As a leading enterprise in China’s 3D printing field, Shanghai Prusa 3D Technology Co., Ltd. (hereinafter referred to as “Prusa”) has been deeply engaged in the digital dentistry field since its establishment in 2005, with the core concept of “solving personalized problems through industrial means.” By collaborating with the German chemical giant BASF to develop high-performance photopolymer resin materials, Prusa has created solutions covering 70% of the dental material product line, facilitating mass production for dental applications such as invisible orthodontics and implant guides. Its 24-hour unmanned “dark factory” can achieve an annual output of 36 million customized dental molds, making it the “double champion” in the global dental 3D printing market.

The success in dentistry is a stepping stone for Prusa towards the micro-nano era. Leveraging the intelligent manufacturing experience accumulated in the dental field, Prusa is now focusing on higher precision micro-nano 3D printing technology. By leading the key research and development program of the Ministry of Science and Technology, “Micro-Nano Structure Additive Manufacturing Processes and Equipment,” Prusa has overcome the challenges of micron-level precision manufacturing, pushing the 3D printing accuracy to 2 microns and achieving printing speeds more than a hundred times faster than traditional processes.

Core Advantages of Prusa’s Micro-Nano 3D Printing

Prusa’s technological competitiveness stems from its independently developed Sub-Pixel Micro-Scanning Technology (SMS), which achieves a “dual breakthrough in precision and speed”:

Seamless full-area exposure: Traditional 3D printing requires multiple stitching exposures, which can lead to errors. In contrast, SMS technology uses area-array exposure to complete the formation of complex structures in one go, completely eliminating stitching errors and improving efficiency nearly a hundredfold.

Ultra-high speed and high precision in parallel: The printing speed can reach tens of thousands of times that of two-photon technology, while maintaining a stable precision of 2 microns. It supports various materials such as resin, ceramics (like alumina and zirconia), and metals (like TC4 alloy and copper), meeting the complex demands of different fields.

Complete domestic industrial chain: Core technologies and equipment are fully controllable, with 67 domestic and international patents (including 10 international patents), and a localization rate of core components reaching 100%.

Industrial Application Map of Micro-Nano 3D Printing

Prusa’s micro-nano technology has penetrated into high-precision fields such as medical, consumer electronics, and aerospace, forming a diversified application ecosystem:

