prospects and Technological TrendsAccording to Research and Markets, the additive manufacturing market in the aerospace sector is expected to grow from $1.2 billion in 2023 to $3.8 billion by 2030.This growth reflects the gradual transition of 3D printing technology in aerospace applications from concept validation to practical application.Returning to In-Depth Technical ConsiderationsFrom a technical perspective, these two projects demonstrate the unique value of metal 3D printing in functional integration.Under traditional manufacturing methods, heat pipes and radiators are usually manufactured separately and then assembled, while 3D printing can achieve integrated forming.This not only reduces assembly steps but also eliminates contact thermal resistance, improving overall thermal conductivity efficiency.The combination of shape memory alloy and radiator structure in 3D printing concepts can inspire many new ideas.Although these two projects target aerospace applications, their technical principles and design ideas are also valuable references for other industries.High-performance computing, automotive electronics, data centers, and other fields all face thermal management challenges, with a broad demand for lightweight and efficient thermal management solutions.

Source: AM Yidao 3D Systems Official Press Release

Disclaimer: Cheqian Information adheres to the principle of respecting originality and serving the industry together. This public account will indicate the source for reprints based on sharing purposes. The copyright of reprinted articles belongs to the original author or original public account. If there is any infringement, please contact 021-31656996.