1

Introduction

A few days ago, a friend asked me for a quick way to configure multiple motors and cylinders on a touchscreen in their project, as configuring each object one by one was cumbersome.

In fact, it is possible to use the panel function in the touchscreen. By configuring such a panel, the variables used in the panel can be dynamic variables. When calling the panel, you can associate these dynamic variables with the corresponding variables.

2

Configuring the Panel

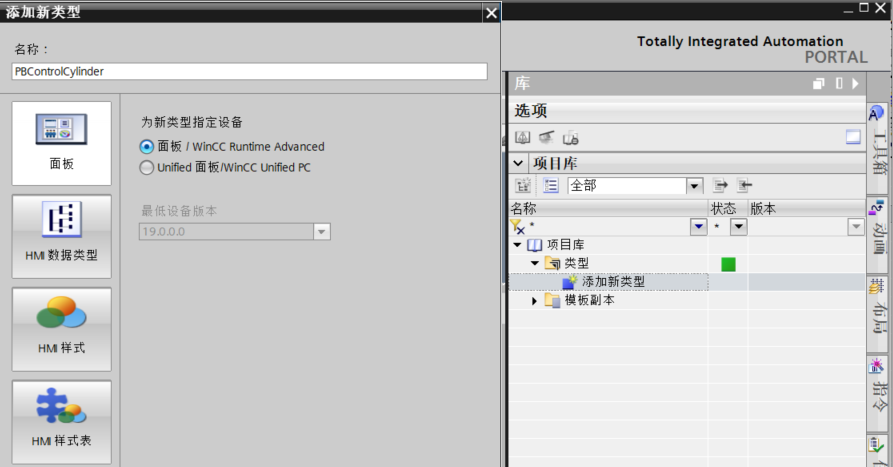

To add a panel: Select the “Library” option on the right side of the project tree, expand the project library, double-click to add a new type in the type options, select “Panel” in the pop-up add new type options, specify the device type as “Panel/WINCC Runtime Advance”, and name the panel as shown in the figure below. After naming, click the OK button to enter the panel configuration interface.

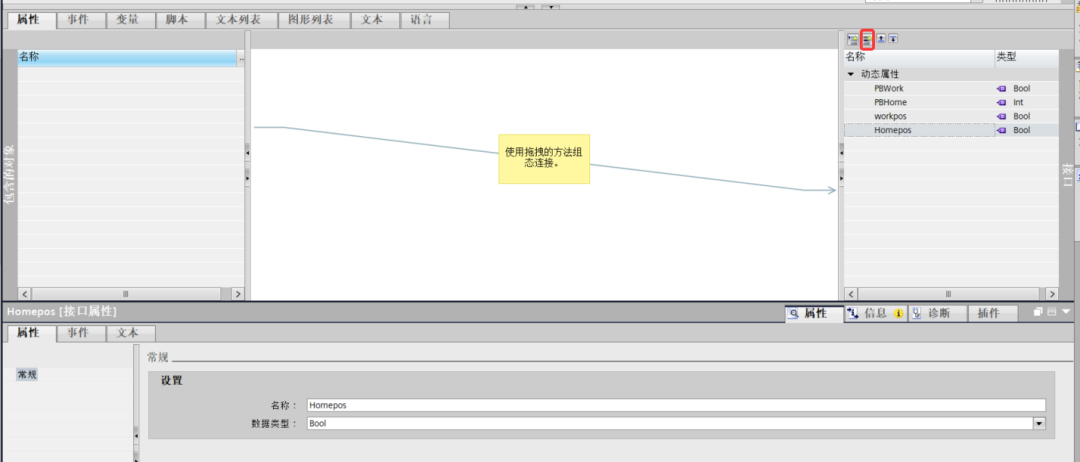

Creating Dynamic Variables: In the dynamic properties interface, create the four variables needed for manual control of the cylinder. Click the “Add Property to Selected Category” button to add variables, and rename and select the corresponding data type for each variable as required, as shown in the figure below:

Configuring the Cylinder Control Panel: In the panel, configure a screen object for cylinder control. Here, you need to select two buttons configured for the control and return states, and two display frames to show the working position and original position sensing. Use the toolbox to select objects and elements to complete the configuration.

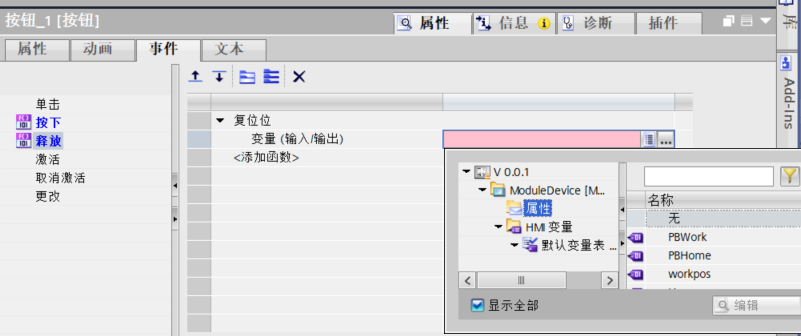

Configuring Buttons: In the button’s event properties, configure the press and release events, associating functions with the set and reset positions in the edit position function, and select variables from the dynamic properties, as shown in the figure below:

