The global industrial-grade3Dprinter market is dominated by major players from Europe and the United States, while Chinese companies are accelerating their catch-up efforts. Below is a list of core companies categorized by technology route along with key product parameters:

1. Large Metal3DPrinter Companies

1. Laser Powder Bed Fusion (LPBF)

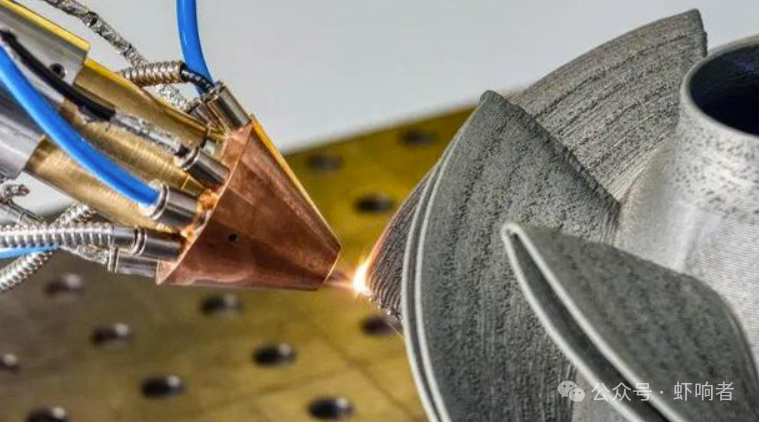

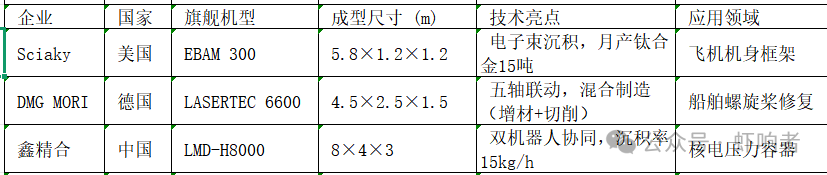

2. Directed Energy Deposition (DED)

2. Large Polymer3DPrinter Companies

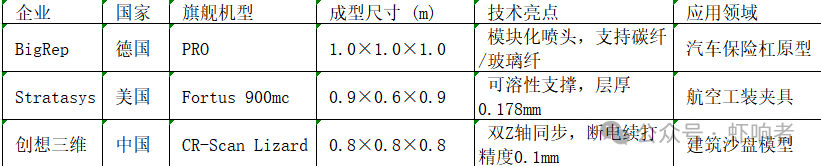

1. Thermoplastic Material Extrusion

2. Photopolymerization (SLA/DLP)

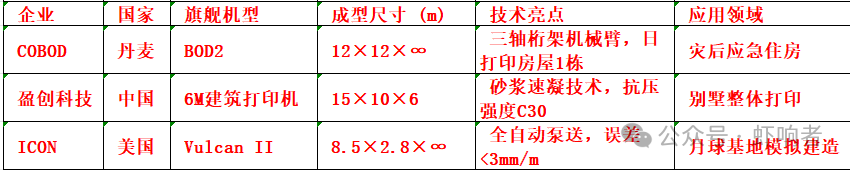

3. Concrete/Construction-Specific Printers

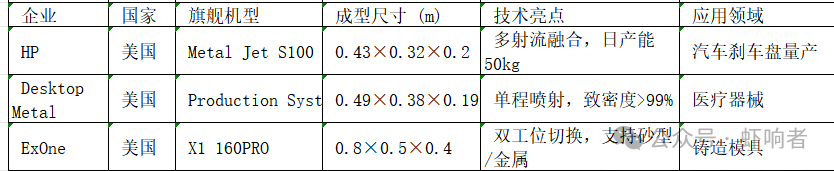

4. Binder Jetting Technology Companies

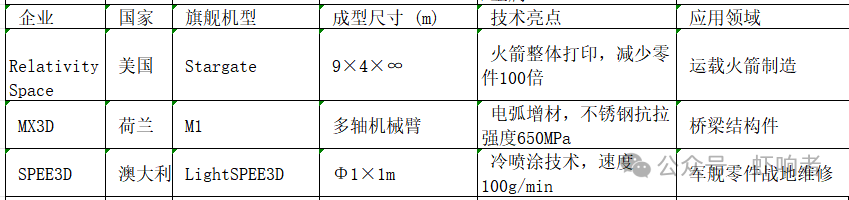

5. Frontier Technology Explorers

Company Layout Analysis

Title 2023Global Large3DPrinter Market Share

“European and American Companies”: 68

“Chinese Companies”: 25

“Other Regions”: 7

Competitive Landscape of Technology Routes:

1. Metal Printing: The German duo (EOS/SLM) monopolizes the high-end market, while Chinese and American companies focus on large-scale deposition.

2. Construction Printing: Denmark’sCOBODleads the way, with China’s Yingchuang having the strongest engineering capabilities.

3. Multi-Material Printing: The United StatesHP/Desktop Metalis driving a revolution in binder jetting mass production.

Key Indicators for Purchasing Decisions

| Parameter | Industrial Grade Threshold | Civil Grade Threshold |

| Positioning Accuracy | ±50μm | ±200μm |

| Maximum Printing Speed | 300cm³/h(Metal) | 1000cm³/h(Plastic)

| Temperature Control Stability | ±2℃(全仓) | ±5℃ |

| Continuous Working Hours | >720Hours | >200Hours

| Software Ecosystem | SupportsSTEP/Parasolid | STLBasic Slicing |

Chinese Strengths and Breakthrough Directions

1. Platinum Technology: Achieving import substitution in aerospace and military industries, reducing titanium alloy printing costs to 60% of that in Europe and the United States.

2. Huashu High-Tech: Breaking through EOS patent barriers with an open-source strategy, reducing equipment prices by 40%.

3. Xinjinghe: Leading the world in giant component printing technology (>8m), serving the repair of the Three Gorges hydropower turbine.

> Warning: European and American restrictions on exports to China include metal printers with dimensions ≥1.5m. Domestic companies need to overcome high-precision long-stroke guide rails (error<0.01mm/m) and high-power lasers (>8kW) bottleneck technologies.

Industry Trend Predictions

1. Multi-Technology Integration:

– The penetration rate of hybrid manufacturing (printing + cutting) will increase from15%to40% by 2030.

2. Intelligent Upgrades:

– AIreal-time defect detection will become standard for high-end models (e.g., SiemensAdditive Quality).

3. Green Manufacturing:

– The recycling rate of metal powder will increase from60%to>95% (EU mandatory standard by 2025).

The essence of competition in large 3D printers is the integration of materials – equipment – software ecosystems. Chinese companies need to accelerate their layout in open material systems (e.g., supporting domestic high-temperature alloys) and cloud control platforms.

************(End)************May the people we meet, the things we experience, and the sights we see become better because of our existence.May our great motherland prosper forever!May our lovely lives continue to be beautiful!