1. Medical Field: A Revolution from “Minimally Invasive” to “Precision”

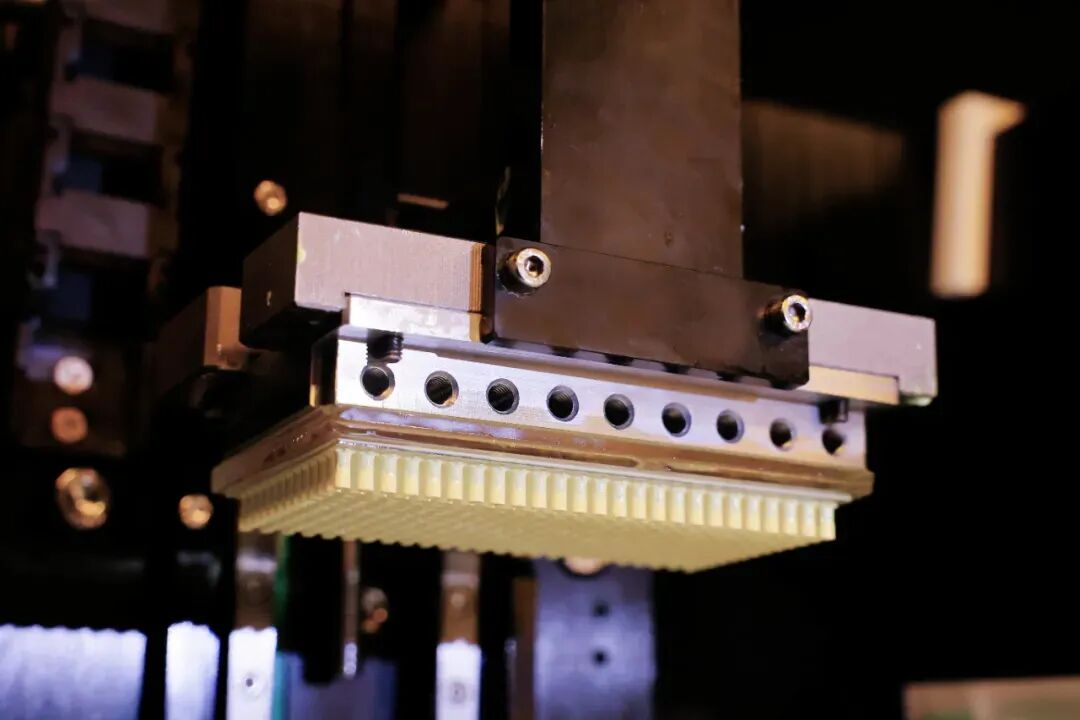

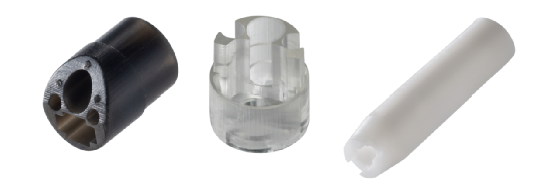

End of endoscope: Breakthrough in constructing thin-walled channels with a depth-to-diameter ratio of 20 mm, ensuring an ultra-thin wall thickness precision of 80 microns while forming a complex internal network system with multiple dimensions. Using alumina, zirconia, and photosensitive resin, it has good biocompatibility. Supports rapid R&D iteration, replacing traditional machining.

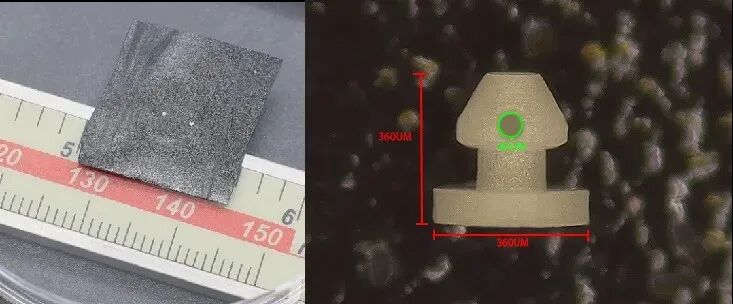

Glaucoma drainage stent: Overall size less than 400 microns, pore diameter 60-80 microns, high strength and biocompatibility make it the preferred implant for minimally invasive ophthalmic surgery.

Hierarchical vascularized organ-on-a-chip: Developed in collaboration with Shanghai Jiao Tong University, this organ-like chip can simulate the microenvironment of human organs, promoting targeted drug development, with results published in international authoritative journals.

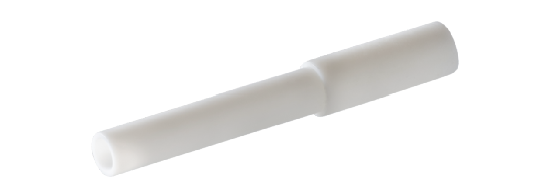

Microwave ablation tube: Wall thickness of 100 microns, made of ceramic materials, with good biocompatibility, high strength, and breakdown resistance.