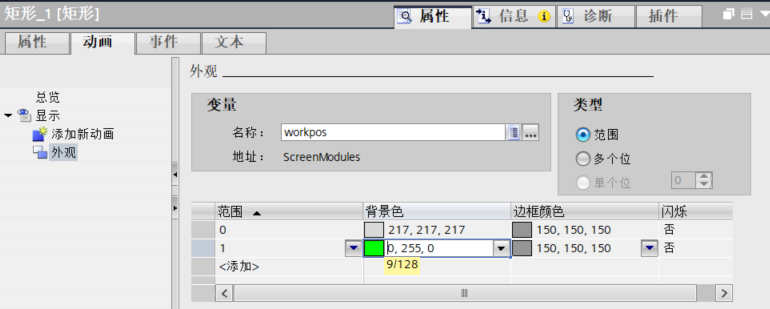

Limit Display Configuration: Double-click the rectangular box representing the fiber, and in its animation properties, associate the appearance animation properties. Configure one color when the variable value is 0 and another color when the variable value is 1, selecting the variable from the dynamic properties, as shown in the figure below:

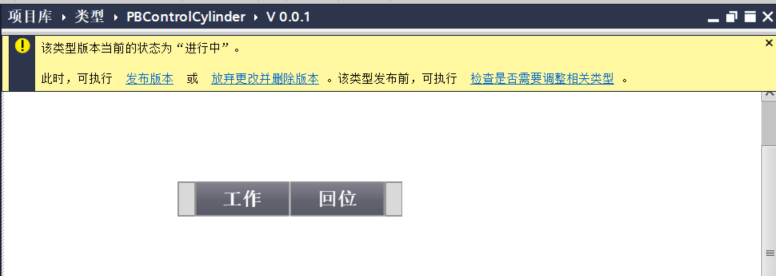

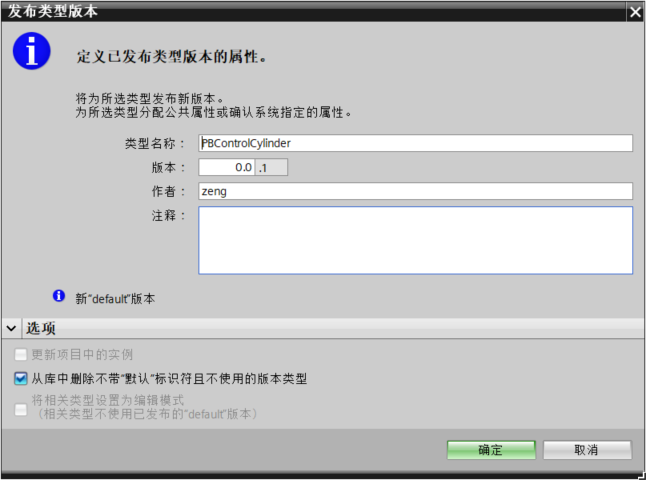

Publishing the Version: The configured panel needs to be published before it can be used. Click “Publish Version” to publish the configured panel. As shown in the figure below, after publishing, the corresponding panel will appear in the project library.

3

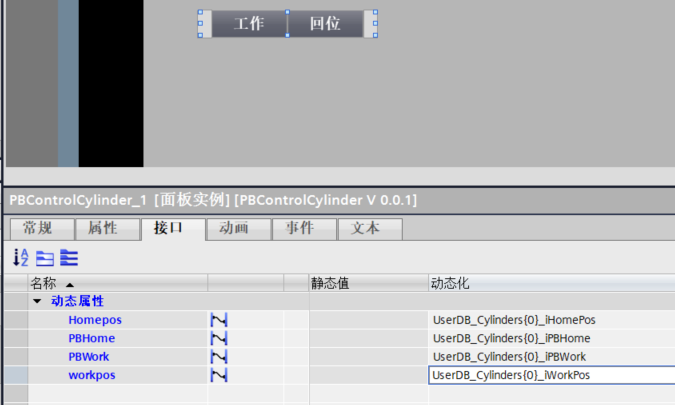

Using the Panel to Configure the Screen

Drag the configured panel from the project library to the touchscreen screen, and then in the panel properties, associate the actual variables in the dynamic options. This completes the corresponding configuration. When there are multiple cylinders, you can drag in the panel multiple times, and you can also adjust the panel size, then associate the dynamic variables.

4

Conclusion

It is important to note that some versions of the touchscreen may not support this functionality. For example, it was found that the Basic version of the touchscreen cannot drag the configured panel into the screen for configuration. Be cautious about the touchscreen version you choose.

Click below for the original text to read more about touchscreen configuration content!

Click below for the original text to read more about touchscreen configuration content! Scan the QR code to obtain materialsCase studies and past casesElectrical learning materials, manuals

Scan the QR code to obtain materialsCase studies and past casesElectrical learning materials, manuals Scan the QR code to add the author’s WeChatWeChat ID – z971946769Industrial control technology exchange, learning exchange

Scan the QR code to add the author’s WeChatWeChat ID – z971946769Industrial control technology exchange, learning exchange

Previous Recommendations

Learn PLC programming starting from the cylinder control case

Have you encountered the “pits” in using timers in S7-1200?

S7-200SMART series PLC communication between S7

Learn how to use encoders to measure motor speed in one article

S7-200SMART series PLC PROFINET communication

S7-200SMART series PLC USS communication with V20 inverter

How to build a custom Modbus communication block instruction

Quickly and efficiently complete the design of Modbus communication programs

S7-1200 Modbus communication case with Omron smart instruments

Learn how to apply PLC analog quantities through a case study

S7-1200 communication case with Modbus gateway