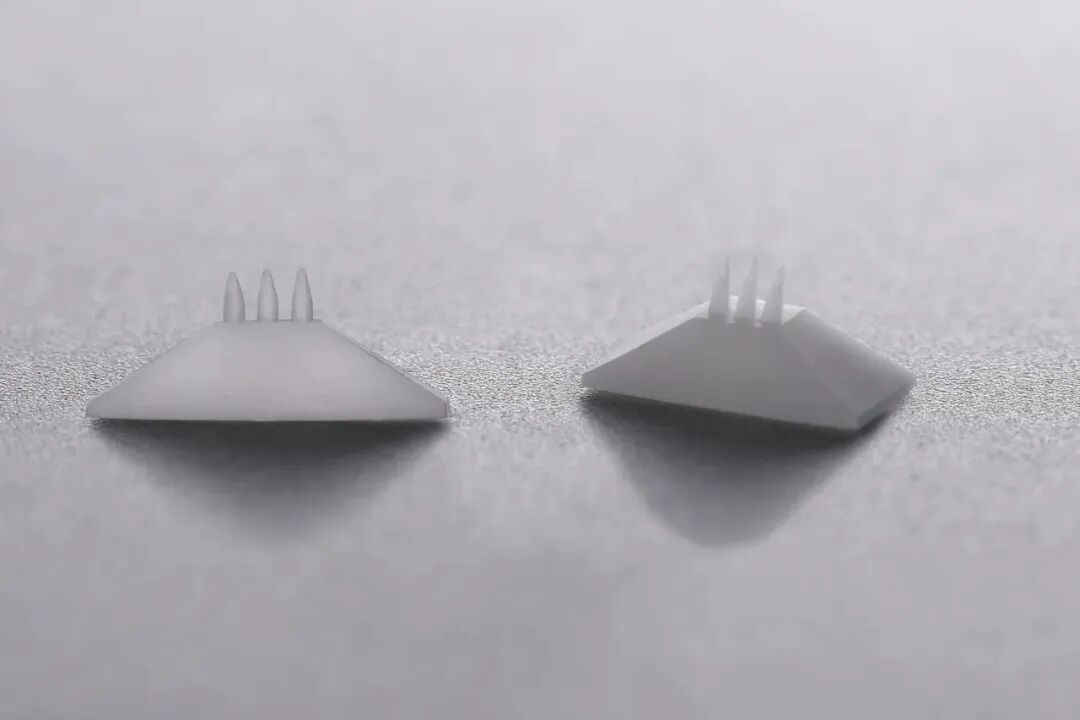

Ceramic hollow microneedles: Needle tip only 3 microns, supports painless transdermal drug delivery, applicable in medical aesthetics (hyaluronic acid, collagen injections) and drug delivery (insulin, vaccines), avoiding the risk of needle breakage associated with traditional silicon-based microneedles.

2. Consumer Electronics: Empowering 6G Communication and Smart Hardware

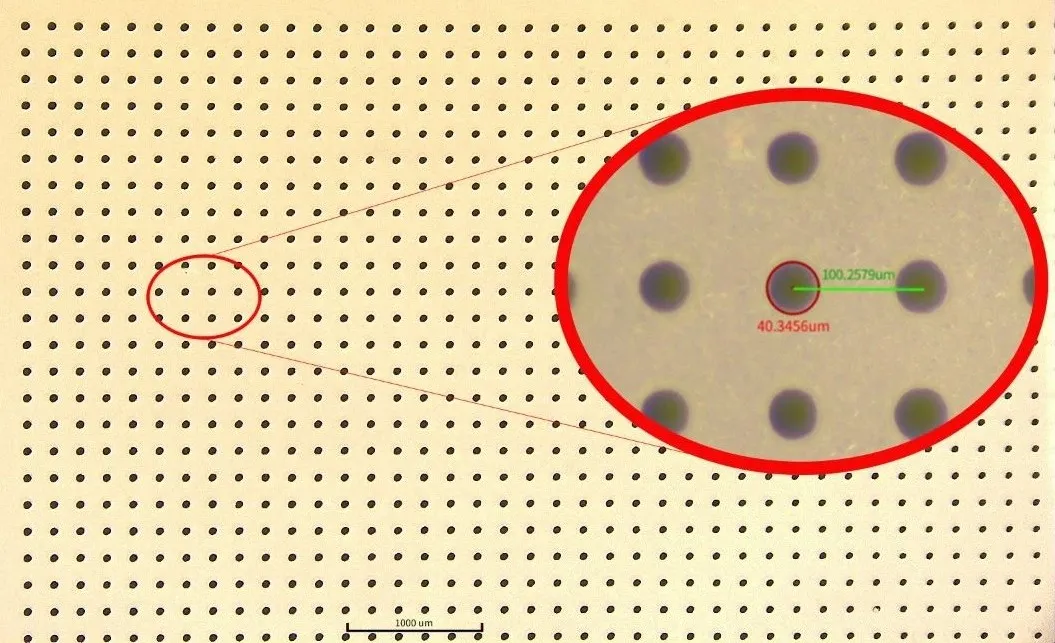

Micro-display devices and brain-machine interfaces: 10,000 micropores with a diameter of 30 microns can be printed on a 1 square centimeter ceramic plate, providing a precise carrier for brain-machine interface electrode arrays.

△ Micro-pore array ceramic substrate

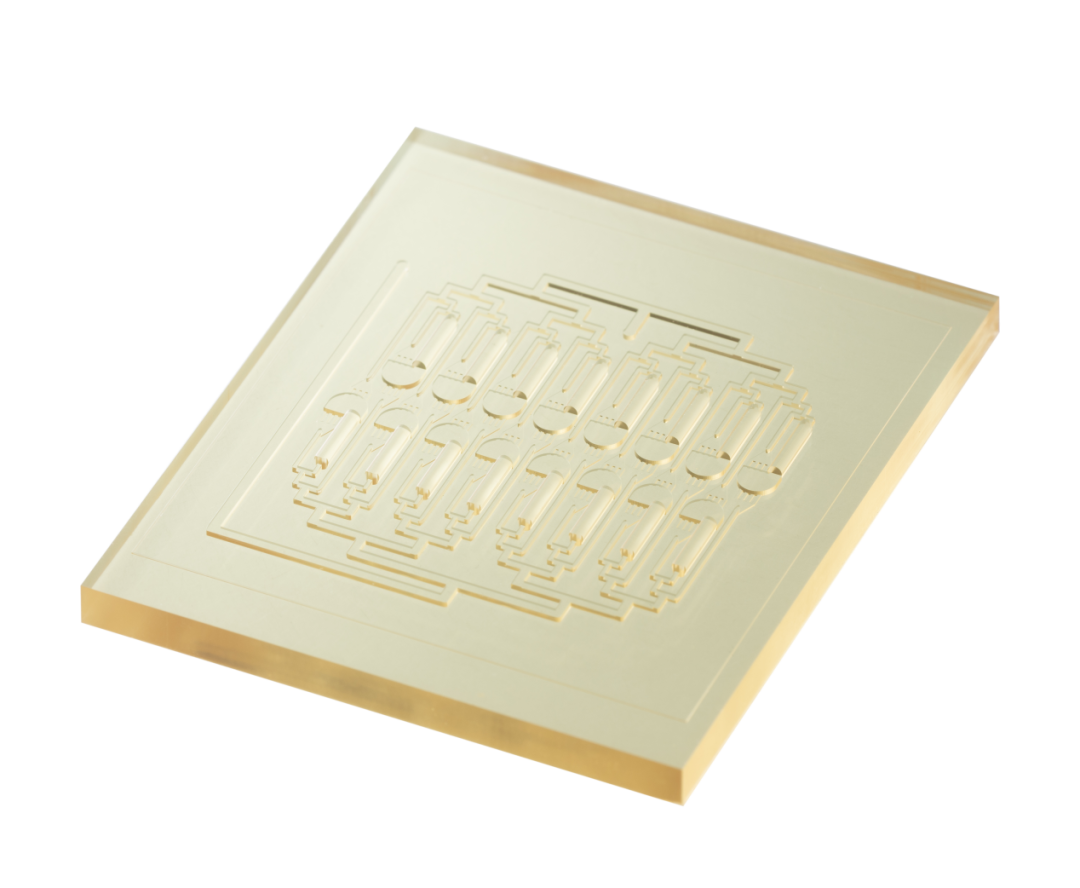

Microfluidic chips: Used in biological detection and pharmaceutical R&D, achieving precise control of micro-quantities of liquids, with detection efficiency improved by more than three times.

Future Outlook: Domestic Technology Leading Globally

Prusa’s success confirms the foresight of the “limited personalization” strategy—solving high-precision customization challenges through industrial means, meeting niche market demands while achieving scale cost reduction. In the future, as micro-nano technology deeply penetrates fields such as brain-machine interfaces and targeted medicine, Prusa is expected to become a “rule maker” in global precision manufacturing.

As Prusa’s chairman, Hou Feng, stated: “Technological independence and control is the only passport to participate in international competition.” In this tough battle for domestic substitution, Prusa, armed with micro-nano technology, is paving a path for China’s high-end manufacturing industry from following to leading.